A Welding Fatigue Analysis Method Based on Rough Set Theory

A rough set theory and welding fatigue technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of reducing the accuracy of fatigue life of welded structures, lack of correlation, etc., and achieve fatigue analysis and analysis of welded structures Prediction is accurate and reliable, and the effect of reducing calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

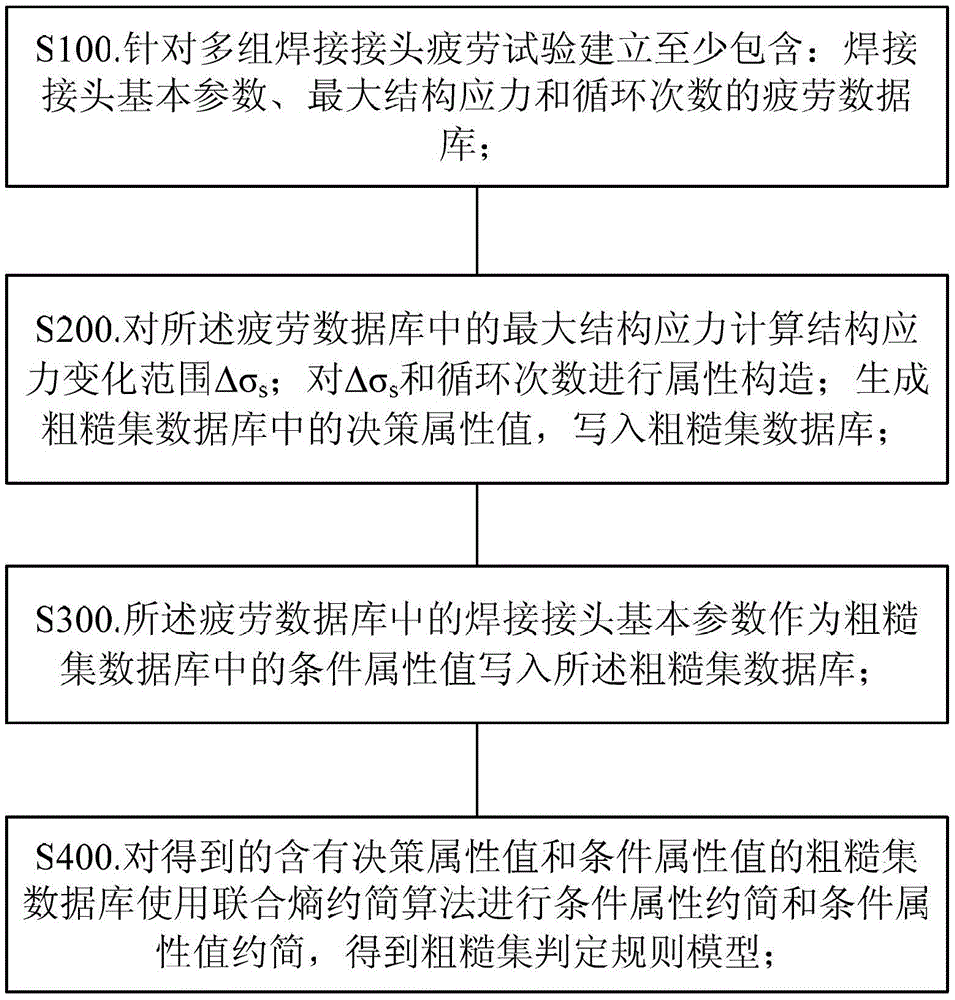

[0049] Such as figure 1 Shown: A welding fatigue analysis method based on rough set theory, which mainly includes the following steps:

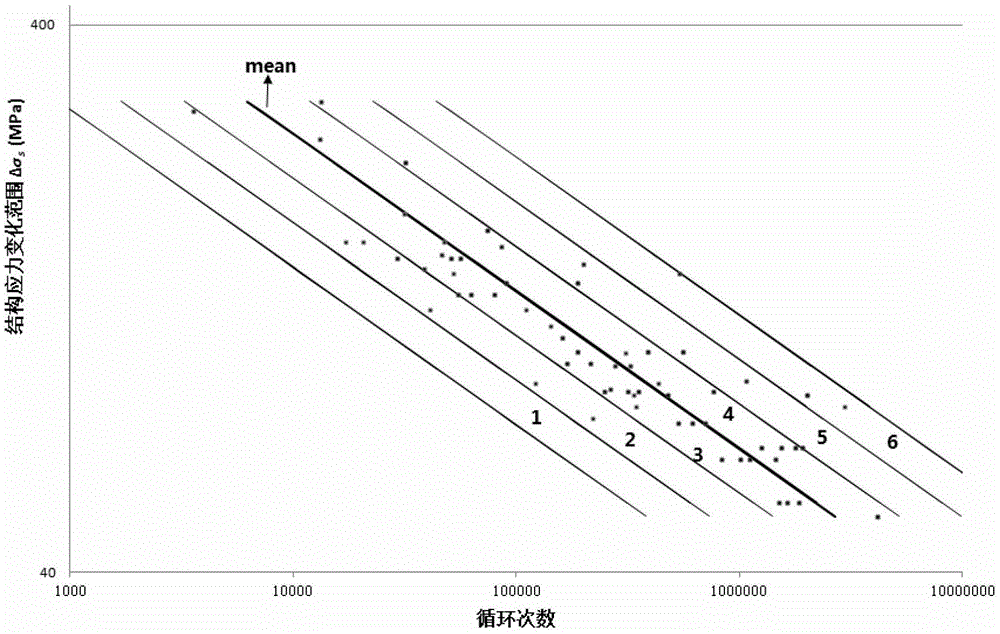

[0050] S100. Establish a fatigue database including at least basic parameters of welded joints, maximum structural stress and cycle times for multiple sets of welded joint fatigue tests:

[0051]

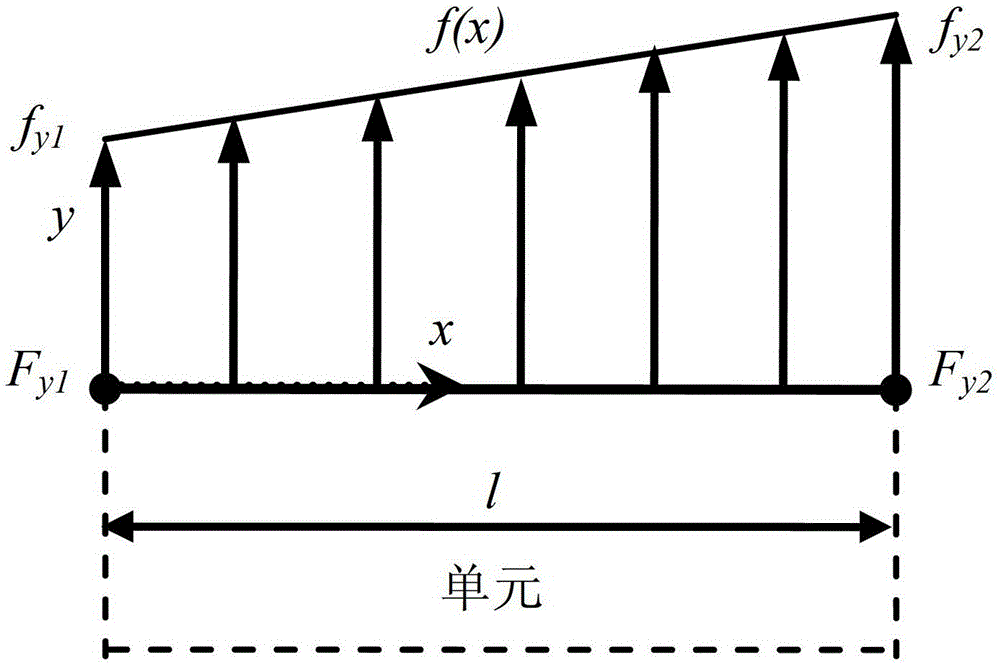

[0052] The basic parameters of the welded joint mainly include: material name, joint type, load type, stress ratio, weldment thickness, weld leg length, welding method, yield strength, tensile strength, bending stress ratio and other parameters. And, the load type, stress ratio, bending stress ratio and maximum structural stress ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com