A package welding method and device

A technology for welding devices and packaging devices, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large temperature gradient, difficulty in finding suitable solder, low efficiency, etc., and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

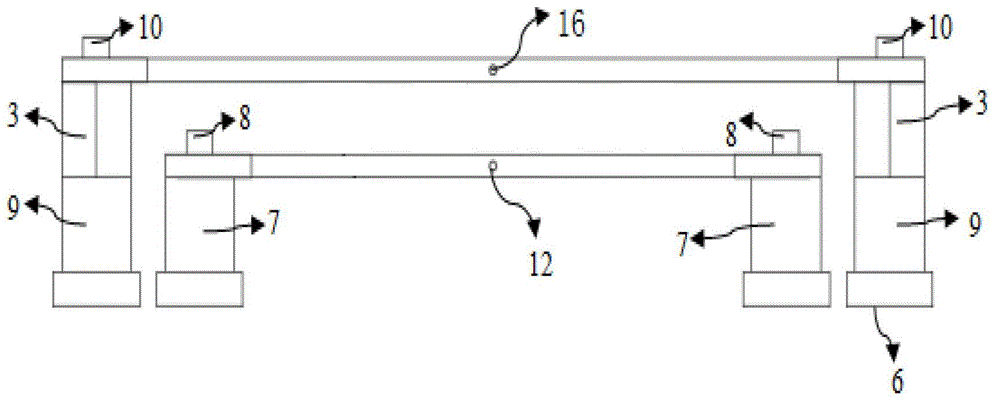

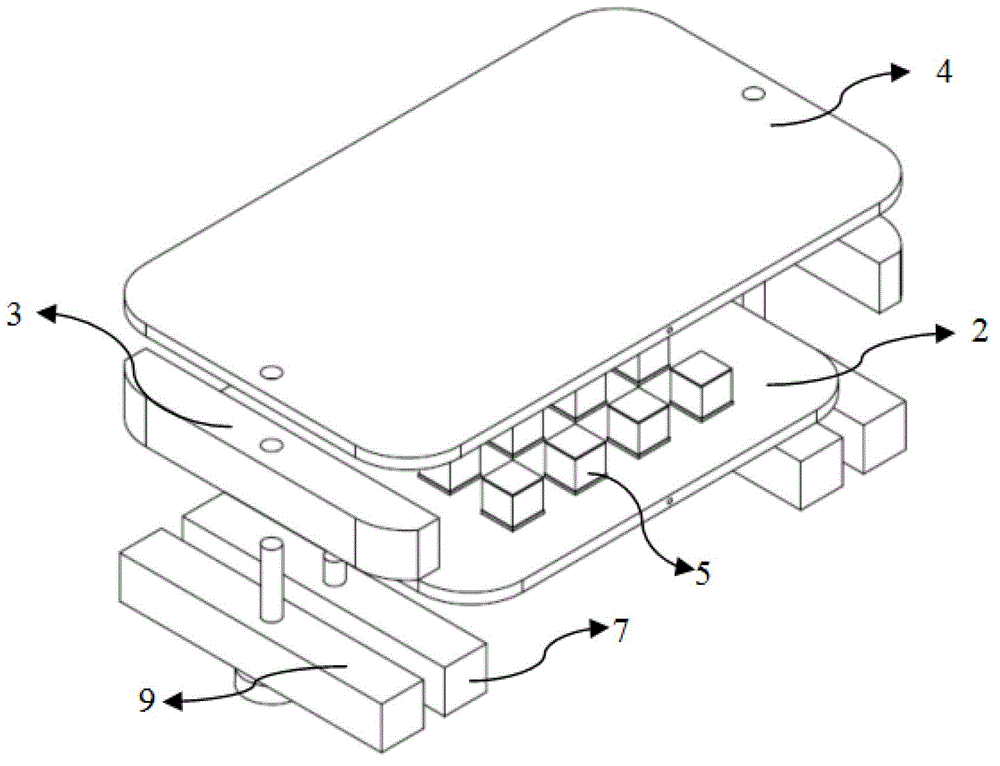

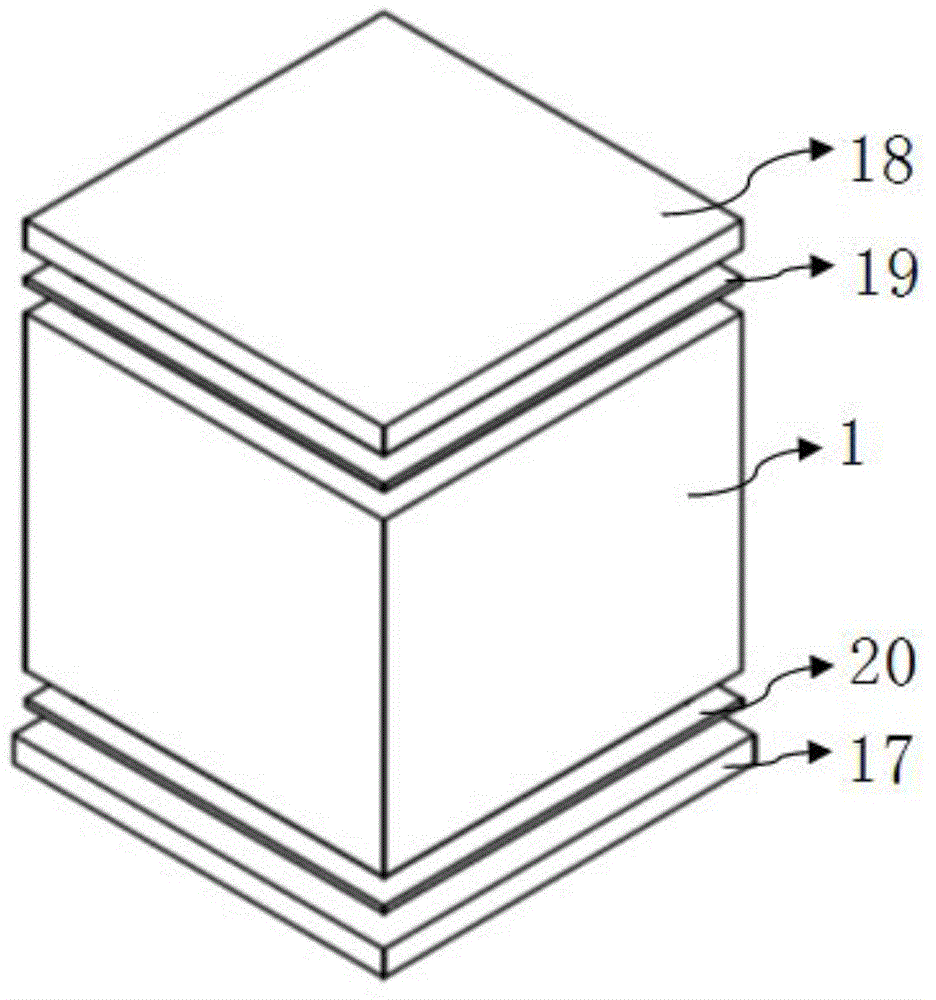

[0044] The present invention adopts the mode that two pairs of electrodes respectively control the upper and lower heating plates, and simultaneously treats the substrate 17 and the cover plate 18 of the packaged device 5 (such as image 3 ) to heat the cover plate solder 19 and the base plate solder 20 to complete the welding of the cover plate 18 , the base plate 17 and the shell 1 . image 3It is a separation diagram of the main components of the present invention, mainly including the metal electrode 9 of the upper heating plate, the metal electrode 7 of the lower heating plate, the lower heating plate 2, the conductive block 3, the upper heating plate 4 and the device 5 to be packaged.

[0045] Metal electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com