Packaging container

一种包装容器、热塑性材料的技术,应用在化学仪器和方法、合成树脂层状产品、分层产品等方向,能够解决能源浪费、原材料浪费等问题,达到颈缩现象减小、密封强度好、能源和原材料浪费现象抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

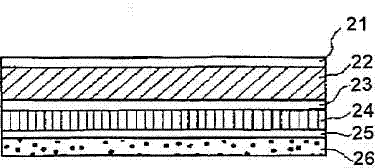

[0024] Such as figure 2 with image 3 As shown, a packaging container of the present invention includes an outermost layer 21 of a thermoplastic material, a core layer 22, an intermediate layer 23 of a thermoplastic material, a barrier layer 24, an adhesive layer 25 and an innermost layer 26 of a thermoplastic material in order from the outside to the inside.

[0025] The innermost layer 26 of the thermoplastic material contains linear low-density polyethylene (MLLDPE) and low-density polyethylene (LDPE) polymerized with a metallocene catalyst. The linear low-density polyethylene (mLLDPE) polymerized with a metallocene catalyst has the following parameters: average density 0.88g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / 10min, peak melting point is 85℃~130℃, expansion ratio is 1.2~1.8; low density polyethylene (LDPE) has the following parameters: The average density is 0.90g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com