Testing table and testing method for reciprocating-type piston rod sliding sealing performance testing

A technology of sliding seal and piston rod, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the rate of increase and deceleration of the fluid, can solve the problems of lack of performance test bench and so on, so as to increase reliability and credibility degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

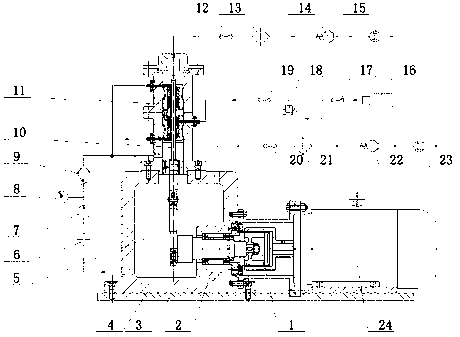

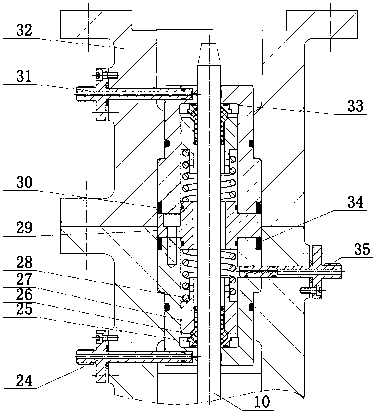

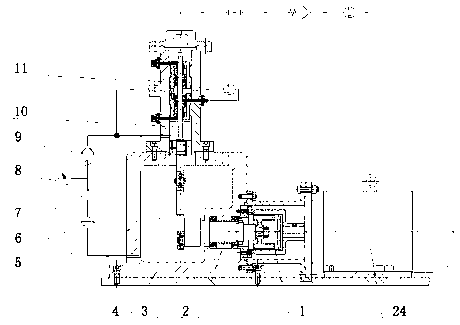

[0012] The present invention is a reciprocating piston rod sliding sealing performance testing test bench and testing method thereof, such as figure 1 , figure 2 , image 3 As shown, the test bench mainly includes a motor 45, a magnetic transmission coupling 1, a transmission shaft 2, a crankshaft linkage mechanism 5, a crankcase 4, a cylinder block 31, and a sliding sealing device 11. The motor 45 passes through the magnetic transmission coupling 1 Drive the transmission shaft 2 to drive the crank linkage mechanism 5, and then convert the linear reciprocating motion of the piston rod 10 through the sliding rod 35 and the guide sleeve 36 in the guiding mechanism. The first sliding sealing device 11a and the second sliding sealing device 11b adopt the up and down Symmetrically arranged and fitted on the piston rod 10, the connection joint surfaces of the sleeves 27 of the first sliding sealing device 11a and the second sliding sealing device 11b and the sealing member 26, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap