Sheet cutting device

A technology for cutting devices and sheets, which is applied in the direction of shearing devices, driving devices, and accessories of shearing machines, etc. It can solve problems such as inconvenient production and use, and irregular cutting lines, so as to offset the reaction force and avoid uneven cutting lines. neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

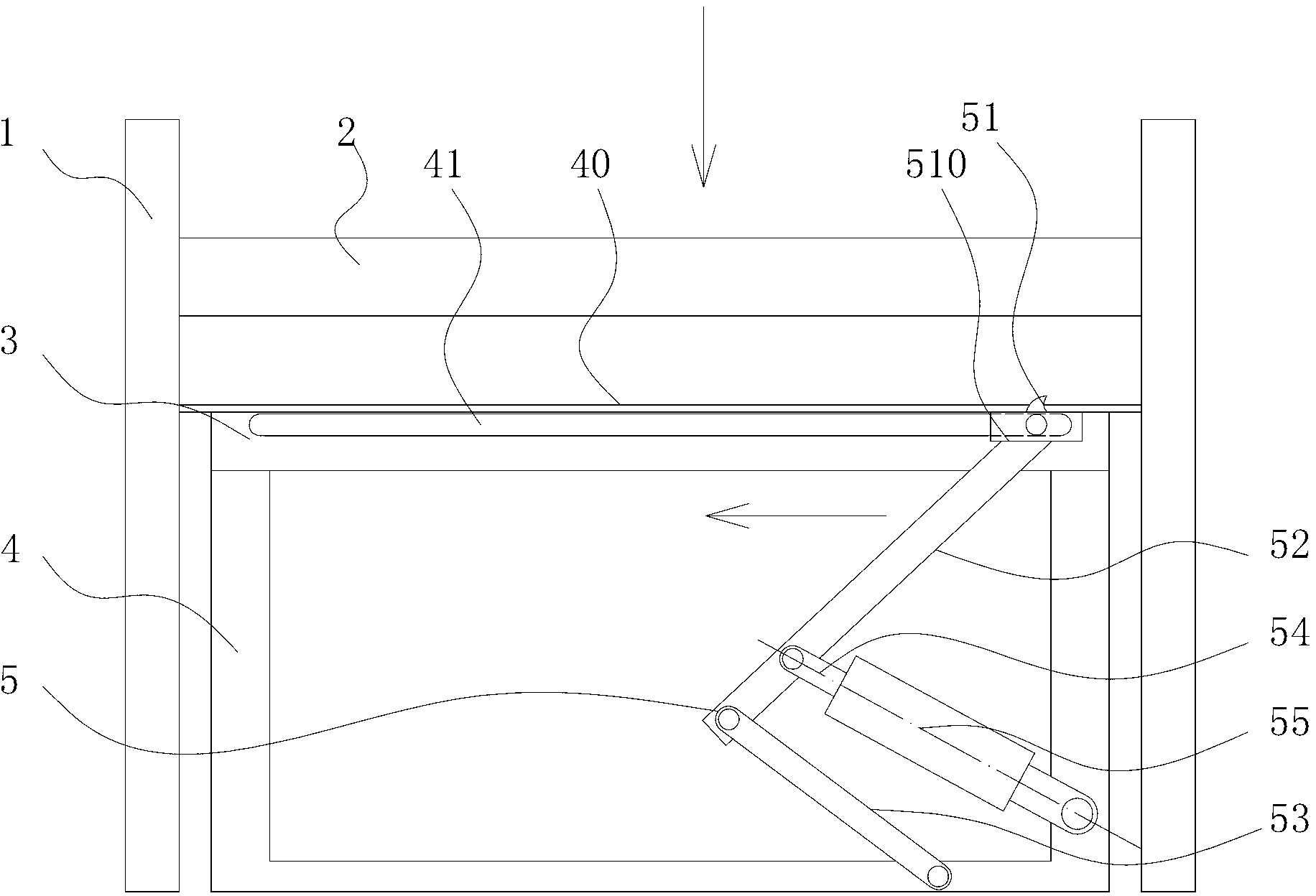

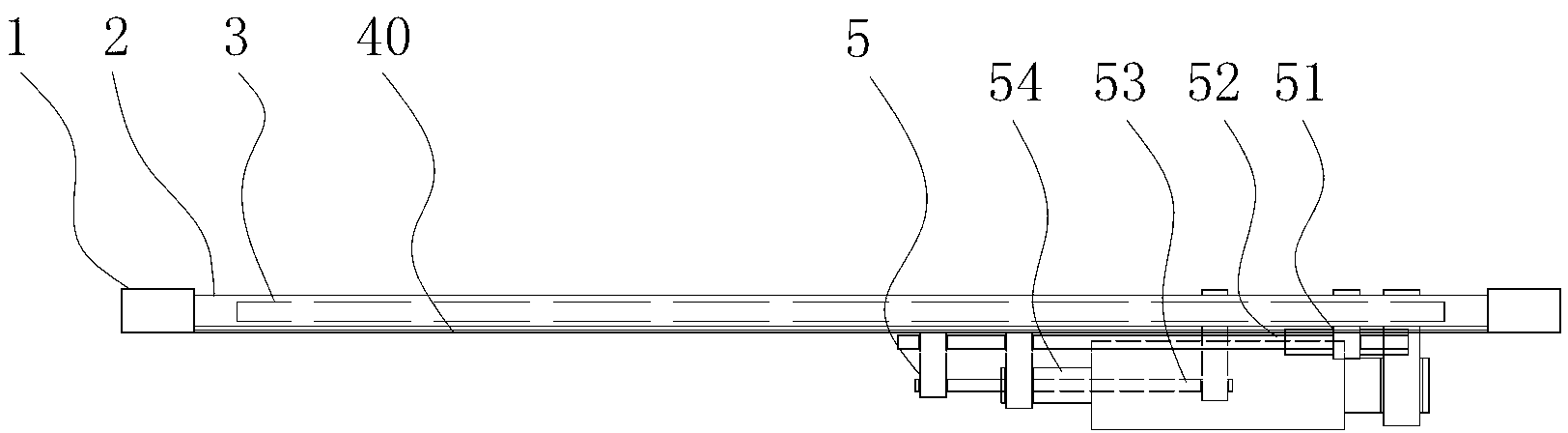

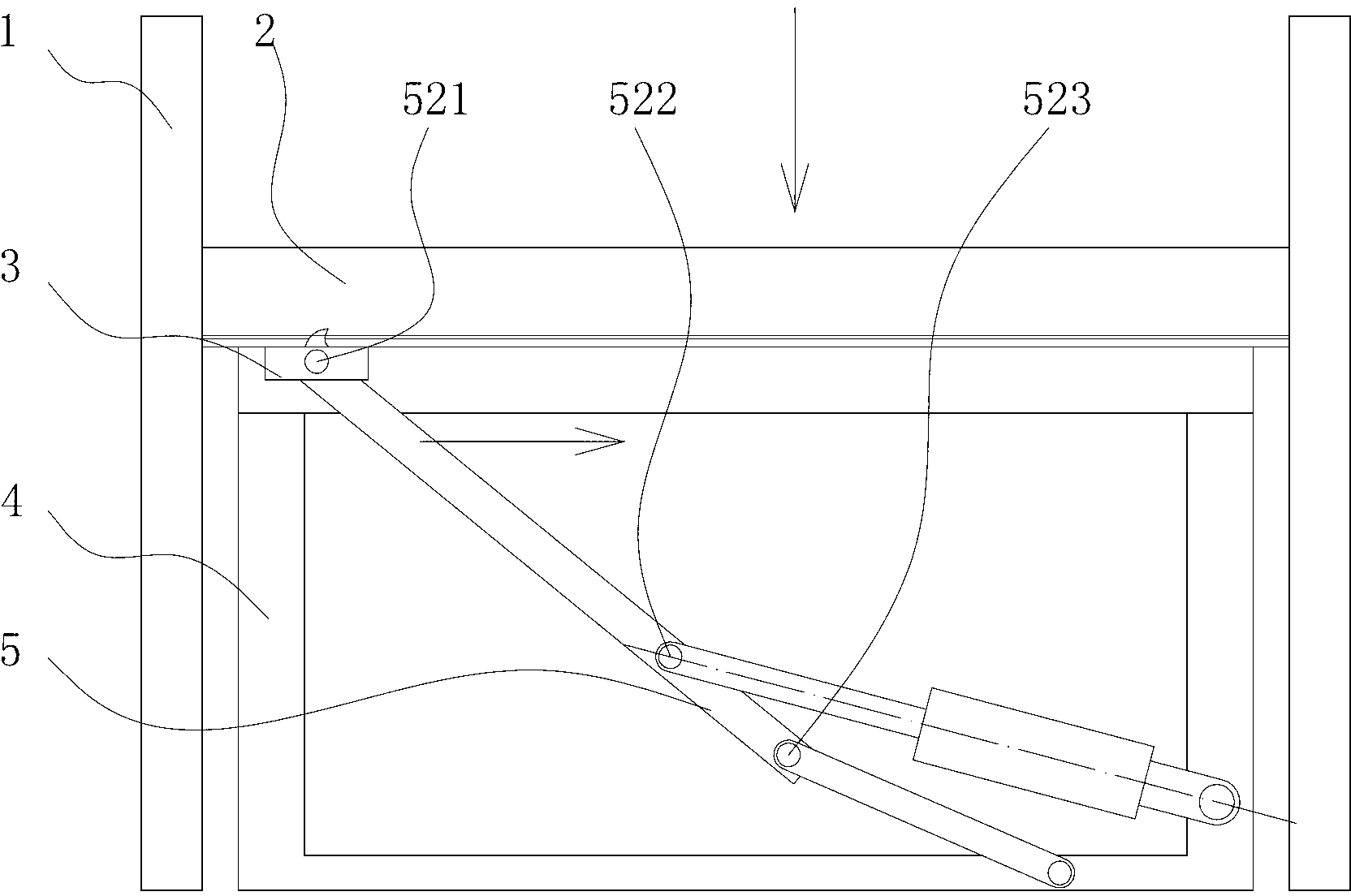

[0016] The present invention as Figure 1-4 As shown, the sheet cutting device includes a pair of outer columns 1, an upper pressing plate 2, a lower pressing plate 3, a bracket 4 and a cutting mechanism 5 connected to the bracket 4, and the upper pressing plate 2 is movably connected to a pair of outer columns 1, it can move up and down between the outer columns 1, and the lower pressing plate 3 is set at the corresponding position below the upper pressing plate 2 (the entrance between the upper pressing plate and the lower pressing plate is the entrance of the sheet) , and fixedly connected to the top of the support 4 (after the sheet enters, the sheet can be effectively clamped by the upper platen and the lower platen), the top of the support 4 is also provided with a guide groove 41;

[0017] The cutting mechanism 5 includes a cutter 51 that is movably connected with the guide groove 41 and can reciprocate in the guide groove 41, a push rod 52, a connecting rod 53, a hydra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap