Split piano type shielding device on end part of steam-turbine generator

A technology of turbogenerator and shielding device, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor heat dissipation effect, inability to effectively reduce its own temperature, and large eddy current loss, etc., to reduce the temperature of metal shielding, Ease of realization and application, and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

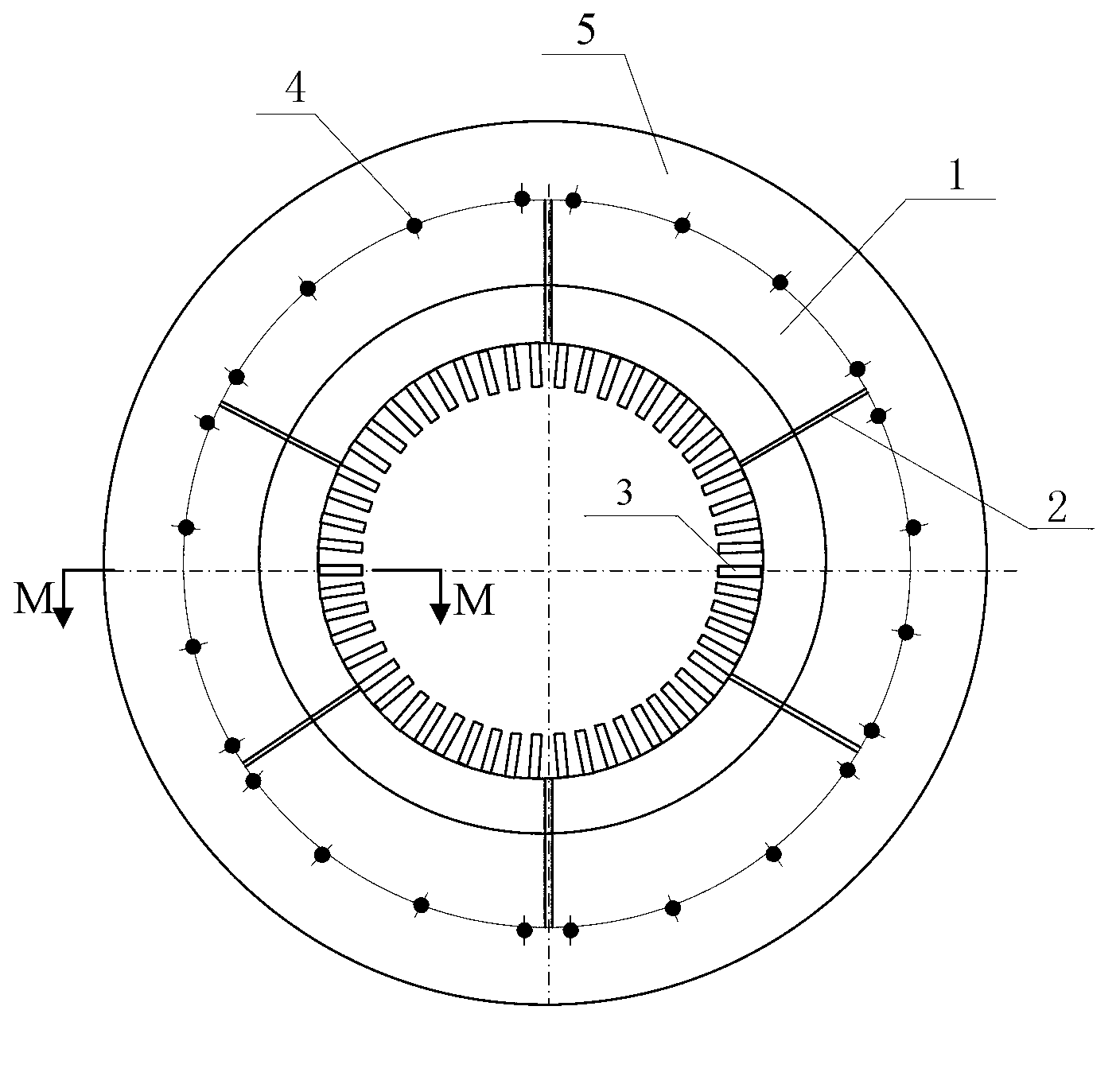

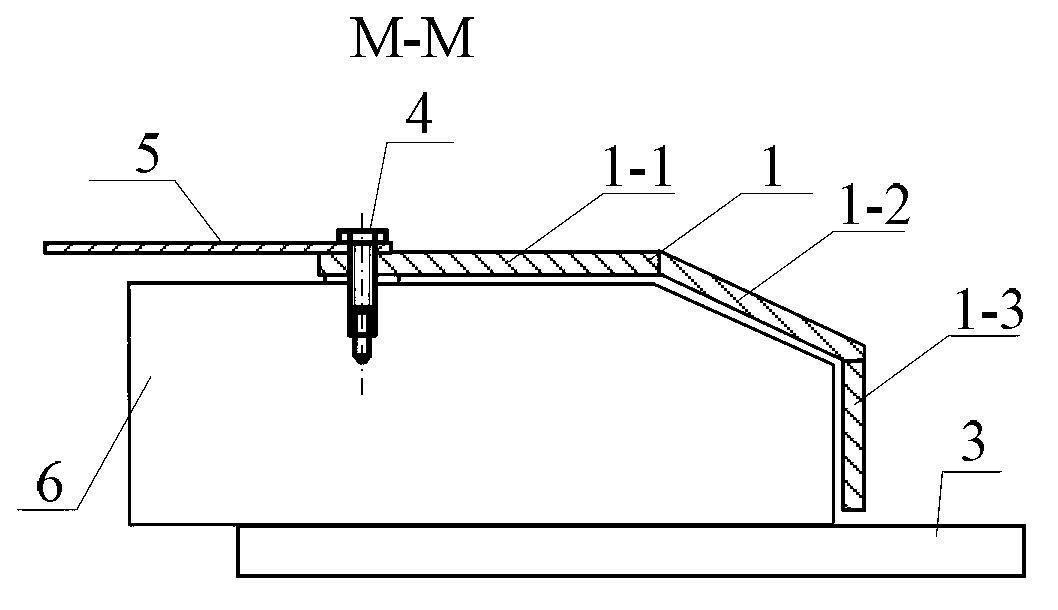

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a split-lobe piano shielding device at the end of a turbogenerator in this embodiment includes a ring windshield 5, a pressure ring 6 and a pressure finger 3, the pressure ring 6 is pressed on the pressure finger 3, And the pressure ring 6 is located on the end of the turbogenerator, and the device also includes at least two shielding plates 1, each of which is a three-section bending plate, and the first section 1-1 of the shielding plate 1 Set horizontally, the angle between the second section 1-2 of the shielding plate 1 and the first section 1-1 is an obtuse angle, the third section 1-3 of the shielding plate 1 is vertically set, the second section 1 of the shielding plate 1 