Groove-type embedded part

A kind of embedded parts, groove technology, applied in the direction of construction, building structure, etc., can solve the problems of inconvenient production and implementation, complex production process, high cost, achieve flexible production and processing, increase contact area, reduce material waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

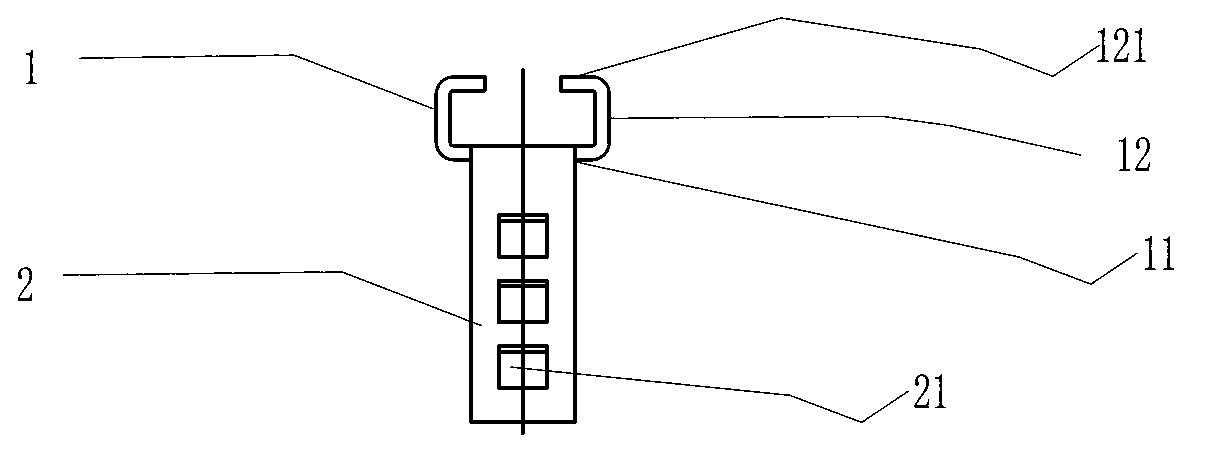

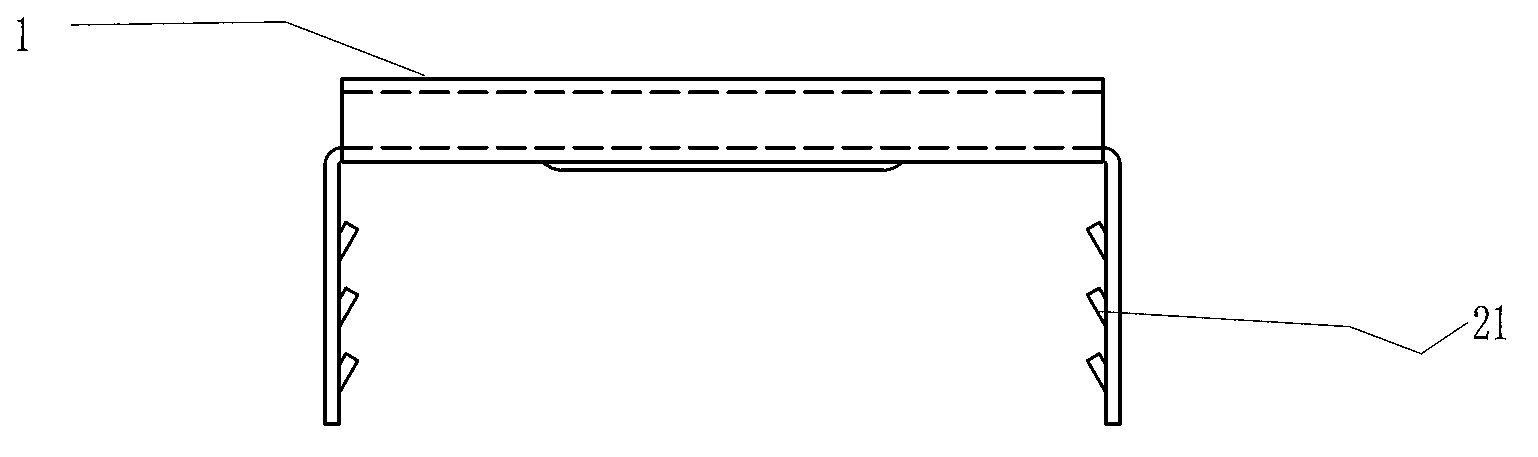

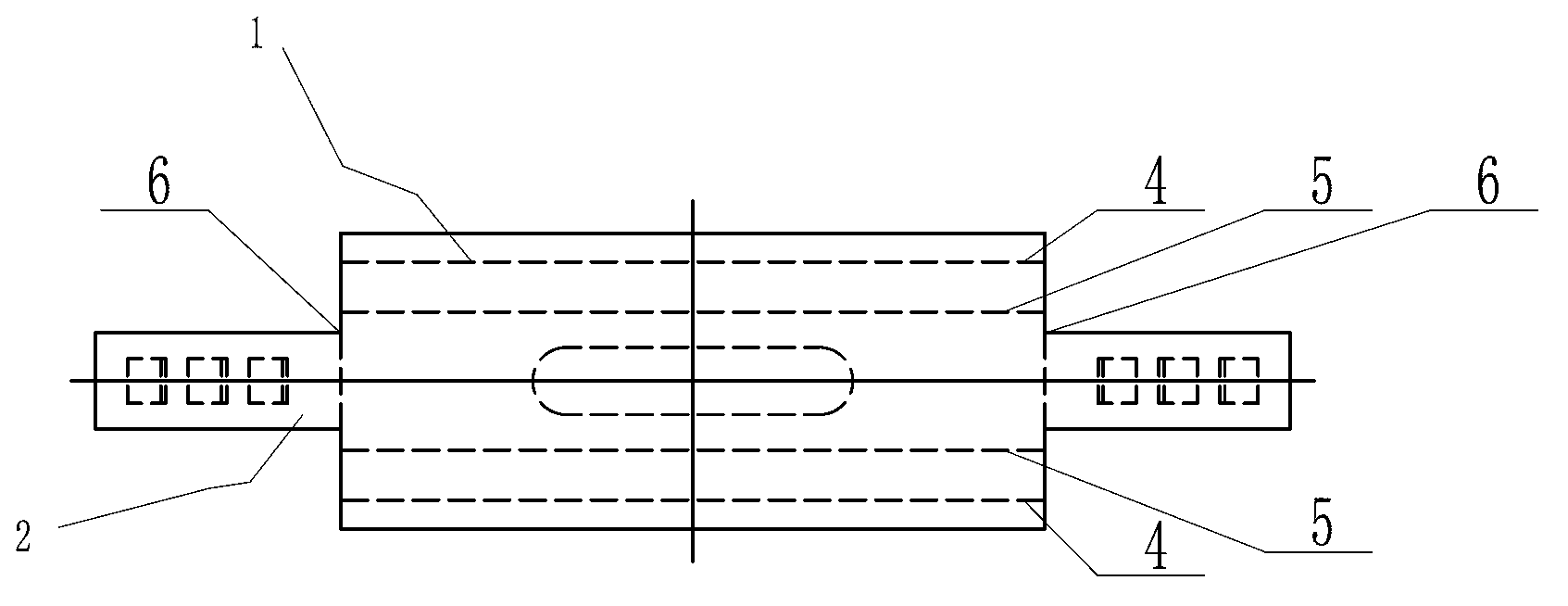

[0036] Such as figure 1 with image 3 As shown, among them, figure 1 It is the front view of the first embodiment of the groove type embedded part of the present invention; figure 2 It is a side view of the first embodiment of the groove-type embedded part of the present invention; image 3 It is an expanded view of the first embodiment of the groove-type embedded part of the present invention.

[0037] The groove-type embedded part of the present invention includes a C-shaped groove 1 and a side wing 2, and the C-shaped groove 1 and the side wing 2 are integrally structured.

[0038] Such as figure 1 As shown, the C-shaped tank 1 includes a base 11 and a side wall 12 . The base 11 is a quadrangle, and its corresponding two sides are connected to the side wings 2 , and the other corresponding sides extend from the side wings 2 in opposite directions to two side walls 12 . The two sidewalls 12 are substantially at a 90-degree angle to the base. Two extension arms 121 ex...

Embodiment 2

[0048] Such as Figure 4 As shown, it is a side view of the groove-type embedded part of the second embodiment of the present invention. Compared with the first embodiment, the present embodiment does not use lugs 21 on the flanks, but uses holes 22 . Holes are opened on the side wings, and the effect of the hole 22 is the same as that of the ear plate 21, which is to increase the contact area with the concrete and improve the strength against pulling out.

Embodiment 3

[0050] Such as Figure 5 As shown, it is a side view of the groove-type embedded part of the third embodiment of the present invention. Compared with the first embodiment and the second embodiment, the side wing 2 is a plane, that is, there is no opening, and there is no ear plate. Another difference is that a support arm 23 is provided on the top of the side wing 2 , and the support arm 23 is basically at an angle of 90 degrees to the side wing 2 , that is to say, it is basically parallel to the base 11 of the C-shaped slot 1 . At this time, the support arm 23 is equivalent to a hook, which increases the contact area with the concrete and improves the strength against pulling out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com