Step-loading plate compression, shearing and testing device

A test device, step-by-step technology, applied in the direction of testing the strength of materials by applying a stable shear force, can solve problems such as failure to achieve shear fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

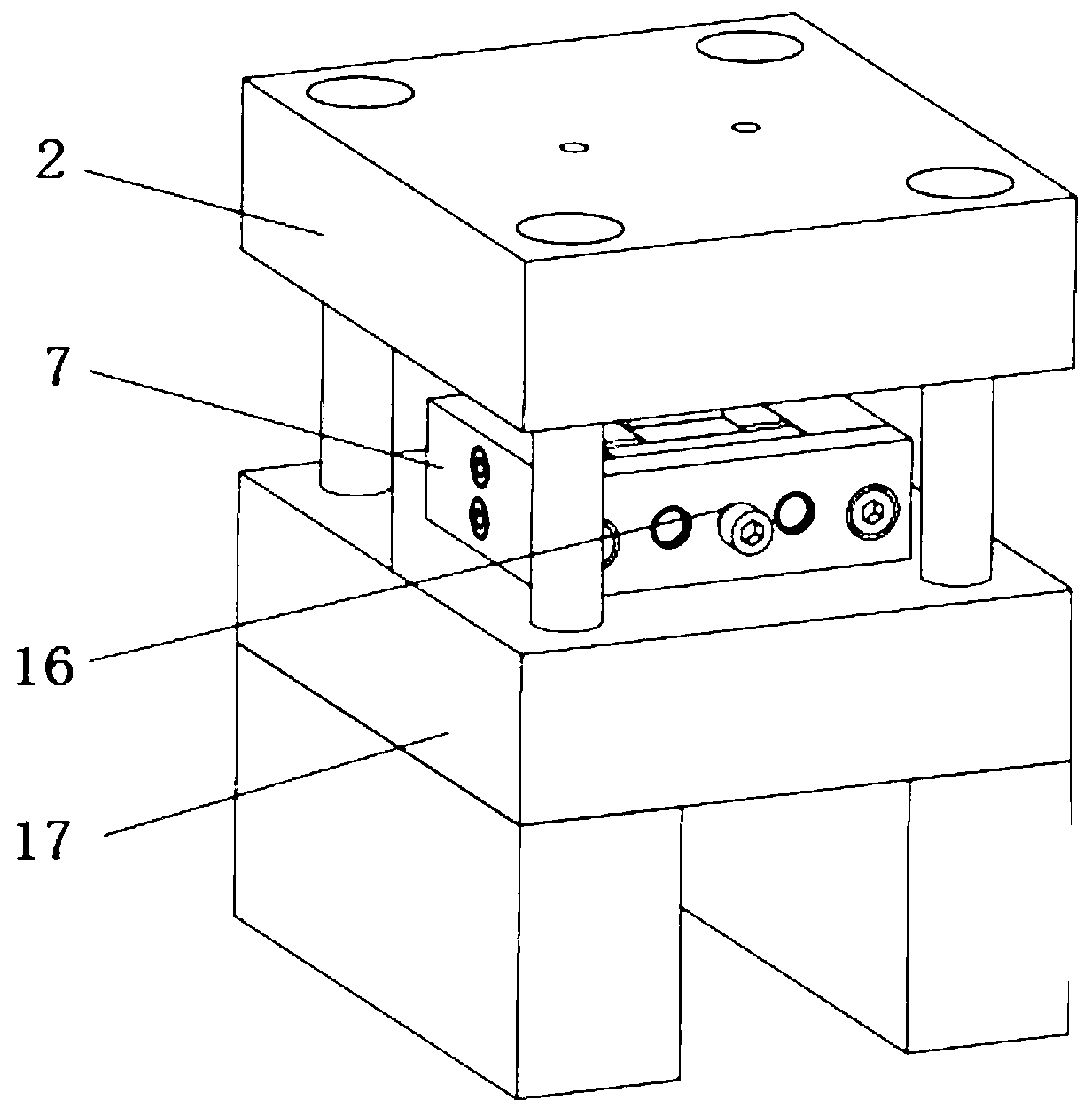

[0032] Such as image 3 As shown, this embodiment includes: an indenter assembly 2, a fixing assembly 7, a sliding locking assembly 16 and a base assembly 17, wherein: the indenter assembly 2 is positioned above the sheet material specimen to be tested for applying pressure to the specimen, The fixed assembly 7 and the sliding locking assembly 16 cooperate to clamp the test piece, and the fixed assembly 7 is fixed on the base assembly 17;

[0033] Such as Figure 5 , Figure 6 , Figure 7 As shown, the sliding locking assembly 16 includes: a front baffle 14, a first backing plate 13, a top block 12 and a pressing piece 15, wherein: the front baffle 14 is connected with the fixing assembly 7, and the top block 12 Located on one side of the test piece and set on the first backing plate 13, the first backing plate 13 and the front baffle 14 are coordinated by the guide mechanism, the pressing part 15 is matched with the front baffle 14, and the pressing part 15 acts on the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com