Crack lacquer for glass surface

A glass surface and crack paint technology, applied in the field of crack paint, can solve the problems of high requirements for paint film resistance, difficult to effectively ensure long-term adhesion of paint film and substrate, and difficult penetration of paint, etc. Aesthetically resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of glass crack paint primer: Weigh 100 grams of PM-5330KCB (Zhejiang Youqian Special Materials Co., Ltd.), add 1 g of F110 auxiliary (Zhejiang Youqian Special Materials Co., Ltd.), add 5 g of pigment carbon black, uniformly dispersed, Obtain the glass crack primer M used in this example 01 .

[0033] Apply the above glass crack primer M 01 Spray onto the surface of glass plate, bake at 60°C for 4 minutes, then at 900mJ / cm 2 Energy UV curing to give black primer coat M 02 ;

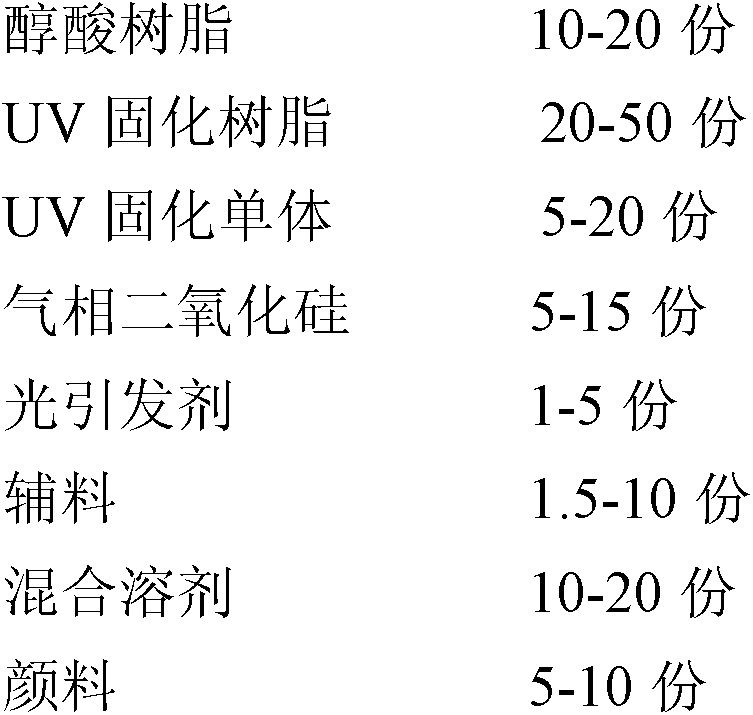

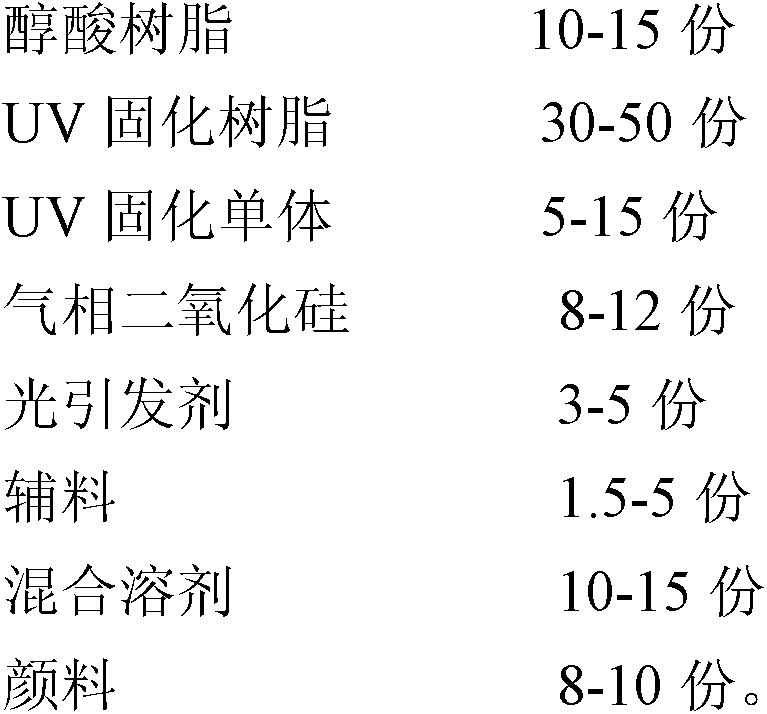

[0034] Preparation of crack paint: 15g of alkyd resin (Jiangsu Sanmu 3430), 45g of urethane acrylate (Taiwan Changxing DR-U025), 8g of trimethylolpropane triacrylate, 8g of trimethylolpropane triacrylate were added successively in a container with a stirrer, and gas phase dioxide Silicon (Beijing Aerospace Saide Company SD-530L) 10g, photoinitiator (BASF Irgavure184) 5g, dispersant (BYK163) 1.5g, anti-settling agent (Deqian Company SD-1) 0.8g, leveling agent (BYK354) 0.5g, 10g of ti...

