Bearing washing and maintaining machine

A bearing cleaning and maintenance machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Failures, efficiency improvements, wide application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the present invention.

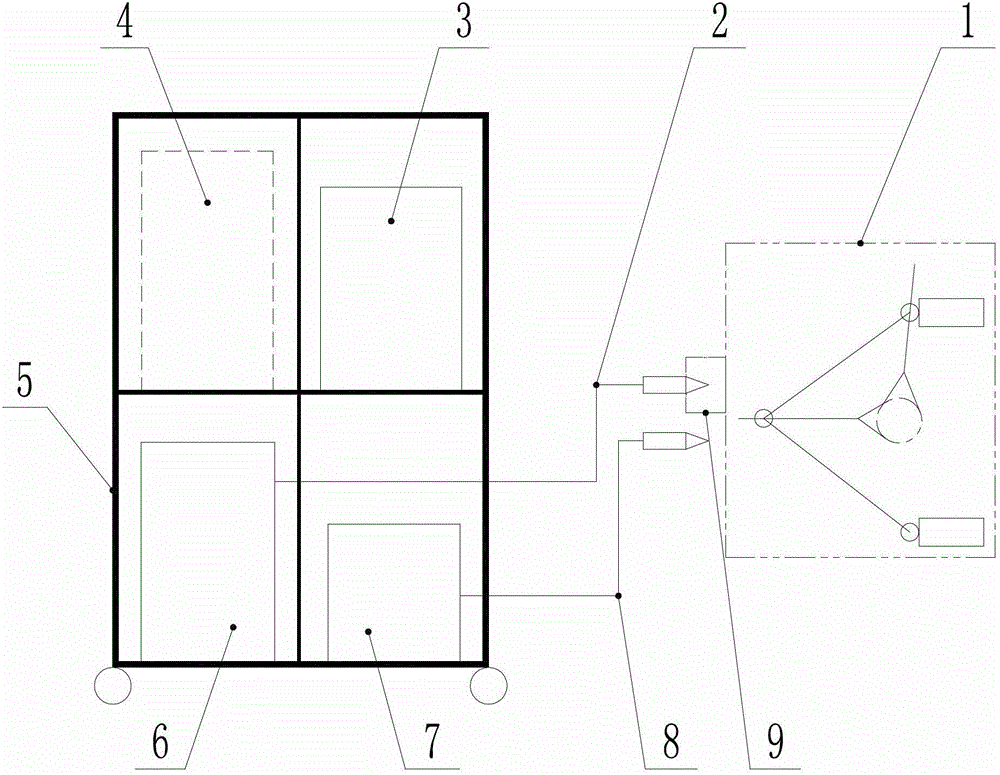

[0043] Such as figure 1 As shown, a bearing cleaning and maintenance machine includes an angle holder 1 and a cleaning system.

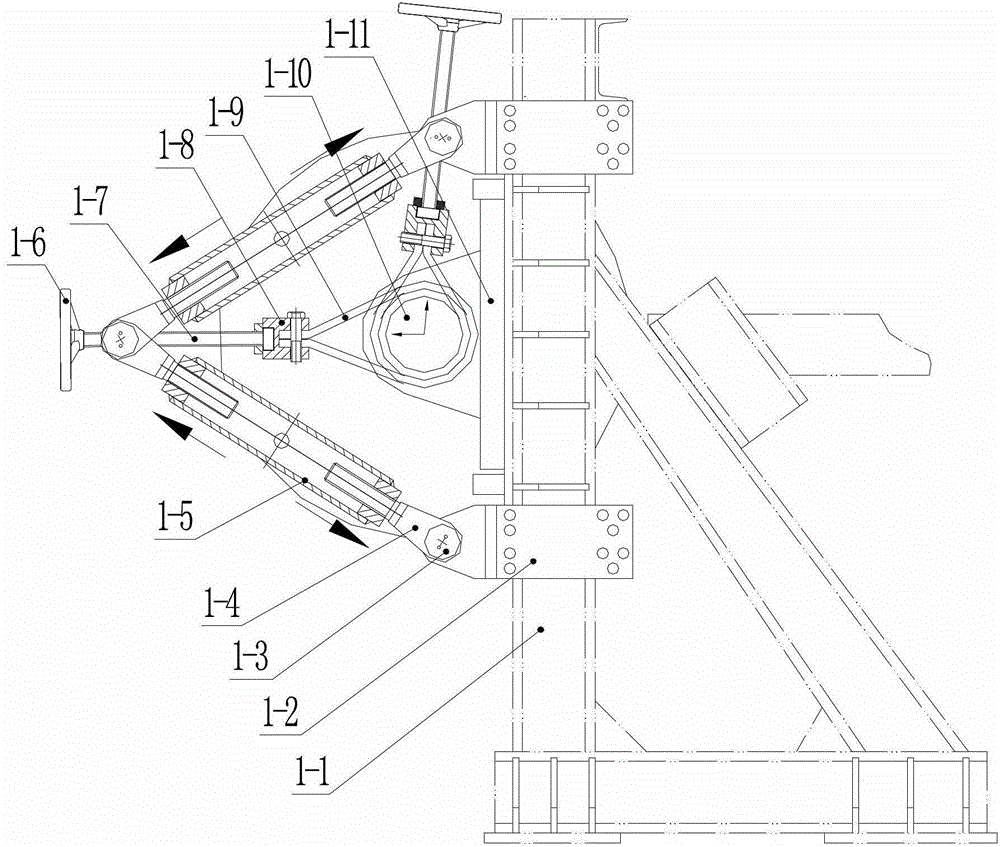

[0044] Such as figure 2 As shown, the angle fixer 1 includes two fixing frames 1-2 and two adjusting arms 1-5; the fixing frames 1-2 are fixed on the equipment used to fix the bearing seat 1-11, and the two fixed The frame 1-2 is located on both sides of the bearing seat 1-11; between the adjusting arm 1-5 and the fixed frame 1-2, and between the two adjusting arms 1-5 are hinged by a connecting shaft 1-3; the connecting shaft 1-3 A screw hole is provided in the radial direction of the screw hole, and the screw hole is matched with an adjusting screw 1-7, and one end of the adjusting screw 1-7 is connected with a winding piece, and the winding piece is set on the piece to be fixed;

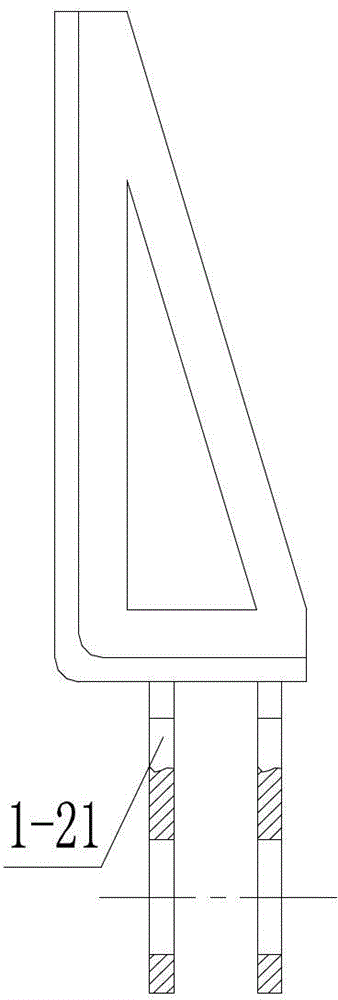

[0045] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com