Method of measuring outer diameter tolerance and ovality of thin-walled loop

A measurement method and ovality technology, which is applied in the field of measurement of the outer diameter tolerance and ovality of thin-walled ferrules, and can solve problems affecting the quality of thin-walled ferrules, measurement deformation of thin-walled ferrules, and failure to reach the measurement range. , to achieve the effect of simple and practical measurement method, reduce measurement work intensity and improve measurement work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

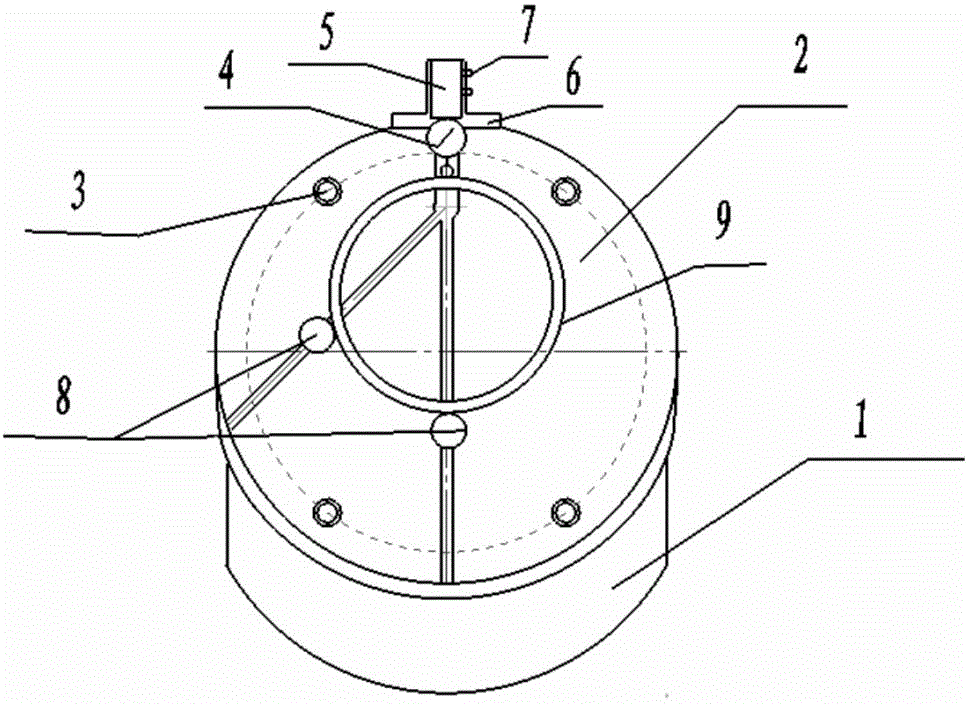

[0015] The invention relates to a method for measuring the outer diameter tolerance and ellipticity of a thin-walled ferrule. The measuring method can measure the outer diameter tolerance and ellipticity error of the thin-walled ferrule through one detection, and is especially suitable for larger outer diameters. The thin-walled ferrule is also suitable for thin-walled ferrules with small outer diameters, and it can also be used as a reference for other types of ferrules.

[0016] Set the outer diameter of the processed thin-walled ferrule 9 and the standard thin-walled ferrule to be ФD=290 mm, the upper deviation of the outer diameter of the thin-walled ferrule 9 to be tested is 0, and the measured thin-walled ferrule 9 The lower deviation of the outer diameter is -h=-0.018 mm, and the ellipticity error of the outer diameter of the thin-walled ferrule 9 under test is h 1 = 0.019mm, the wall thickness of the measured thin-walled ferrule 9 = 3.5mm, and the upper and lower devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com