Liquid flow path control device for drive device for vehicle

A liquid flow path and drive device technology, applied in the field of liquid flow path control devices, can solve problems such as lubrication and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

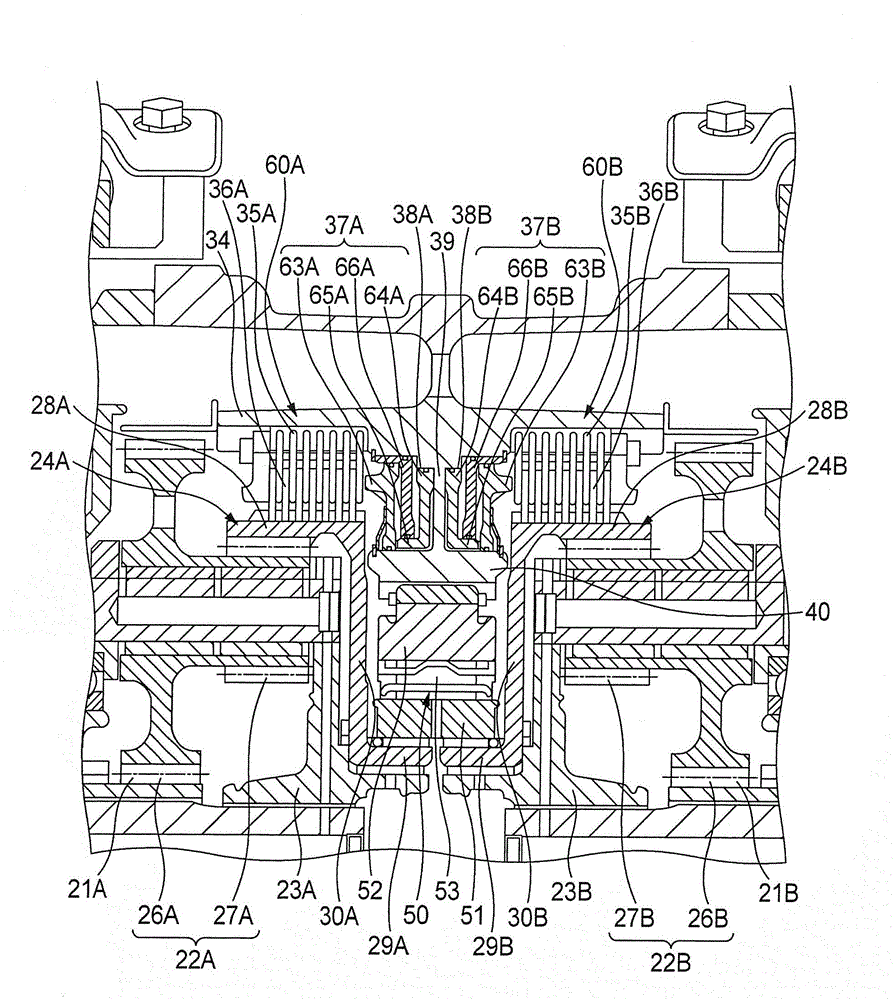

[0204] Next, refer to Figure 22 , the second embodiment of the present invention will be described. It should be noted that the second to sixth embodiments to be described later are embodiments in which the configuration of the hydraulic circuit of the first embodiment is partially changed, and the same members are denoted by the same reference numerals and description thereof will be omitted.

[0205] The hydraulic circuit 71A of the second embodiment is different from the hydraulic circuit 71 of the first embodiment in that the overflow drain pipe 86 of the relief valve 84 is not connected to the oil bottom where the oil suction port 70a of the electric hydraulic pump 70 is arranged. The shell 80 is connected to the reservoir 79 disposed at a position higher than the oil pan 80 in the vertical direction. In addition, the oil reservoir side end portion 86 a of the overflow drain pipe 86 is arranged at a position higher than the vertically uppermost portion of the reservoir ...

no. 3 approach

[0208] Next, refer to Figure 23 , the third embodiment of the present invention will be described.

[0209] The hydraulic circuit 71B of the third embodiment is different from the hydraulic circuit 71 of the first embodiment in that the brake oil circuit switching valve 74 of the first embodiment is not provided, and the brake oil circuit 77 is directly connected to the solenoid valve 83 The first radial hole 183 (refer to Figure 8 )connect.

[0210]In this hydraulic circuit 71B, by controlling the operation mode of the electric hydraulic pump 70 and the energization and de-energization of the electromagnetic element 174 in the same manner as the hydraulic circuit 71 of the first embodiment, it can be compared with the hydraulic circuit of the first embodiment. 71 similarly controls the hydraulic brakes 60A, 60B into the disengaged state, the weakly engaged state, and the engaged state, and can always lubricate and cool the lubricating and cooling unit 91 . It should be n...

no. 4 approach

[0212] Next, refer to Figure 24 , the fourth embodiment of the present invention will be described.

[0213] The hydraulic circuit 71C of the fourth embodiment is different from the hydraulic circuit 71 of the first embodiment in that the solenoid valve 83 of the first embodiment is not provided, and the oil chamber 74c of the brake oil circuit switching valve 74 is directly connected to the hydraulic circuit 71 of the first embodiment. The second line oil passage 75b of the line oil passage 75 is connected.

[0214] In this hydraulic circuit 71C, the electrohydraulic pump 70 can operate in three modes, namely, an extremely low pressure mode in addition to the high pressure mode and the low pressure mode, and the force of the spring 73b of the oil circuit switching valve 73 is set as follows: When the electric hydraulic pump 70 operates in the low pressure mode and the extremely low pressure mode, under the action of the hydraulic pressure of the pipeline oil passage 75 inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com