Automotive engine firewall with soundproof and heat-insulation performance

A vehicle engine and firewall technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex sound-absorbing cotton manufacturing process and increased manufacturing cost of rubber firewalls, and achieve low manufacturing cost, high sound insulation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

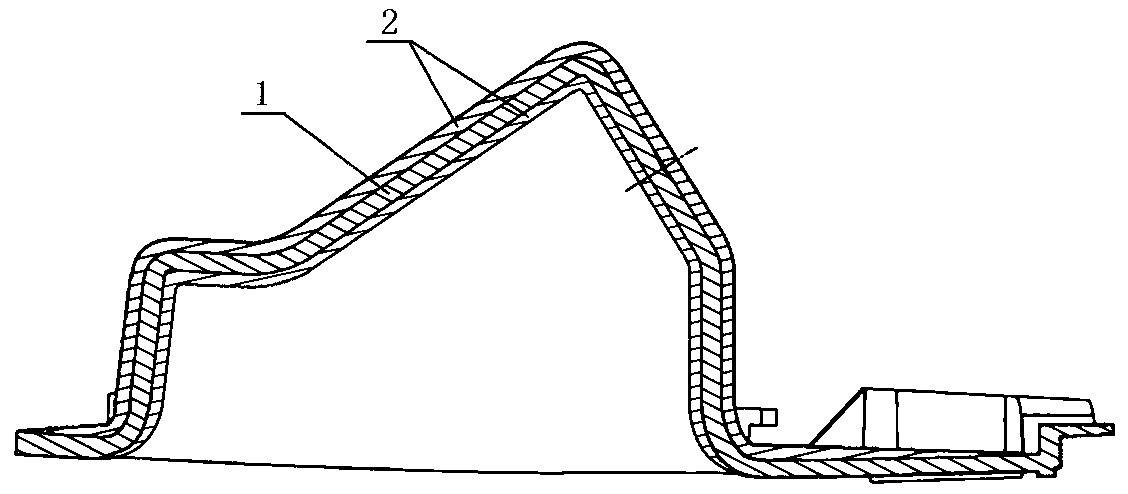

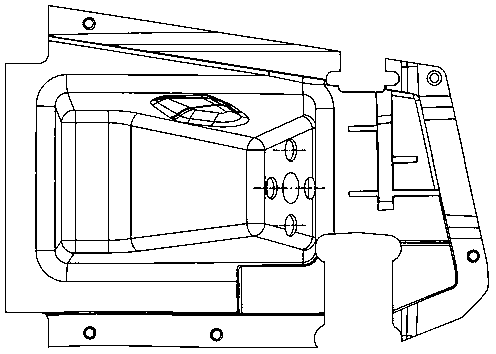

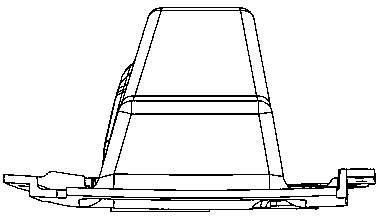

[0013] Such as figure 1 with figure 2 As shown, the vehicle engine firewall with sound insulation and heat insulation performance of the present invention includes a wall panel 1 whose shape is consistent with the shape of the vehicle engine, and the wall panel 1 is made of rubber material, and the commonly used rubber material is fire-resistant rubber. The outer surface of the wallboard 1 is covered with a polyurethane foam layer 2 . In this embodiment, the shape of the wall panel 1 is similar to the shape of a men's top hat, the top part of the hat is used to cover the engine, and the brim part of the hat is used for fixing between the engine cover and the vehicle frame.

[0014] In order to reduce the heat conduction to the wallboard, slow down the rubber aging speed, and increase the service life of the firewall, in this embodiment, the inner surface of the wallboard 1 is also covered with a layer of polyurethane foam layer 2 .

[0015] When in use, the vehicle eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com