Embodiment 2

[0038] Preparation of crack paint primer: same as Example 1;

[0039] Preparation of crack paint: the same as Example 1, except that the pigment used is red iron oxide;

[0040] Preparation of crack topcoat: Same as Example 1.

[0041] The spraying method is the same as in Example 1.

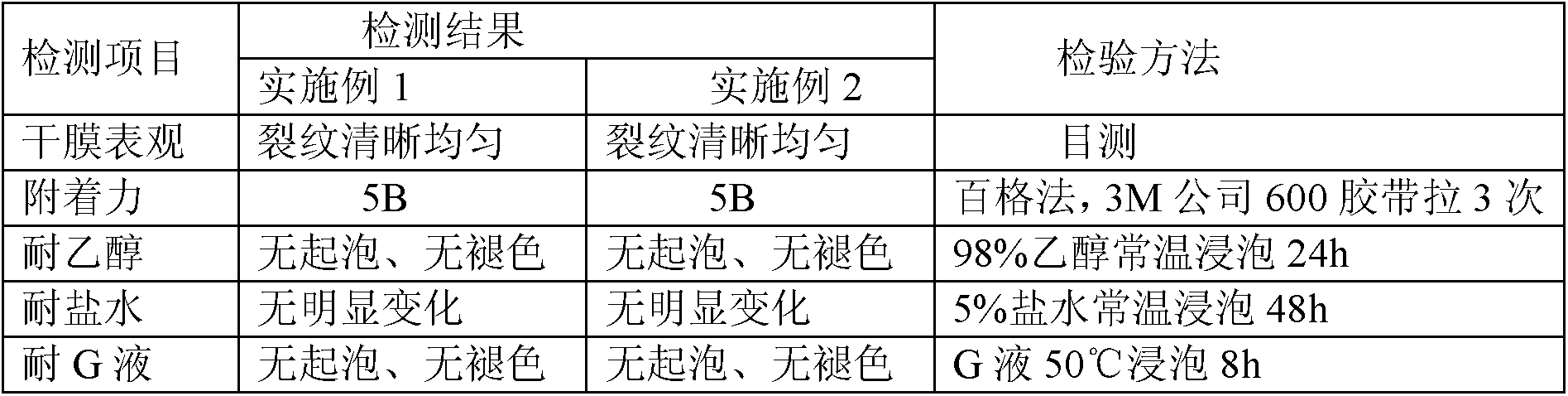

[0042] The performance test results are shown in Table 1:

[0043] Table 1 Performance test results of Examples 1-2

[0044]

Embodiment 3

[0046] Preparation of crack paint primer: same as Example 1;

[0047] Preparation of crack paint:

[0048]Add 10g of alkyd resin (Jiangsu Sanmu 3430), 30g of urethane acrylate (Taiwan Changxing DR-U025), 20g of trimethylolpropane triacrylate, fumed silica (Beijing Aerospace Race German company SD-530L) 15g, photoinitiator (BASF Irgavure184) 3g, dispersant (BYK163) 2.5g, anti-settling agent (Deqian company SD-1) 2.0g, leveling agent (BYK354) 1.0g, titanium dioxide (DuPont R900) 8g, 15g mixed solvent composed of cyclohexanone, acetone, ethyl acetate and butyl acetate in a weight ratio of 6:9:20:6, rotating speed 10M / s, until the dispersion is uniform, filter to obtain the finished cracked paint M 03 .

[0049] The preparation of crack topcoat is the same as that of Example 1; the spraying method is the same as that of Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap