Side-hung tunnel fire-extinguishing robot mechanical system

A fire extinguishing robot and mechanical system technology, applied in the field of side-mounted tunnel fire extinguishing robot mechanical system, can solve problems such as endangering the life and property safety of disaster relief personnel and surrounding residents, and blank research on fire extinguishing robots, and achieves compact structure, strong sealing, and The effect of fewer entrances and exits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

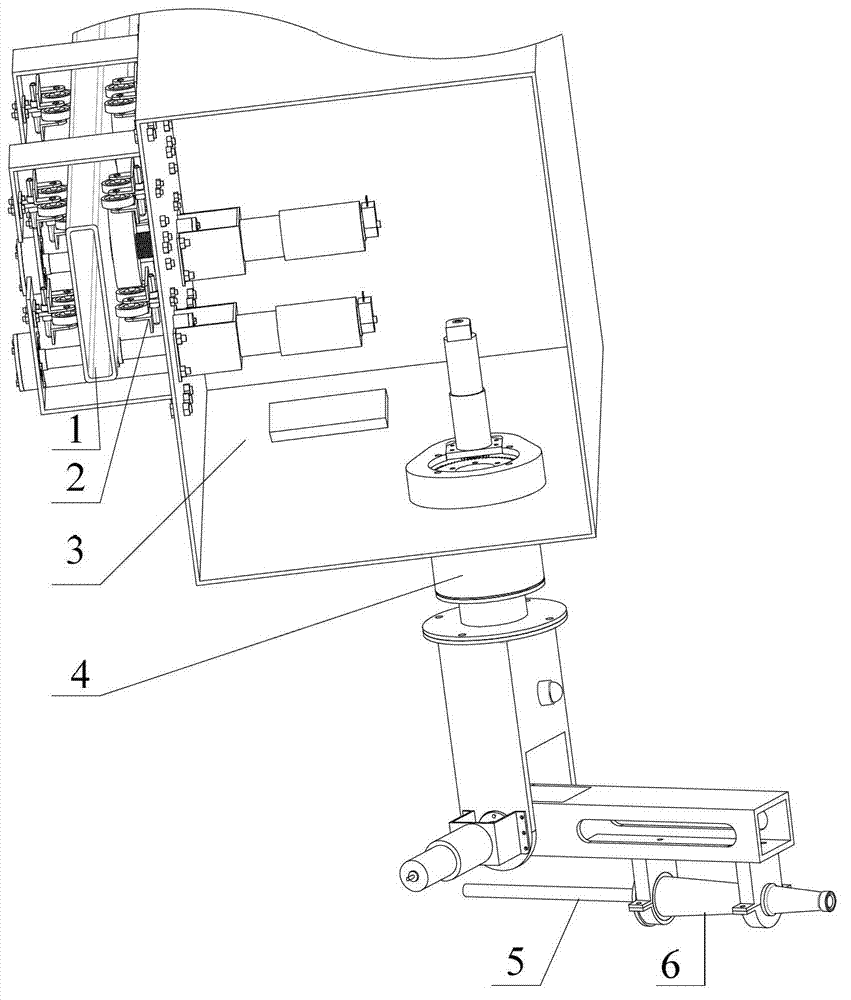

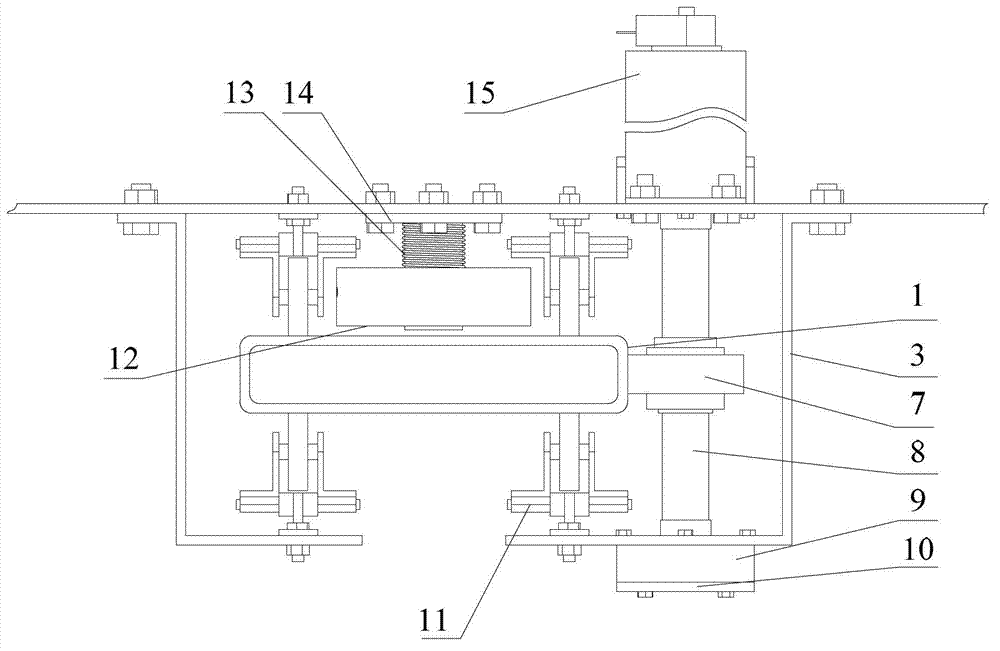

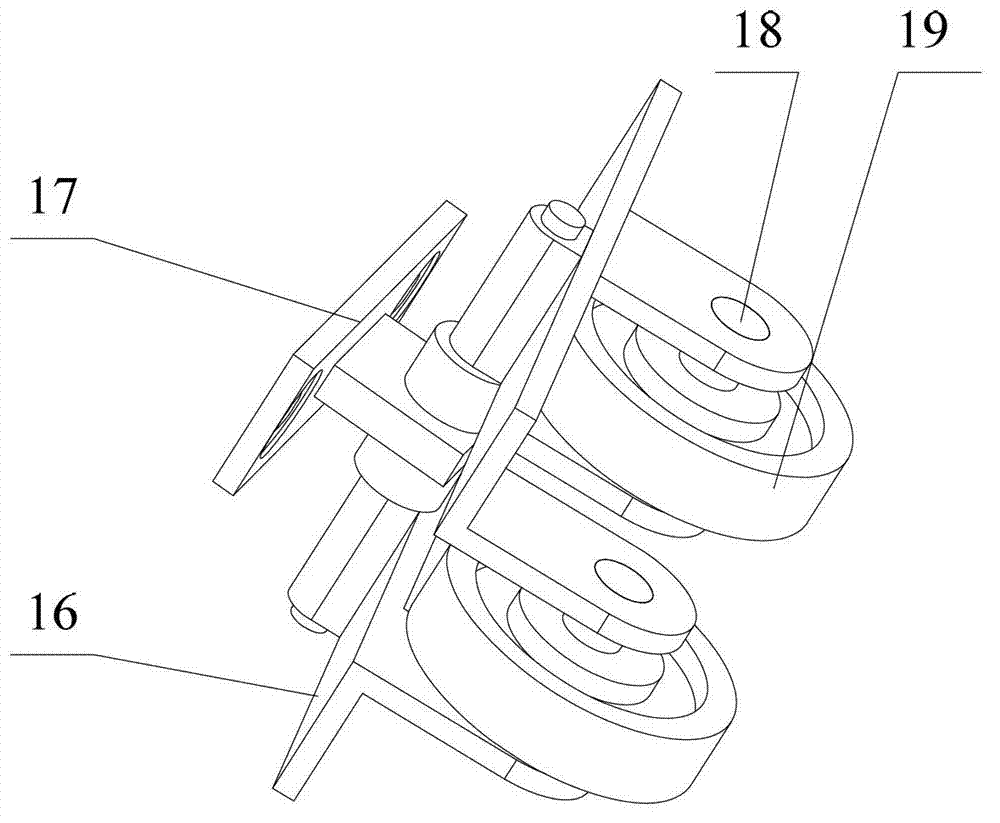

[0016] Such as Figure 1-5 As shown, a side-mounted tunnel fire-fighting robot mechanical system includes a box body 3, a track 1, a mobile device 2 and a fire-extinguishing system 4; the track 1 is installed on the upper part of the side of the tunnel, and the box body 3 moves The device 2 is installed on the track 1, and the fire extinguishing system 4 is fixed on the box body 3. Described moving device 2 comprises two identical drive systems, and drive system comprises driving wheel 7, output shaft 8, support sleeve 9, end bearing cover 10, support wheel 11, electromagnet 12, spring 13, support plate 14 and Motor 15, wherein support wheel 11 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com