Proton exchange membrane conductivity characterization device

A proton exchange membrane, conductivity characterization technology, applied in the direction of material impedance, material resistance, etc., can solve problems such as inability to characterize, and achieve the effects of reducing test errors, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

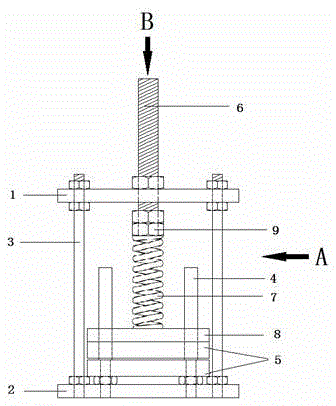

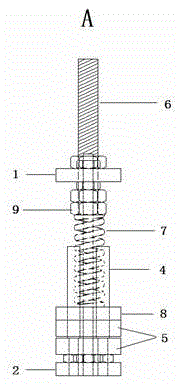

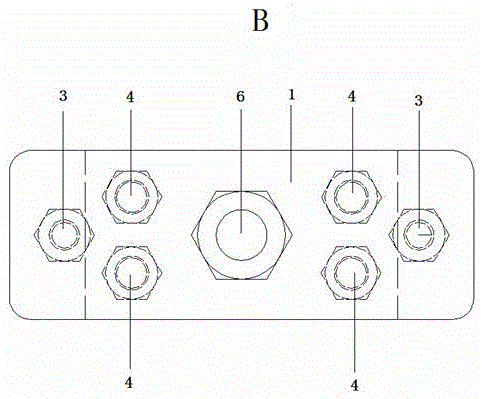

[0027] see Figure 1~Figure 3 , a proton exchange membrane conductivity characterization device, combined with an electrochemical workstation or an AC impedance tester to quickly measure the conductivity of the proton exchange membrane, including a fixed frame, a membrane clamp 5 and a pressurizing device; the fixed frame is composed of an upper base plate 1. A lower base plate 2 and two support screws 3 are assembled to form an overhead installation and unloading space for the film clamp 5 between the left and right support screws 3 and between the upper base plate 1 and the lower base plate 2. Each support screw The bottom end and the top end of 3 are vertically fixedly assembled and connected with the lower base plate 2 and the upper base plate 1 respectively, the upper base plate 1 and the lower base plate 2 are arranged in parallel, and there are at least two film clamp fixing rods 4 vertically fixed and installed on the two supports on the lower base plate 2 Between the ...

Embodiment 2

[0043] This example is basically the same as Implementation 1, the special features are:

[0044] In the present embodiment, the specific test steps of the conductivity of the proton exchange membrane are as follows:

[0045] (1) Same as Embodiment 1.

[0046] (2) Same as Embodiment 1.

[0047] (3) Production of variable components:

[0048] Membrane fixture 5: Two PTFE plates of 74mm*40mm*10mm (length, width and height). There is a 10mm*10mm*1mm (length, width and depth) electrode groove in the middle of the PTFE plate, and two electrodes are drawn from both sides. 17.5mm*0.8mm*1mm wire slot. There are screw holes with a diameter of 6.5mm for fixing on the four corners of the polytetrafluoroethylene plate placed below, and there are screw holes with a diameter of 8.5mm for fixing at the four corners of the polytetrafluoroethylene plate placed above.

[0049] Electrodes: Two 10mm*10mm*1mm square platinum electrodes, both of which are led out by platinum wires with a diamet...

Embodiment 3

[0051] This example is basically the same as the previous implementation, except that:

[0052] In the present embodiment, the specific test steps of the conductivity of the proton exchange membrane are as follows:

[0053] (1) Same as the previous embodiment.

[0054] (2) Same as the previous embodiment.

[0055] (3) Production of variable components:

[0056] Membrane fixture 5: Two 74mm*40mm*10mm (length, width and height) PTFE plates, the upper and lower PTFE plates have electrode grooves of 40mm*0.8mm*1mm, two upper and lower plates, and the upper and lower plates of the membrane fixture have The distance between adjacent electrode grooves is 2 mm after the groove surfaces overlap. There are screw holes with a diameter of 6.5mm for fixing on the four corners of the polytetrafluoroethylene plate placed below, and there are screw holes with a diameter of 8.5mm for fixing at the four corners of the polytetrafluoroethylene plate placed above.

[0057] Electrodes: four cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com