Packing container

A technology for packaging containers and thermoplastic materials, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of raw material waste, energy waste, etc., and achieve the effects of reduced necking, firm combination, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

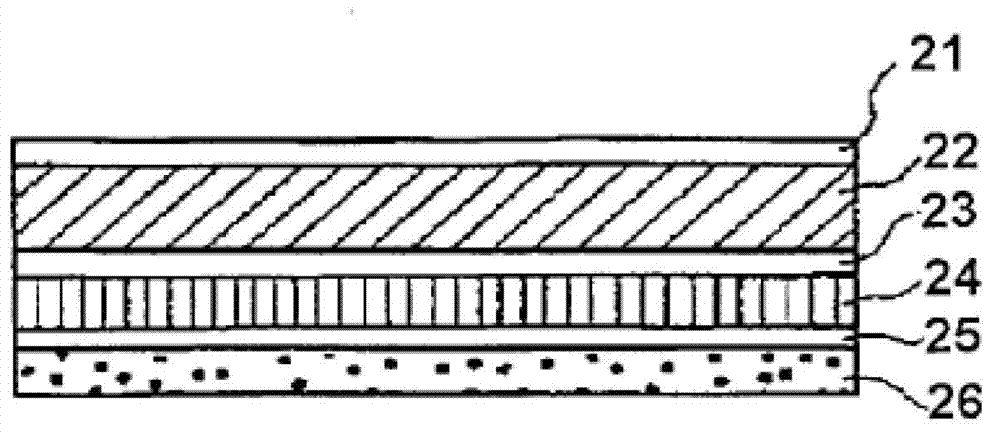

[0023] Such as figure 2 with image 3 As shown, a packaging container of the present invention includes the outermost layer 21 of thermoplastic material, the core layer 22, the middle layer 23 of thermoplastic material, the barrier layer 24, the adhesive layer 25 and the innermost layer 26 of thermoplastic material from outside to inside.

[0024] The thermoplastic middle layer 23 comprises metallocene catalyst-polymerized linear low-density polyethylene (MLLDPE) and low-density polyethylene (LDPE), wherein the metallocene-catalyzed linear low-density polyethylene (mLLDPE) has the following parameters: the average density is 0.88g / cm 3 ~0.925g / cm 3 , Melt flow index (190℃, 2.16kg) is 5g / 10min~20g / 10min, peak melting point is 85℃~130℃, expansion ratio is 1.2~1.8; low density polyethylene (LDPE) has the following parameters: average density 0.90g / cm 3 ~0.925g / cm 3 , Melt flow index (190℃, 2.16kg) is 5g / 10min~20g / 10min, peak melting point is 85℃~110℃, expansion ratio is 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Peak melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap