Carbon brush for electric tool

A technology for electric tools and carbon brushes, applied in the field of carbon brushes for electric tools, can solve the problems of easy falling off and shortening the service life of carbon brushes, and achieve the effects of not easy falling off, huge vibration and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

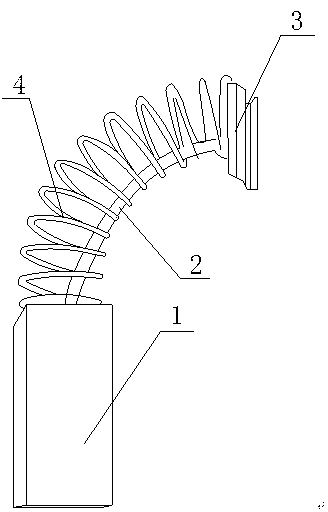

[0011] Such as figure 1 As shown, the carbon brush for electric tools of the present invention includes a carbon brush body 1, the shape of the carbon brush body 1 is a cuboid or a cube, and a wire 2 is drawn out of the carbon brush body 1, the wire 2 is a copper core flexible wire, and the end of the wire 2 Connected with the copper sheet 3, the outer periphery of the wire 2 is covered with a spring 4, one end of the spring 4 is fixed on the carbon brush body 1, and the other end of the spring 4 is fixed on the copper sheet 3.

[0012] The carbon brush body 1 is stuck on the metal bracket, and the outer periphery of the wire 2 is covered with a spring 4. The spring 4 presses it tightly on the rotating shaft. When the machine is working, it will generate huge vibrations, and it is not easy to fall off, and the service life is long.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com