A computer button without clipping feet and scissor feet, and assembling equipment and method

A scissor foot, computer technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of reducing strength, high mold manufacturing cost, affecting support strength, etc., to reduce mold manufacturing costs, reduce left and right shaking, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

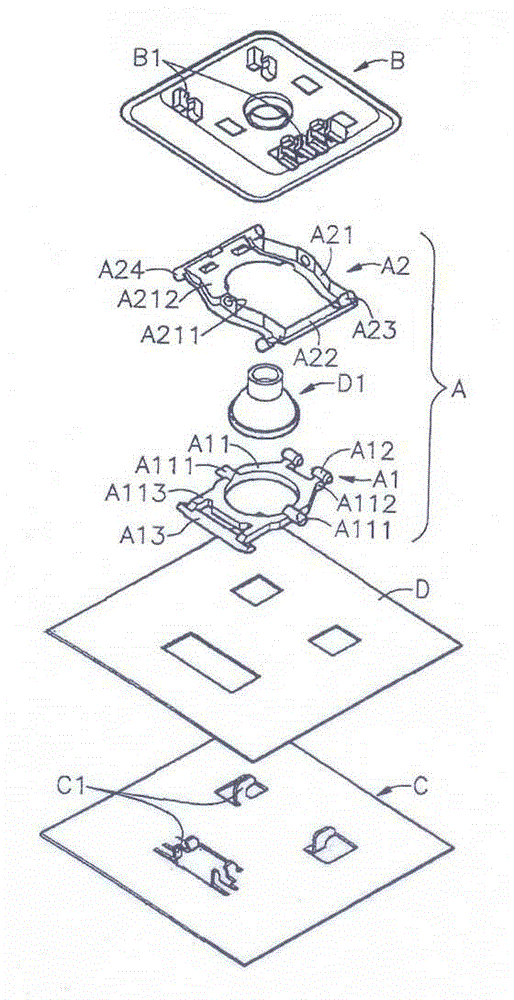

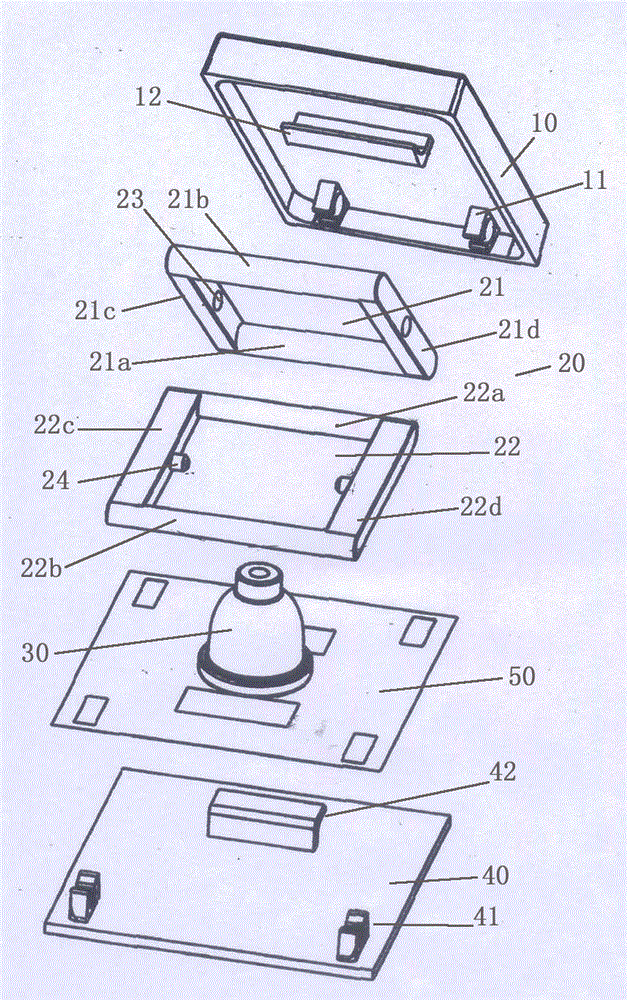

[0029] Such as Figure 2-4 As shown, a computer button without clipping scissor feet of the present invention includes: a key cap 10, a scissor foot 20, an elastic silicone body 30, a button bottom plate 40 and a printed circuit film 50 covering the button bottom plate 40, The top of the elastic silicone body 30 passes through the frame hole of the scissors feet 20 and is placed on the bottom surface of the button cap 10. The bottom of the elastic silicone body 30 is located on the key switch of the printed circuit film 50. The scissors feet 20 are formed by the outer frame body 21 and the inner The frame body 22 is composed of two parts. The inner frame body 21 and the outer frame body 22 are combined by shafts and holes. free spins;

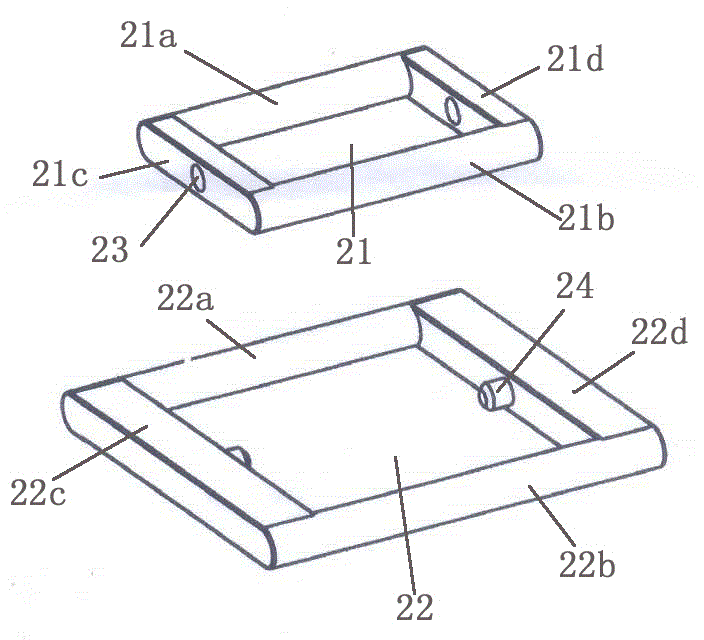

[0030] Described inner frame body 21 is a frame body of symmetrical shape, and inner frame body 21 is the rectangular frame body that is formed by interconnecting inner frame forearm 21a, inner frame rear arm 21b, inner frame left arm 21c, inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com