The included angle between -2 and the third section 1-3 is an obtuse angle, each of the shielding plates 1 is a piano structure, and at least two shielding plates 1 are arranged along the circumferential ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To describe this embodiment, the gap 2 left between every two adjacent shielding plates 1 in this embodiment is 8 mm to 10 mm. Such setting can hinder the eddy current of the metal shield, reduce loss and facilitate heat dissipation. Others are the same as in the first embodiment.

specific Embodiment approach 3

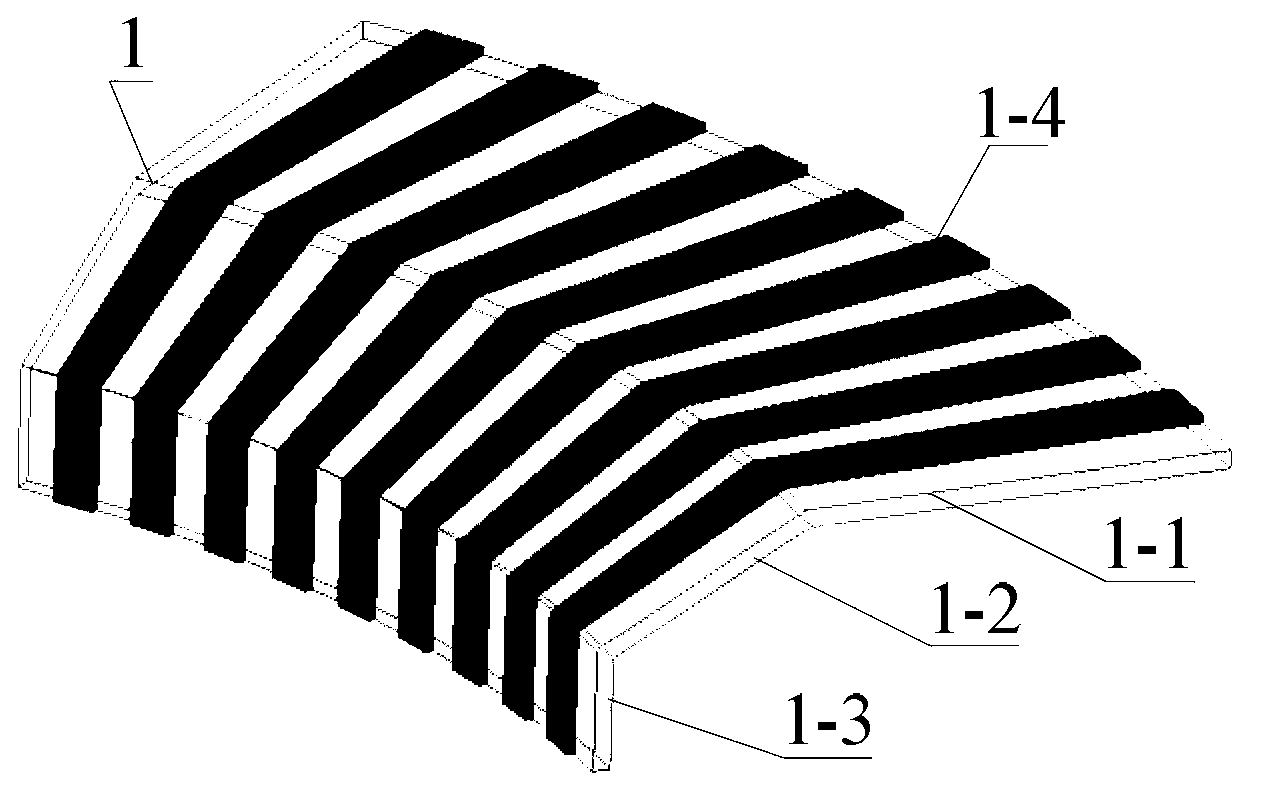

[0013] Specific implementation mode three: combination image 3 To illustrate this embodiment, a plurality of first protrusions 1-4 are provided on the front surfaces of the first segment 1-1, the second segment 1-2 and the third segment 1-3 of each shielding plate 1 in this embodiment, One end of the first protrusion 1-4 is arranged on the inner edge of the third section 1-3, and the other end of the first protrusion 1-4 is arranged on the outer edge of the first section 1-1. Such setting greatly enhances the self-radiation effect and reduces the self-temperature of the metal shield. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com