Material extrusion structure and material extrusion method of double-crew extruder

A technology of twin-screw extruder and screw, which is applied in the field of extrusion structure of twin-screw extruder, can solve the problems of screw and barrel scrapping, extruded product surface, black lines, etc., achieve simple structure and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

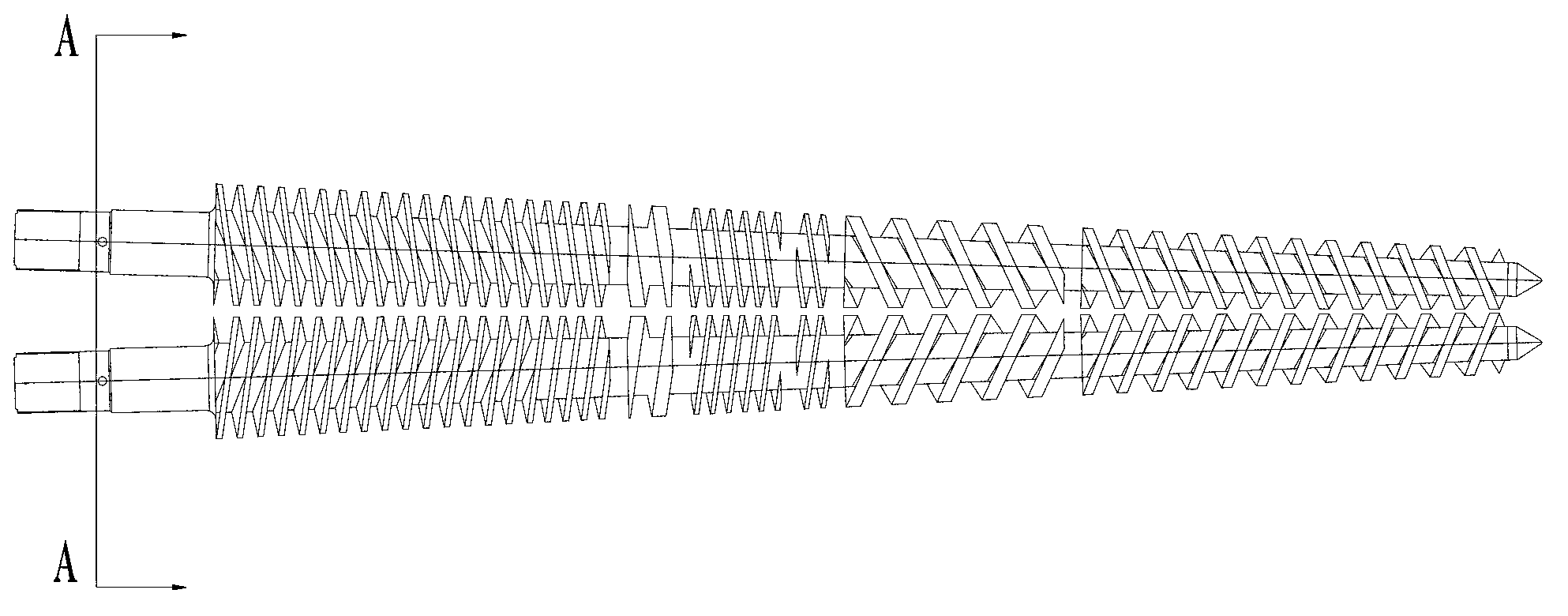

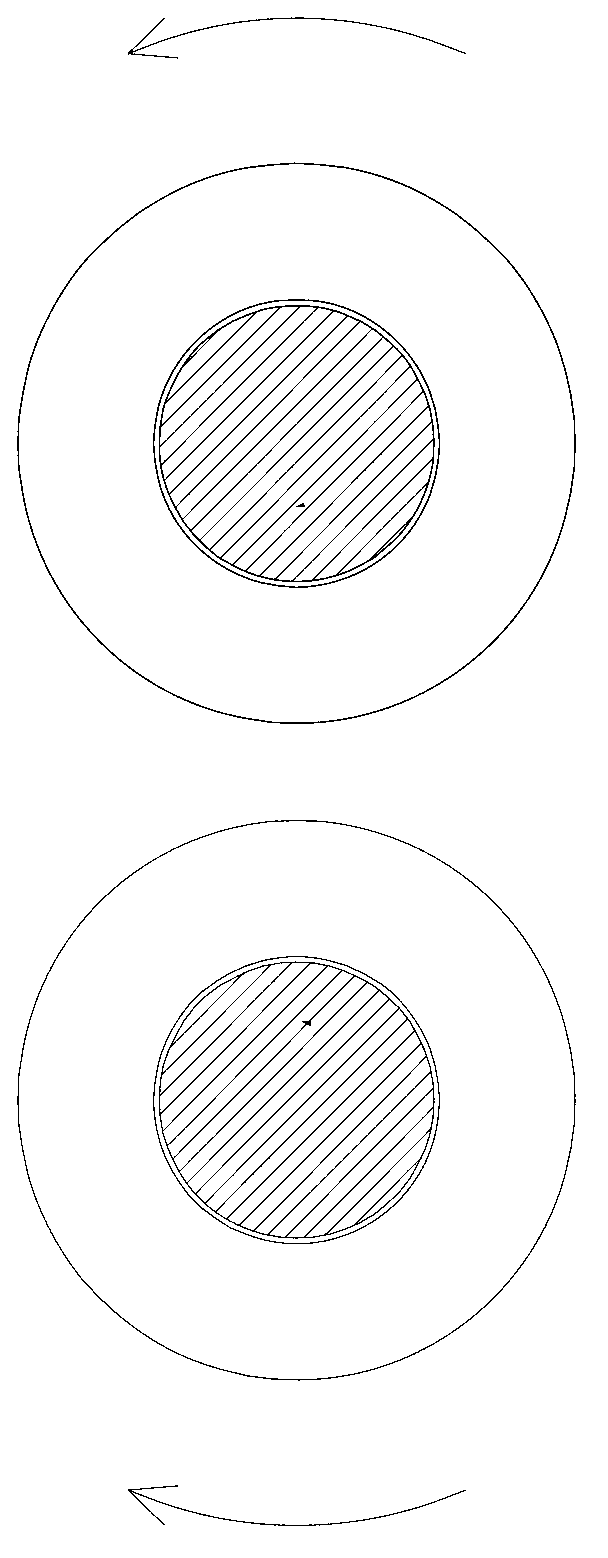

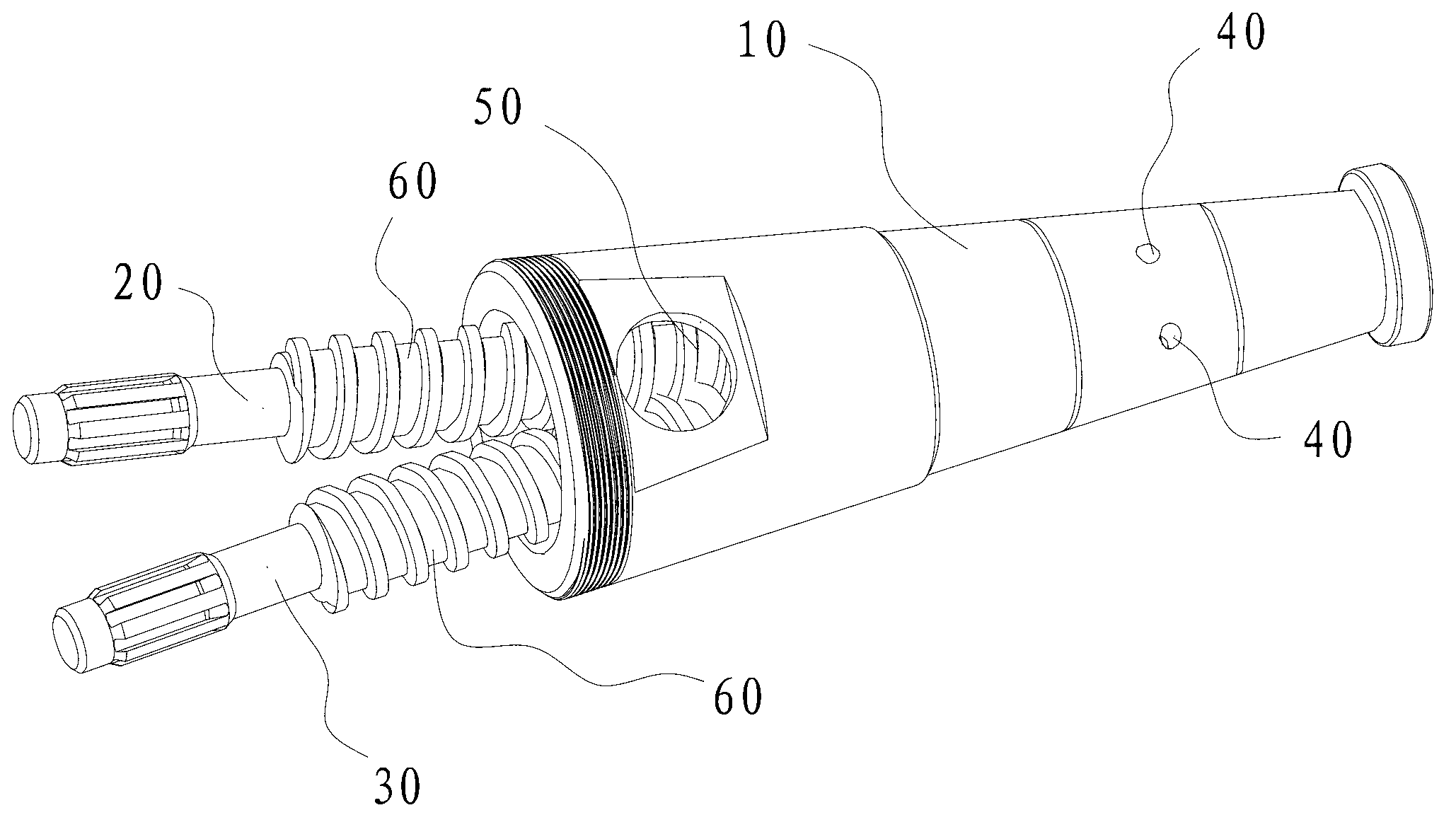

[0025] like image 3 , Figure 4 and Figure 5 As shown, an extruding structure of a twin-screw extruder includes a first screw 20 and a second screw 30 driven by a motor, a barrel body 10, a dehumidification vacuum port 40 and a device on the barrel body 10. The raw material feeding port 50 on the barrel main body 10. The first screw 20 and the second screw 30 are arranged symmetrically, and the surfaces of the first screw 20 and the second screw 30 have screw grooves 60 that can transport materials along the direction from the material feeding port to the dehumidifying vacuum port 40 .

[0026] In this embodiment, the ends of the first screw 20 and the second screw 30 are respectively connected to a distribution gearbox that allows the first screw 20 and the second screw 30 to rotate inwards in different directions inside the barrel body 10 , The distribution gearbox is connected with the output shaft of the motor. The distribution gearbox is directly driven by the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com