Rapid positioning method for breakover point of insulation resistance of bifilar parallel wound coil

A technology of insulation resistance and positioning method, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as hidden dangers of production efficiency and product reliability, short circuit of two sets of coils, conduction of insulation resistance, etc., to achieve high efficiency, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below by specific embodiment:

[0017] The present invention adopts the commonly used testing instrument for insulation resistance, takes the double-wire parallel winding coil with insulation resistance conduction as a sample, and then divides it into "two steps" to decompose and locate the conduction point of the insulation resistance of the enameled wire. Through the two-step test method of "shaking while retreating" and "shaking while sliding", quickly and accurately locate the conduction point of the insulation resistance of the double-wire and winding coil.

[0018] Specific process

[0019] step 1

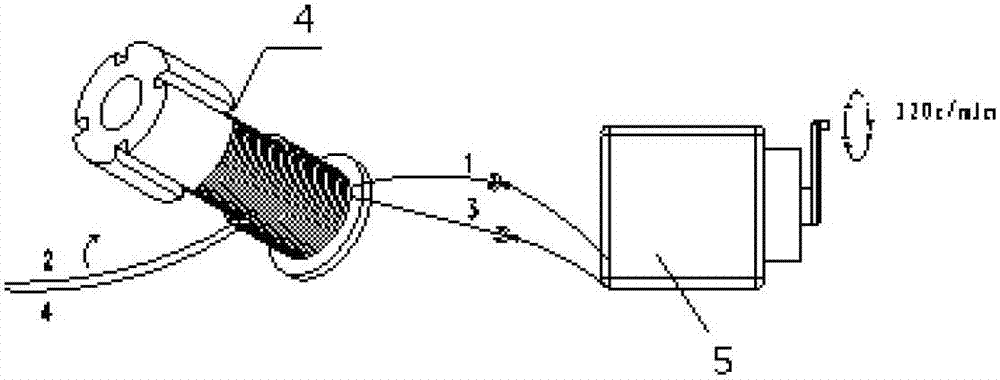

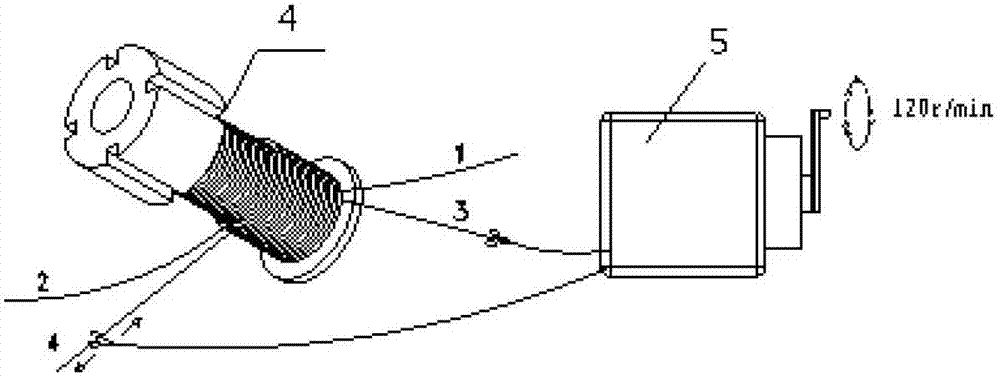

[0020] see figure 1 , Use the method of "shaking while retreating" to decompose the coil. "Shaking" refers to shaking the megohmmeter at a speed of 120r / min to test the insulation resistance, and "retreating" refers to withdrawing the coil. The detailed process is that the double-wire winding coil has four lead ends, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com