Method and system for adaptively adjusting working voltage of chips

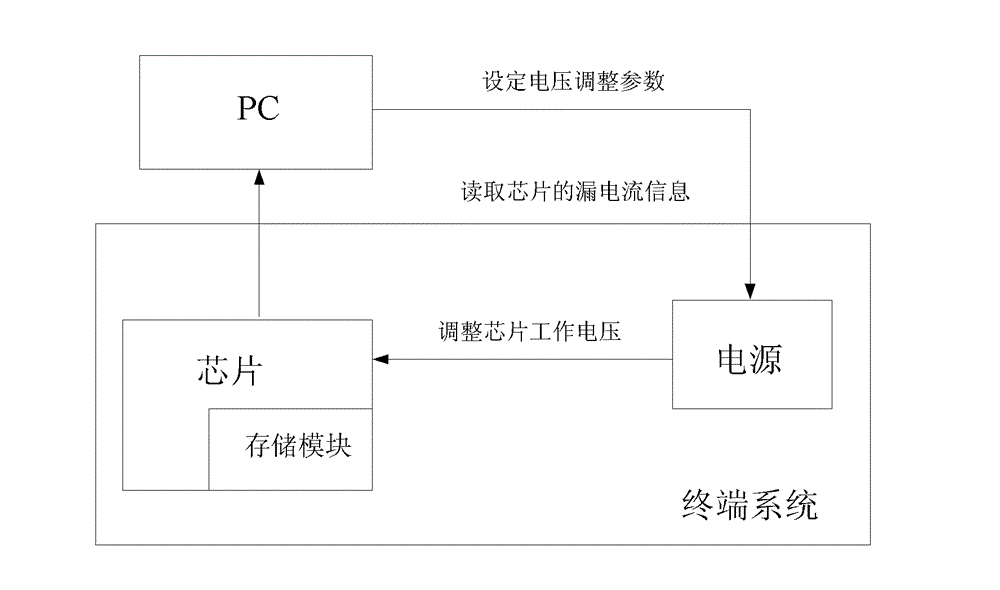

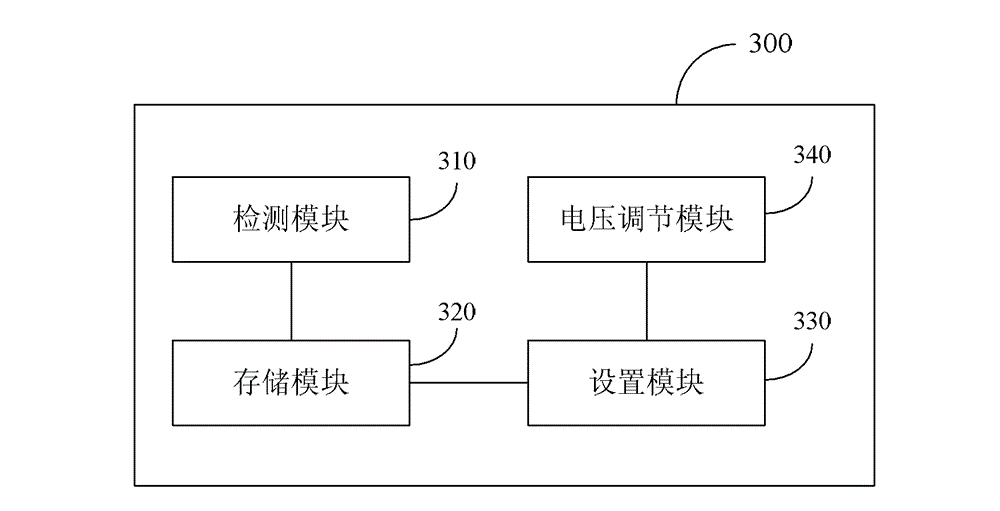

A technology of self-adaptive adjustment and working voltage, applied in information storage, static memory, digital memory information, etc., can solve the problems of increasing chip production cost and chip power consumption, and achieve the effect of reducing production test cost and controlling power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The leakage current of the chip (leakage) has a certain corresponding relationship with the working voltage of the chip

[0075] The corresponding relationship between the leakage current of the chip and the working voltage is obtained through a large number of experiments on the test machine. Specifically, a curve of the leakage current and the working voltage can be fitted through the experimental data.

