Magnetic separation device and method

A magnetic separation device and magnetic pole technology, applied in the fields of magnetic separation, small magnetic separation devices, and magnetic separation devices, can solve problems such as difficulty in mastering, poor precision and accuracy, achieve high precision and accuracy, and avoid analysis errors , the effect of avoiding the loss of magnetic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: magnetic separation device of the present invention

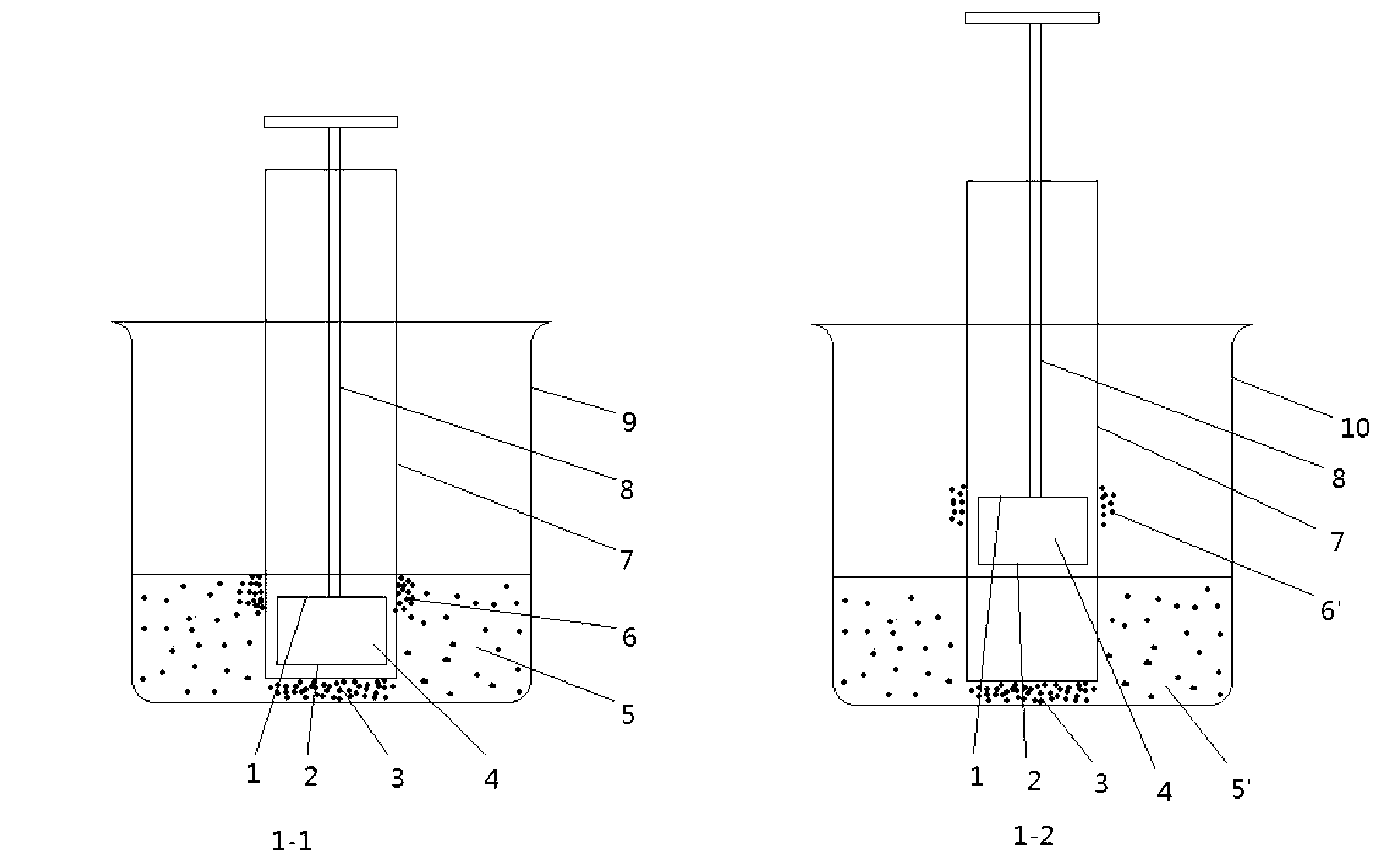

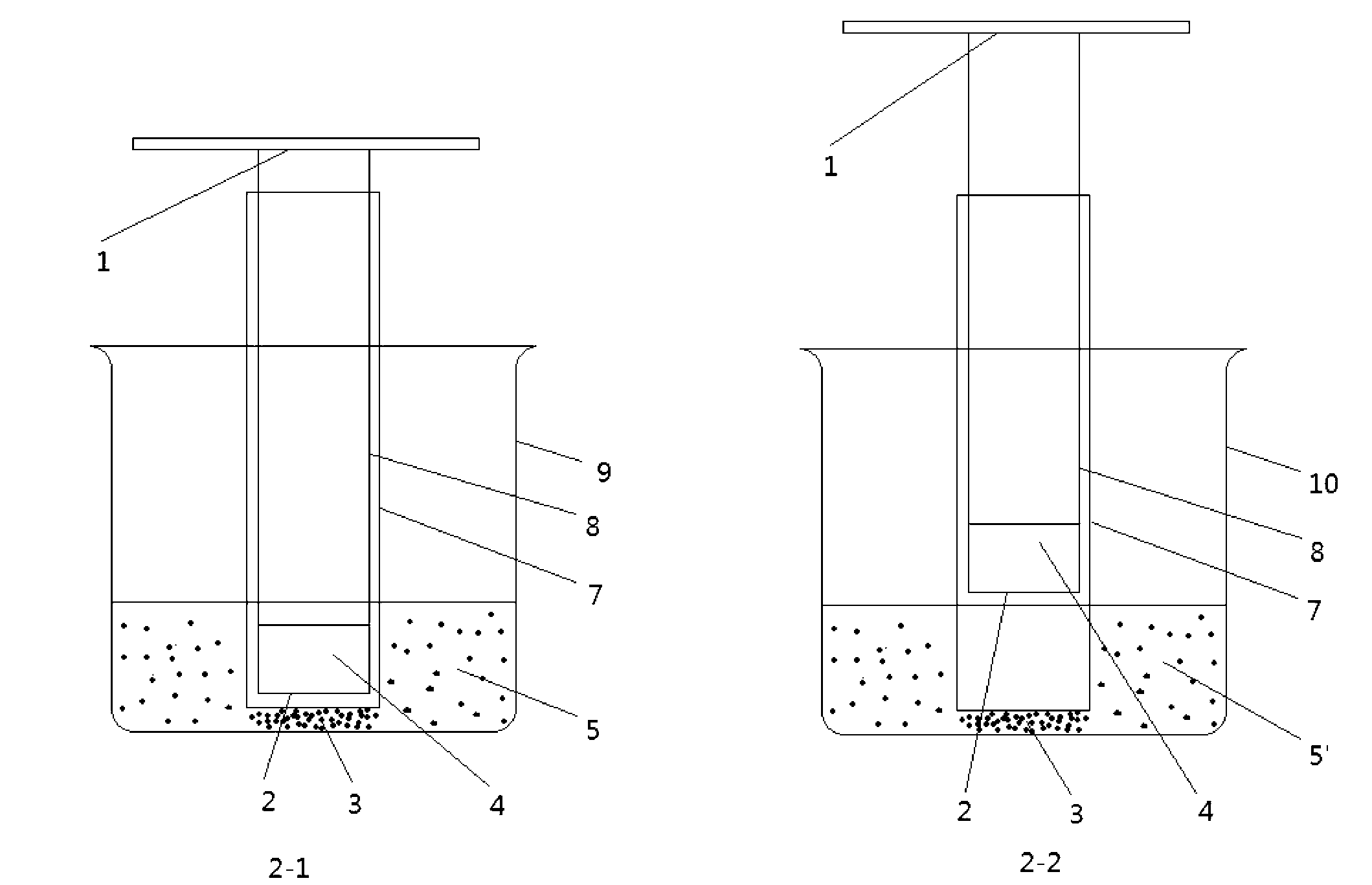

[0042] figure 2 is a schematic structural view of a magnetic separation device according to an embodiment of the present invention, wherein diagram 2-1 is a schematic diagram of the magnetic separation device when it adsorbs magnetic particles, Figure 2-2 It is a schematic diagram of the magnetic separation device releasing magnetic particles.

[0043] Such as diagram 2-1 The magnetic separation device of the present invention shown includes a combined magnet (composed of a permanent magnet (4) and a ferromagnetic body (8) that is substantially equal in diameter to the permanent magnet (4) through magnetic connection), and a non-magnetic a glass jacket (7), and a first container (9) for holding a mixture