Non-equivalent atomic ratio cocrfenimo x High entropy alloy and its preparation method

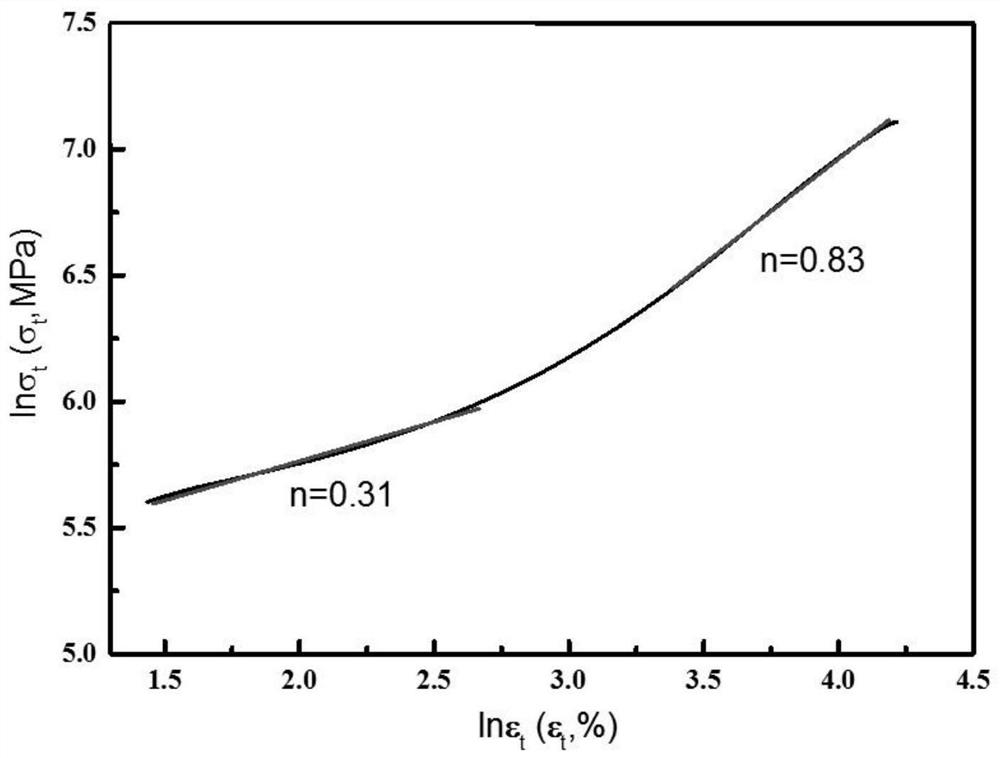

A high-entropy alloy, co30cr30fe18ni18mo4 technology, applied in the field of CoCrFeNiMox high-entropy alloy and its preparation, can solve the problems of low machinability and poor plasticity of high-entropy alloy, and achieve the advantages of short preparation period, improved alloy performance, and improved strength and plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

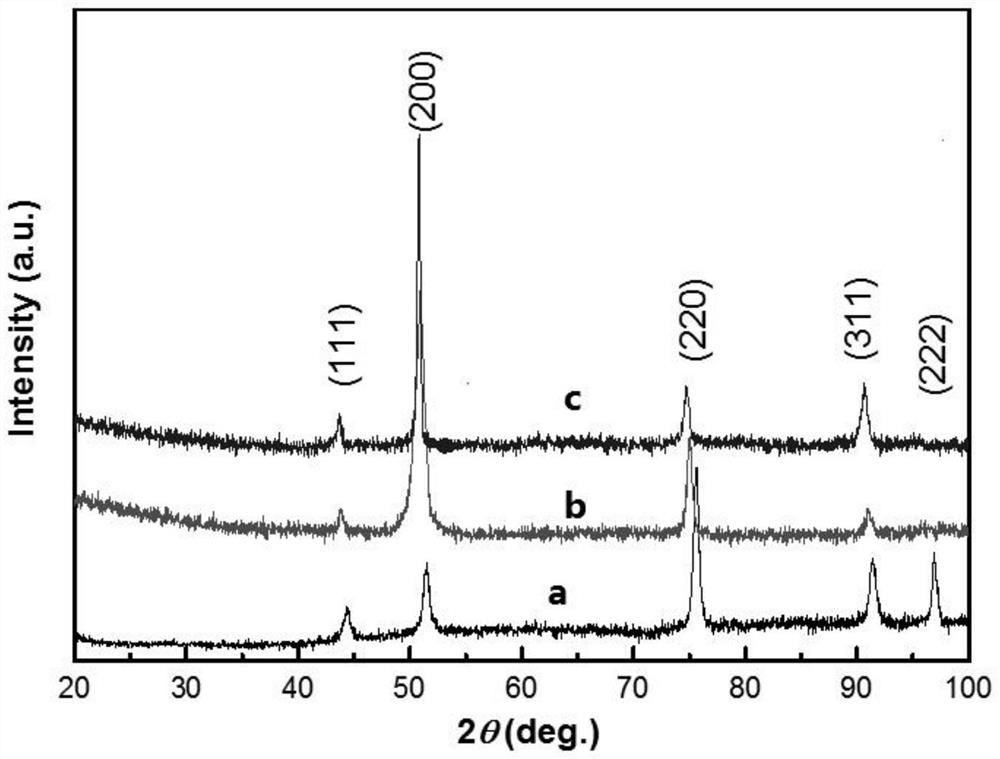

[0018] Specific implementation mode 1: CoCrFeNiMo with non-equiatomic ratio in this implementation mode x The expression for the high entropy alloy is CoCrFeNiMo x , where x is 0, 2 or 4, and is composed of the following raw material components according to the atomic percentage: Mo is 0% to 20%, Co is 10% to 40%, Cr is 10% to 40%, and Fe is 10% to 25%. %, Ni is 10% to 25%, and the sum of the atomic percentages of the above components is 100%.

[0019] In this embodiment, each element is in a non-equivalent atomic ratio.

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: CoCrFeNiMo x High-entropy alloys consist of 30% Co, 30% Cr, 18% Fe, 18% Ni, and 4% Mo in atomic percent, expressed as Co 30 Cr 30 Fe 18 Ni 18 Mo 4 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: CoCrFeNiMo x High-entropy alloys consist of 30% Co, 30% Cr, 19% Fe, 19% Ni, and 2% Mo in atomic percent, expressed as Co 30 Cr 30 Fe 19 Ni 19 Mo 2 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com