[0076] It can be seen that a chip with a small leakage current requires a large operating voltage, and a chip with a large leakage current requires a smaller operating voltage. Based on this, the present invention proposes a method for adaptively adjusting the operating voltage of the chip, which is specifically divided into two stages:

[0077] Ⅰ. Chip testing stage

[0078] Figure 4 This is a schematic diagram of the principle of obtaining the leakage current value in this embodiment. Reference Figure 4 , When the chip is tested for ATE, the leakage current of the chip i...

Embodiment 2

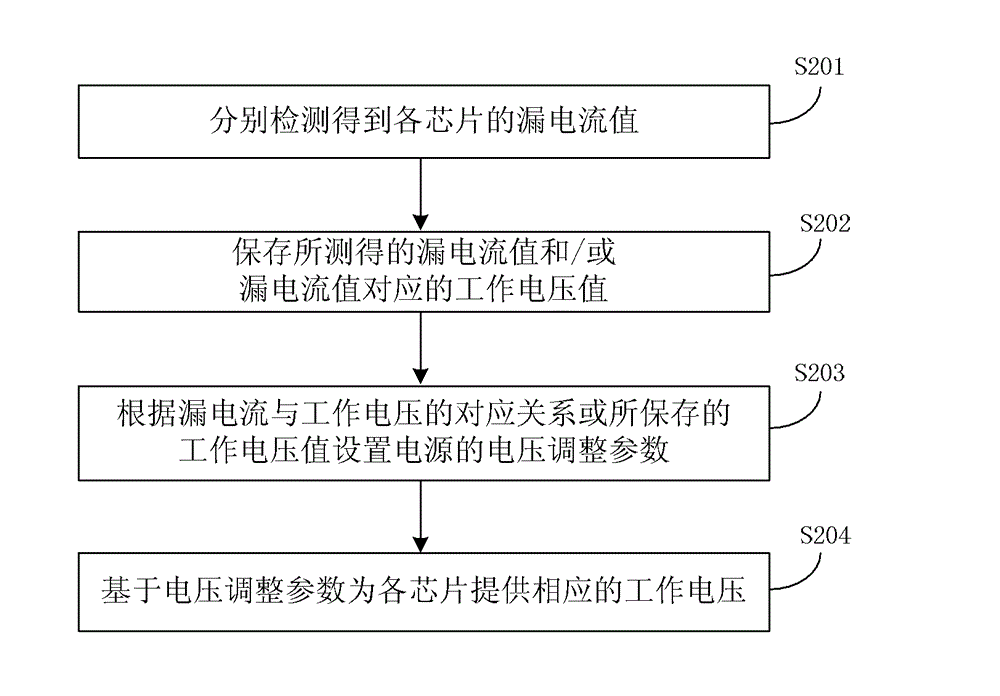

[0084] Such as Image 6 As shown, another method for adaptively adjusting the operating voltage of a chip provided in this embodiment includes the following steps:

[0085] S601: Scan all possible working voltages to determine the lowest working voltage of each chip;

[0086] Scan to get a set of voltage values (range) to determine the lowest operating voltage of each chip.

[0087] There are also various methods for scanning the lowest voltage of the chip, mainly including the following two:

[0088] 1) Put multiple chips on the actual system board, run a special test program, gradually adjust the operating voltage of the chip, and observe the operating status of the chip to determine the final operating voltage.

[0089] 2) Put the chip on the automatic test platform, drive a special test excitation by ATE, and determine the working voltage by shamoo.

[0090] S602: Save the minimum operating voltage value of each chip;

[0091] Save it in storage media, such as eFuse, electrically er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com