Preparation method of SiC microwire modified gypsum

A technology of micron wire and gypsum, which is applied in the field of materials and engineering, can solve the problems of complicated preparation process and small increase in the strength of gypsum, and achieve the effect of improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

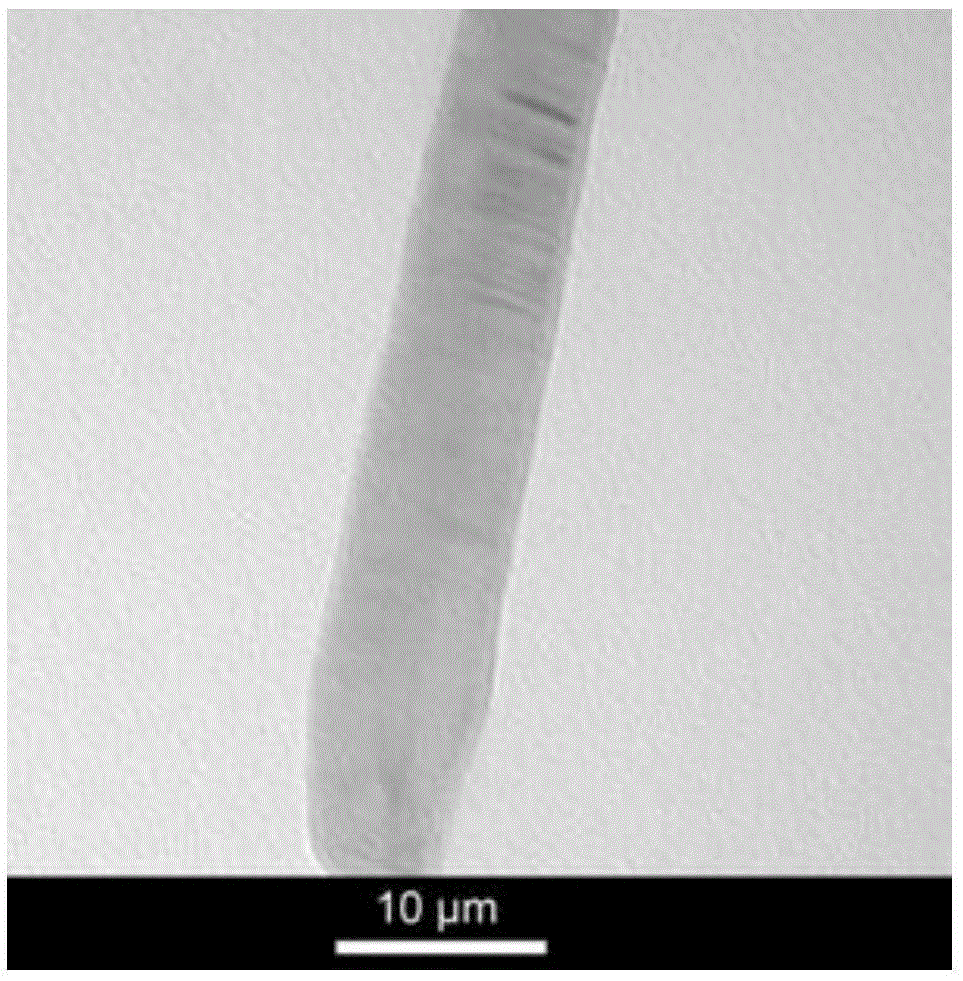

Image

Examples

specific Embodiment 1

[0022] A preparation method of SiC micron wire modified gypsum, comprising the following steps:

[0023] (1) SiC micron wires were soaked in 10% hydrogen peroxide for 96 hours and then dried for later use;

[0024] (2) Add 0.5 parts of SiC microwires obtained in step (1) to 1000 parts of water, and obtain SiC microwire mixture A after ultrasonic dispersion for 10 minutes;

[0025] (3) Add 0.5 parts of SiC microwires obtained in step (1) to 800 parts of ethanol, and obtain SiC microwire mixture B after ultrasonic dispersion for 10 minutes;

[0026] (4) Add 100 parts of gypsum powder to the SiC microwire mixture A obtained in step (2), and stir with a stirrer for 30 minutes to obtain a mixture C;

[0027] (5) Pour half of the mixture C obtained in step (4) into a molding mold, and dry at 20°C for 96 hours to obtain sample D;

[0028] (6), first soak the carbon fiber cloth in the phenolic resin for 12 minutes, then spread the carbon fiber cloth on the upper surface of the sampl...

specific Embodiment 2

[0034] A preparation method of SiC micron wire modified gypsum, comprising the following steps:

[0035] (1) SiC micron wires were soaked in 30% hydrogen peroxide for 24 hours and then dried for later use;

[0036] (2) Add 2 parts of SiC microwires obtained in step (1) to 1000 parts of water, and obtain SiC microwire mixture A after ultrasonic dispersion for 60 minutes;

[0037] (3) Add 2 parts of SiC microwires obtained in step (1) to 800 parts of ethanol, and obtain SiC microwire mixture B after ultrasonic dispersion for 60 minutes;

[0038] (4) Add 900 parts of gypsum powder to the SiC microwire mixture A obtained in step (2), and stir with a stirrer for 60 minutes to obtain a mixture C;

[0039] (5) Pour one-half of the mixture C obtained in step (4) into a molding mold, and dry at 60° C. for 24 hours to obtain sample D;

[0040] (6), after soaking carbon fiber cloth in phenolic resin for 60 minutes, spread the carbon fiber cloth on the upper surface of sample D obtained...

specific Embodiment 3

[0046] A preparation method of SiC micron wire modified gypsum, comprising the following steps:

[0047] (1) SiC micron wires were soaked in 20% hydrogen peroxide for 48 hours and then dried for later use;

[0048] (2) Add 1 part of SiC microwire obtained in step (1) to 1000 parts of water, and obtain SiC microwire mixture A after ultrasonic dispersion for 30 minutes;

[0049] (3) Add 1 part of SiC microwire obtained in step (1) to 800 parts of ethanol, and obtain SiC microwire mixture B after ultrasonic dispersion for 30 minutes;

[0050] (4) Add 500 parts of gypsum powder to the SiC microwire mixture A obtained in step (2), and stir with a stirrer for 45 minutes to obtain a mixture C;

[0051] (5) Pour half of the mixture C obtained in step (4) into a molding mold, and dry at 40° C. for 48 hours to obtain sample D;

[0052] (6), after soaking carbon fiber cloth in phenolic resin for 40 minutes, spread the carbon fiber cloth on the upper surface of sample D obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com