suspension (5) of magnetic and non-magnetic particles. One pole of the permanent magnet (4) is magnetically connected to one end of the ferromagnet (8), the other pole of the permanent magnet (4...

experiment example 1

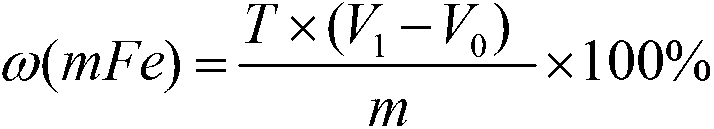

[0045] Experimental example 1: Magnetic separation device of the present invention and the magnetic iron measuring method using this device

[0046] 1. Experimental part

[0047] 1. Magnetic separation device

[0048] use as figure 2 In the magnetic separation device shown, the permanent magnet (4) is a short cylindrical permanent magnet with a diameter of 1.5cm and a height of 0.8cm, and the measured magnetic field strength (outside the casing) is (900±100)×10 3 / 4π(A / m); the ferromagnet (8) is an iron pipe with a handle, the length of the iron pipe is 10cm, the outer diameter of the iron pipe is 1.3cm, the thickness of the iron pipe is 0.2cm, the length of the handle is 8.5cm, and the width is 1.4cm; the glass jacket ( 7) It is a flat-bottomed glass tube with a height of 9.5cm, an inner diameter of 1.7cm, and an outer diameter of 1.9cm; the first container and the second container are 50mL small flat-bottomed beakers with a diameter of 4.8cm, a height of 5.8cm, an outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com