Chain drive device

一种链传动、滚子链的技术,应用在链传动装置领域,能够解决滚子、联结销耐久性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

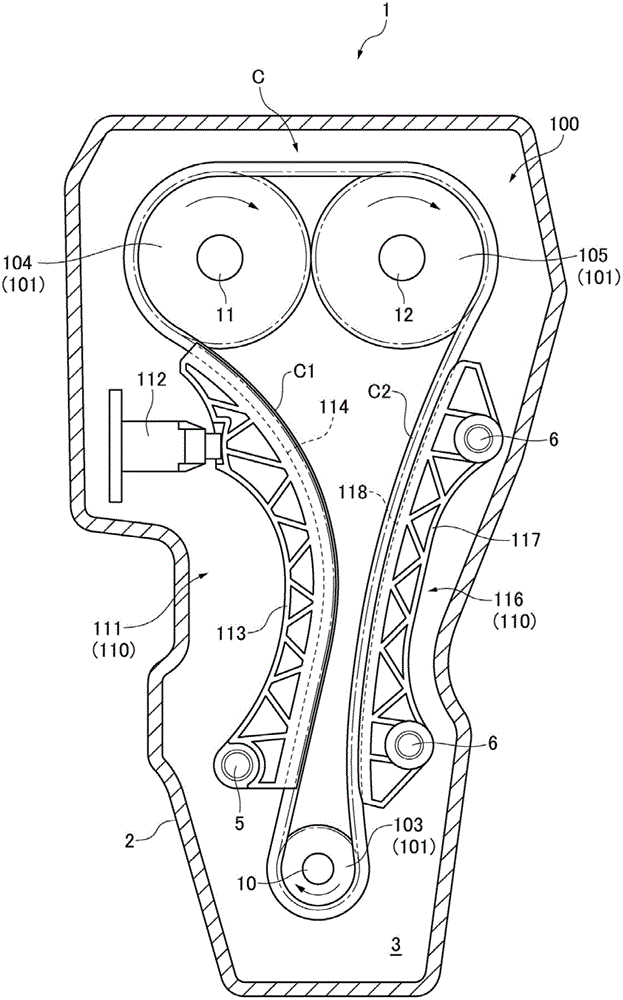

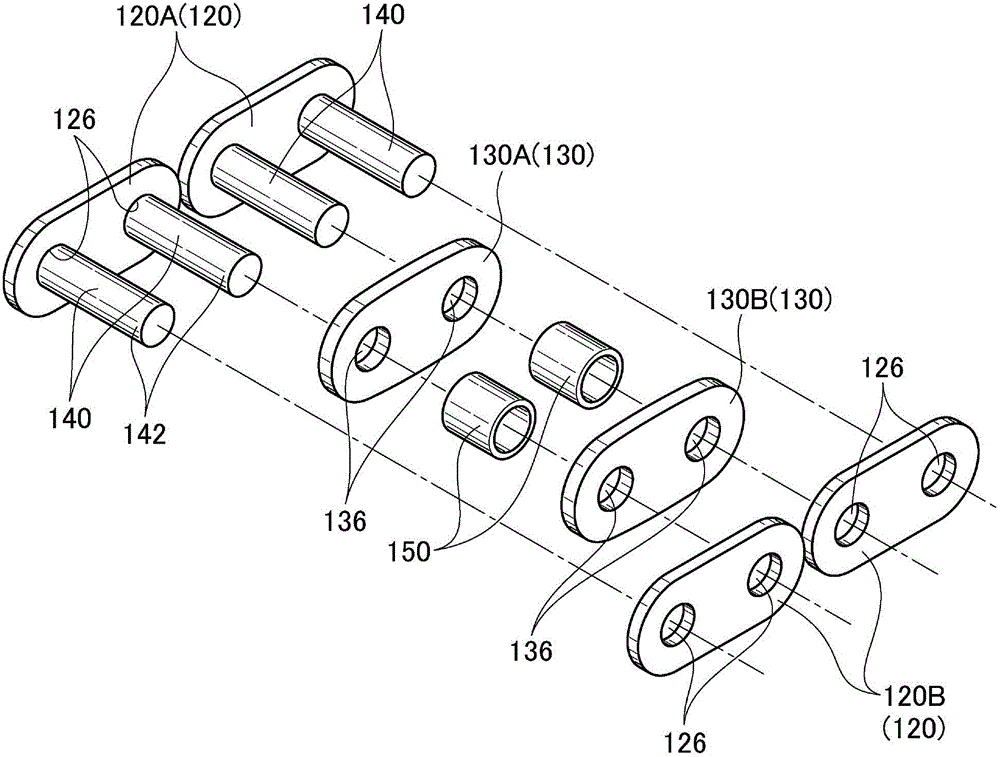

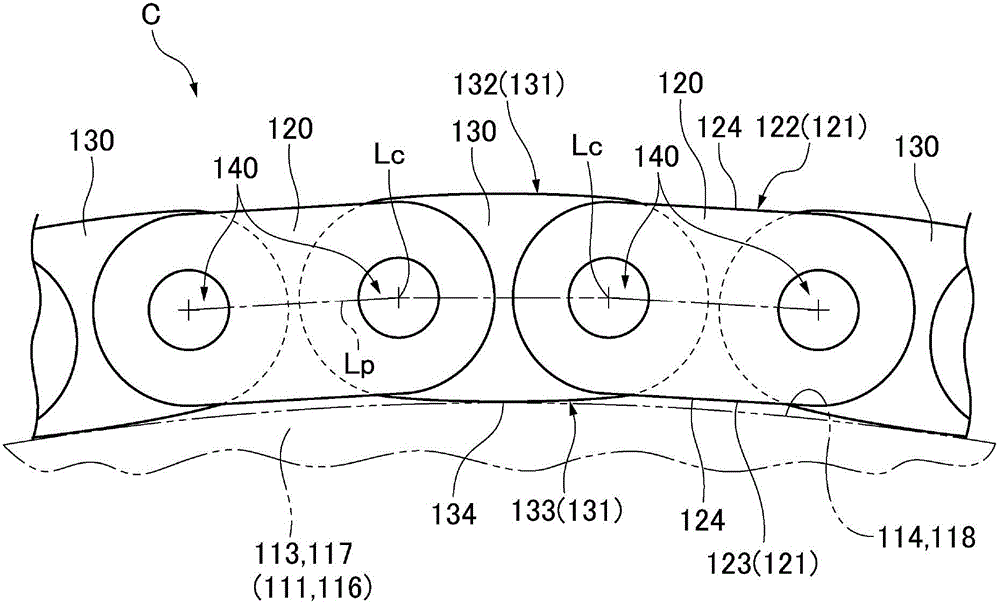

[0053] The chain transmission device of the present invention has a bushless roller chain, a plurality of sprockets, and a chain guide. In the bushless roller chain, a pair of outer link plates and a pair of outer link plates arranged between the pair of outer link plates The inner chain plates are connected by connecting pins that directly support a pair of inner chain plates rotatably and directly support rollers disposed between the pair of inner chain plates, and are alternately linked along the chain travel direction; The sprocket has a plurality of sprocket teeth capable of engaging each roller; the chain guide has a sliding contact for the advancing bushless roller chain while guiding the bushless roller chain in the direction of chain travel On the surface, the bushless roller chain is lubricated by lubricating oil, and the coupling pin is set on the outer chain plate so that it cannot move relatively, and is inserted into the through hole set on the inner chain plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com