Organic glass sealing operation box for chemically polishing glass

A chemical polishing and plexiglass technology, which is applied to manipulators, grinding machine tools, grinding devices, etc., can solve the problems of no gas purification treatment, unsuitable glass chemical polishing, lack of gas purification system, etc., and achieves compact structure and low cost. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention more clear, the specific structure, principle and operation of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

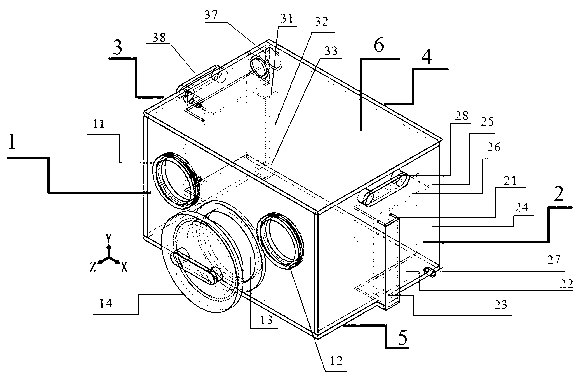

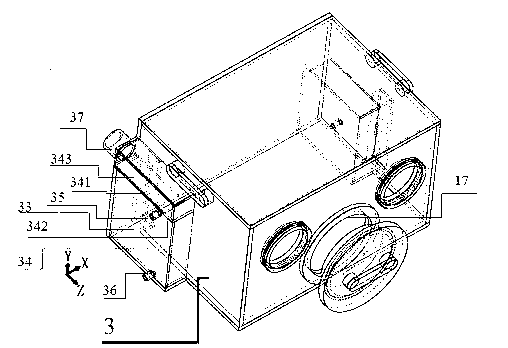

[0021] The present invention proposes a plexiglass sealed operation box for chemical polishing of glass, the structure of which is as follows figure 1 , 2 , 3 shown. Such as figure 1 Shown, this kind sealed operation box has comprised front vertical plate 1, right vertical side plate 2, left vertical side plate 3, rear vertical plate 4, base plate 5, top plate 6.

[0022] Such as figure 1 The top plate 6 is the main observation window.

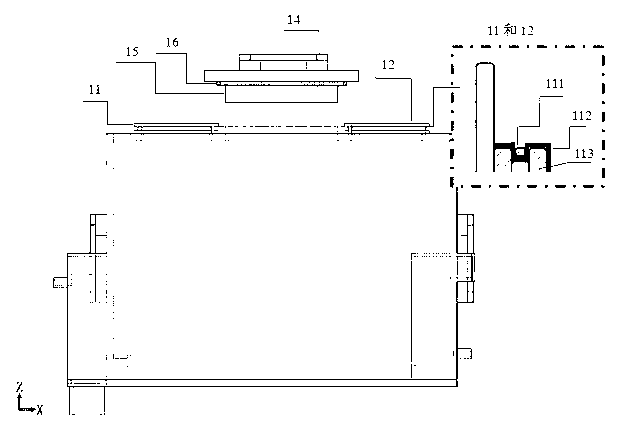

[0023] Such as figure 1 Among them, the front vertical plate 1 includes a left glove interface 11, a right glove interface 12, an operation box door 13 and an operation box door cover 14. Left glove interface 11 and right glove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com