Vehicle wheel

A wheel and rim technology, applied in the direction of wheels, spoked wheels, wheel cover discs, etc., can solve the problem of short stroke, insufficient adjustment force, not allowed to be used in the radial direction caused by centrifugal force to move from the inner open position to Issues such as covers in the outer closed position to achieve good thermal contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

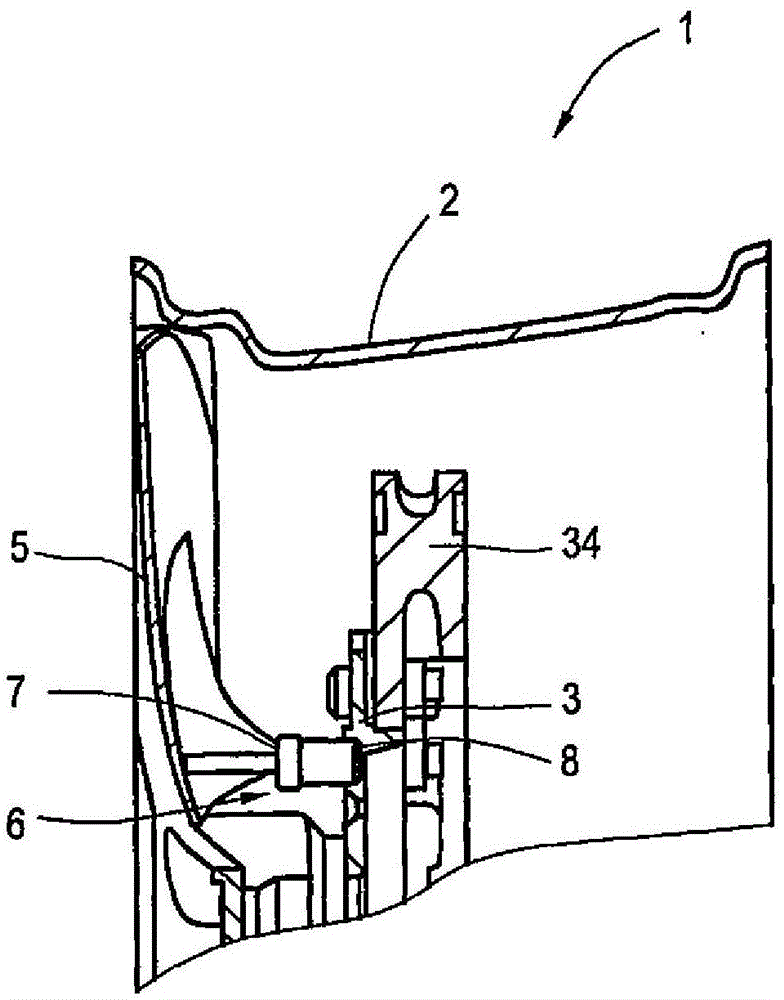

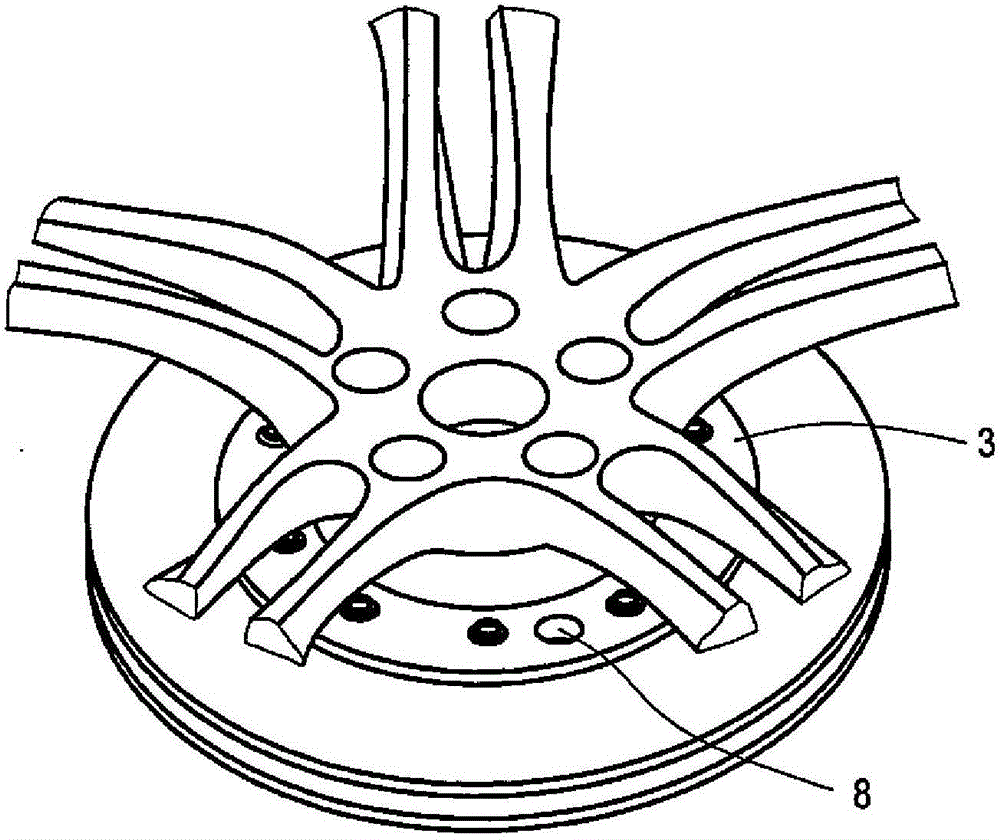

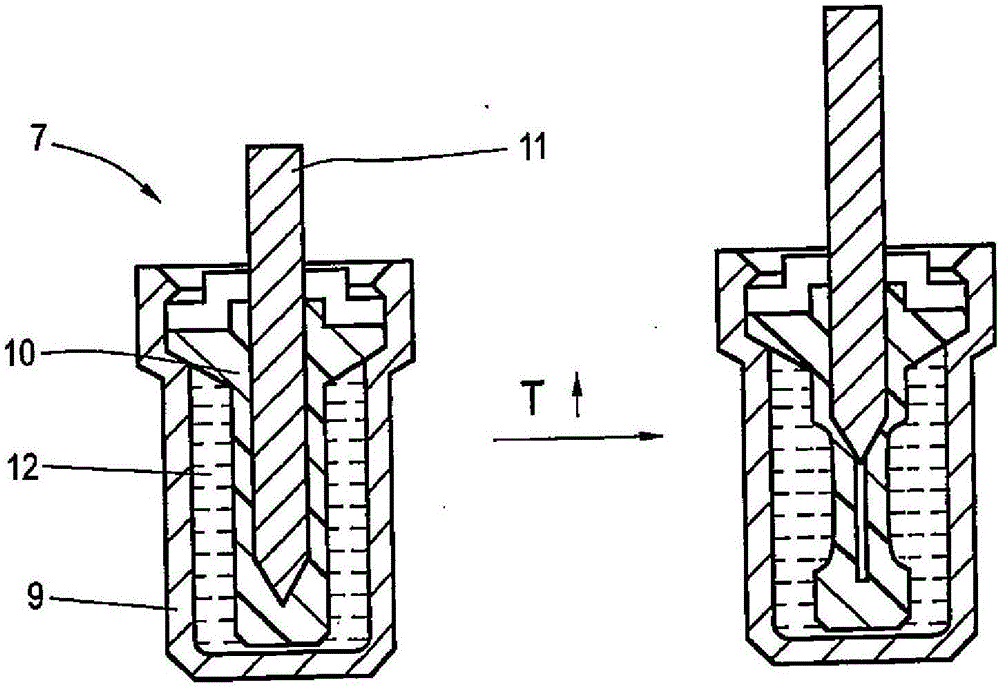

[0038] figure 1 A wheel 1 according to the invention is shown, comprising a rim 2 , a brake disc drum 3 fastened to the rim and a brake disc 34 fastened to the brake disc drum. See for example the following Figure 4 The rim 2 has various perforations 4 , for which a plate-shaped cover 5 is respectively assigned, by means of which the perforations can be closed or opened. The individual covers 5 are mounted pivotally movable on the rim 2 via pivot axes, which will be discussed later. In order to be able to deflect the cover into the open position due to the thermal conditions on the brake disc 34 for ventilation via the perforations 4 on the rim side, a thermally controlled element in the form of an expanding material work element 7 is provided in the wheel according to the invention. An adjustment element 6 is arranged on the brake disk fastening drum 3 and is thus thermally coupled to the brake disk 34 . Because the brake disc is directly arranged on the brake disc fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com