Novel efficient energy-saving cylinder fixation machine

A high-efficiency and energy-saving technology of a drum-fixing machine, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of low dehydration efficiency and energy efficiency ratio, low tea aroma, and burnt edge of green leaves, so as to improve the uniformity of throwing, increase the contact time, Improves the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

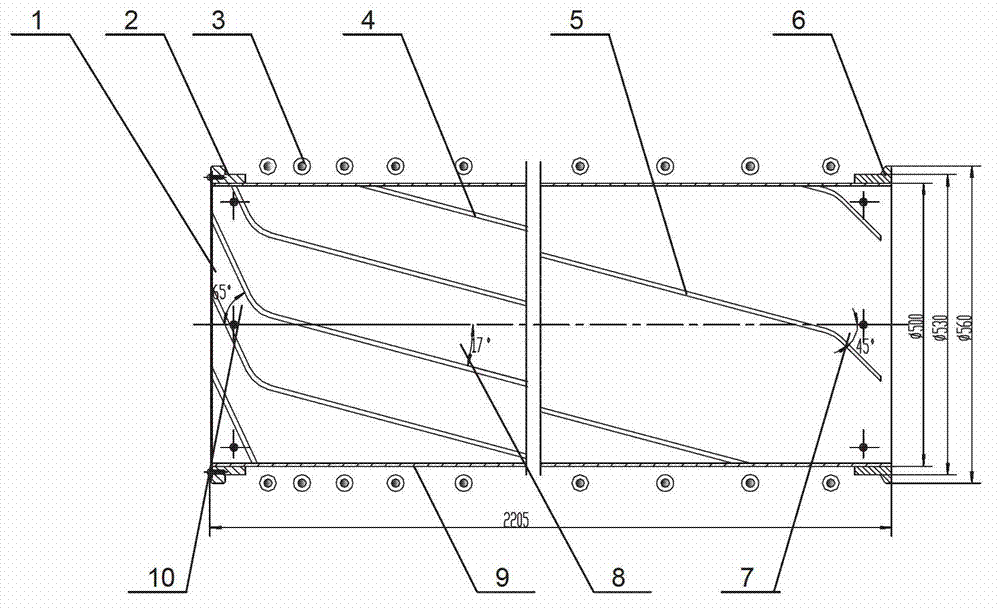

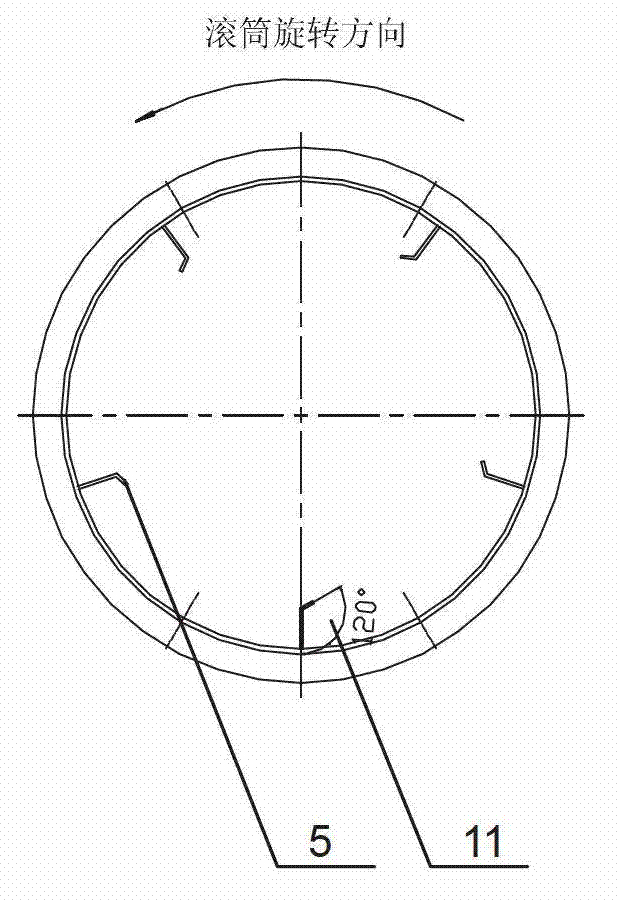

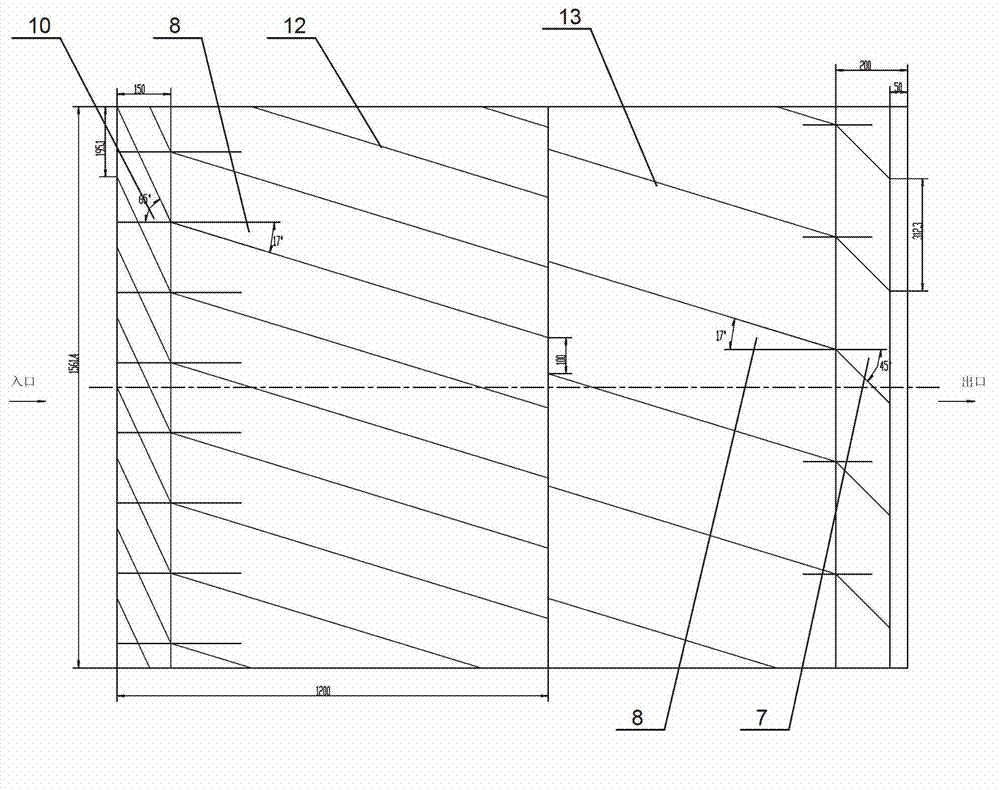

[0021] refer to figure 1 and figure 2 , The barrel parts of the drum cleaning machine, including the annular heat pipe 3, the barrel 9, the front guide vane 4, the rear guide vane 5, the front rolling ring 2, the rear rolling ring 3 and the air-permeable disk 1.

[0022] The front rolling ring 2 is installed on the inlet end of the cylinder body 9, and is fastened to the cylinder body by bolts; the rear rolling ring 3 is installed on the outlet end of the cylinder body 9, and is fastened to the cylinder body by bolts; the cylinder body 9 passes through The front rolling ring 2 and the rear rolling ring 3 are connected with the shell of the drum fixing machine (not shown in the figure), and generate rotational motion under the action of the driving mechanism. The rotating speed of the drum in this embodiment is 31.5rpm, which is slightly lower than that of the same sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com