Wind power generation permanent magnetic yaw-variable pitch hypocycloid reduction gear box

A hypocycloid and reduction box technology, applied in the direction of machines/engines, mechanisms for generating mechanical power, gear transmissions, etc., can solve the problems of complex structure, high price, long axial dimension, etc., and achieve good machining process performance , Uniform manufacturing process and short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below in conjunction with the accompanying drawings:

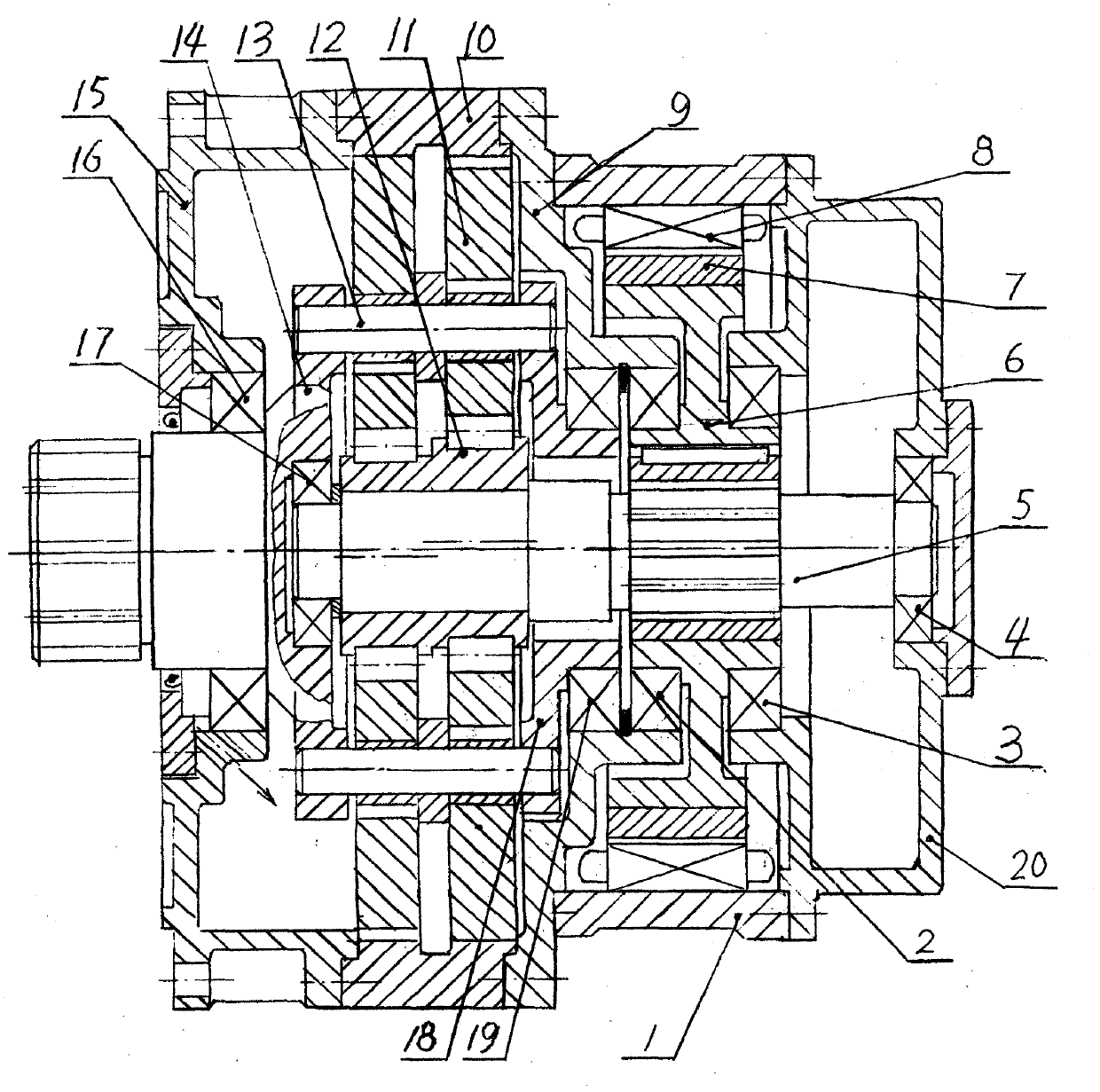

[0019] refer to figure 1 . A wind power generation permanent magnet yaw-variable pitch hypocycloidal reduction box, comprising a permanent magnet motor casing 1, a motor stator 8, a permanent magnet 7, a motor hollow rotor 6 and a single-stage cycloidal reduction component, the permanent magnet motor The front end of the housing 1 is connected to the embedded front end cover 9, the embedded front end cover 9 is connected to the hypocycloid ring gear 10, the hypocycloid ring gear 10 is connected to the base 15, and the rear end of the permanent magnet motor casing 1 is connected to The end cap 20 is characterized in that:

[0020] One side of the hollow rotor 6 of the motor is supported by the first bearing 2 in the inner hole of the embedded front end cover 9, and the other side is supported by the second bearing 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com