High-speed circular sawing machine

A circular sawing machine, high-speed technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment and other directions, can solve the problems of insufficient clamping mechanism feeding mechanism, difficult high-speed precision cutting, slow cutting speed, etc. Achieve the effect of simple structure, labor saving and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

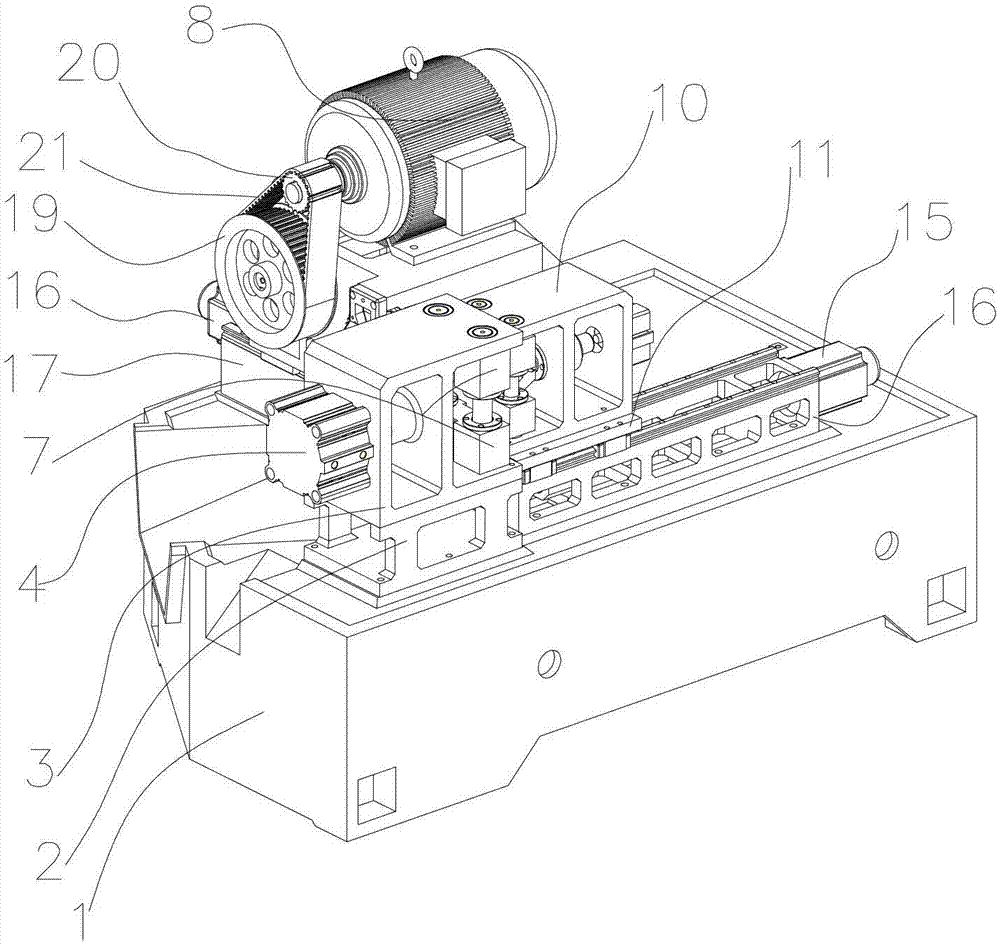

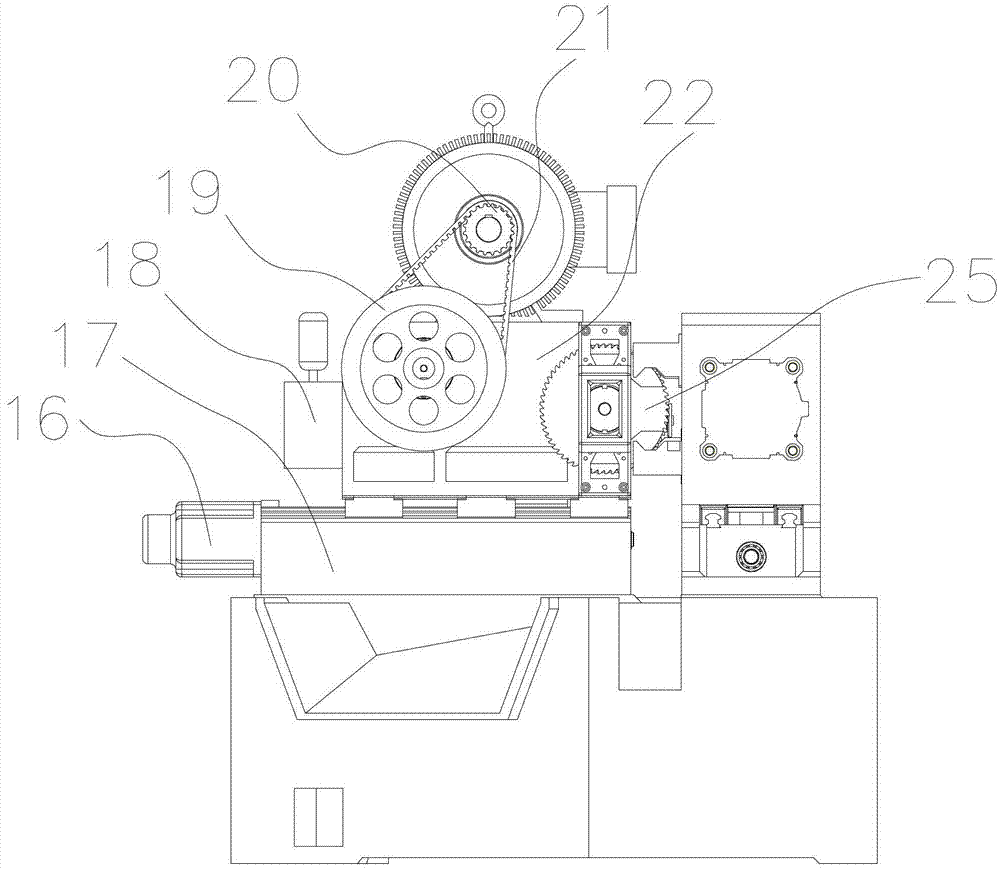

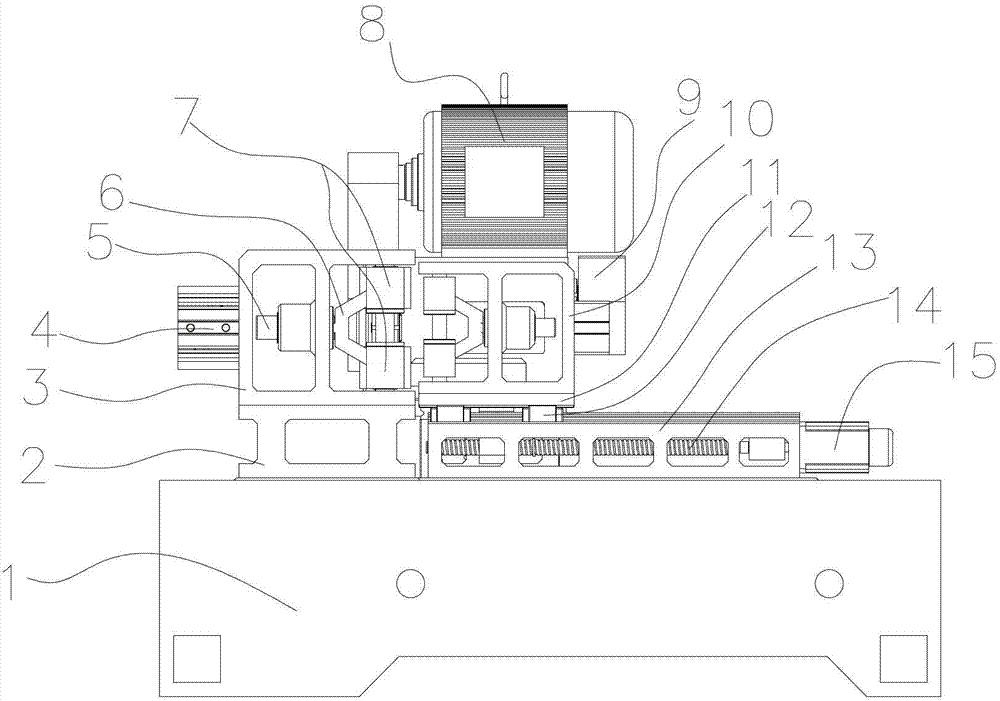

[0020] Referring to the accompanying drawings: a high-speed circular saw machine includes a bed, one end of the bed is provided with a top double-clamp clamping mechanism A and a parallel cutting mechanism, and the other end is provided with a feeding mechanism. Mechanism A includes a front clamping base installed on the bed. A clamping mechanism B with an opening at one end is provided on the front clamping base. One side of the clamping mechanism B is fixedly connected with a cylinder; the parallel cutting mechanism includes There is a cutting base arranged on the bed, and a linear guide rail is provided on the cutting base. A feed motor B is installed on one side of the cutting base, and a screw B is installed on the output end of the feed motor B. The linear guide rail A linear guide rail slider is slidably installed on the screw rod B, and a screw nut fixing block is installed on the screw rod B. The linear guide rail slider is driven by the screw rod B, and a spindle box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com