Construction method for AC (alternating current) electromagnetic levitation spindle controller

A technology of magnetic levitation electric spindle and construction method, which is applied in the direction of manufacturing tools, adaptive control, general control system, etc., can solve the problem that the number of hidden layers, the number of hidden layer nodes and the initial weight are difficult to determine, the structure is complex, and the influence of calculation speed and Results and other issues, achieve good anti-load disturbance ability, good robust control system, and ensure the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

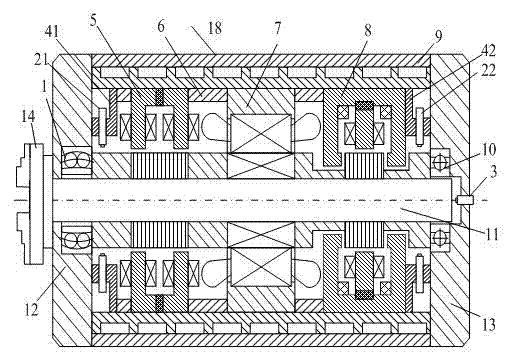

[0027] Such as figure 1 , the AC magnetic levitation electric spindle 18 is composed of a two-degree-of-freedom AC hybrid magnetic bearing 5, a three-degree-of-freedom AC-DC hybrid magnetic bearing 8 and a high-speed motor 7, and two AC hybrid magnetic bearings (two-degree-of-freedom AC hybrid magnetic bearing 5 and three-degree-of-freedom AC-DC hybrid magnetic bearing 8) and high-speed motor 7 are installed in the sleeve 9, and the inner diameter of the sleeve 9 is provided with a threaded coolant channel; 2 AC hybrid magnetic bearings (two-degree-of-freedom AC hybrid magnetic bearing 5 and three The degree of freedom AC-DC hybrid magnetic bearing 8 and the high-speed motor 7 share a rotating shaft 11, and the two ends of the rotating shaft 11 are respectively supported by the radial-axial auxiliary bearing 1 and the radial auxiliary bearing 10. The radial-axial auxiliary bearing 1 adopts double row The angular contact ball bearing is fixed on the front end cover 12; the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com