Optical adhesive fast drying method during capacitive touch screen laminating process

A capacitive touch screen, fast drying technology, applied in the field of electronic information, can solve the problems of high first pressure rebound rate, unsatisfactory drying effect, weak solid optical adhesive adhesion, etc., and achieves rebound suppression, strong promotion and application value, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Take a piece of ITO glass (TP) with a size of 110mm x 56mm x 1.0mm and a piece of optical glue with the same size and a thickness of 175um, first paste the two together, then put them in a vacuum drying oven, Heat the vacuum drying oven to about 50°C, and evacuate the air pressure to below 0.3pa, keep it dry for 1 hour, take it out, attach it to the tempered glass cover, and then place the bonded module on the Put it into a high-pressure degassing machine for hot-pressing and degassing, take it out after 45 minutes, and check the packaging after cooling.

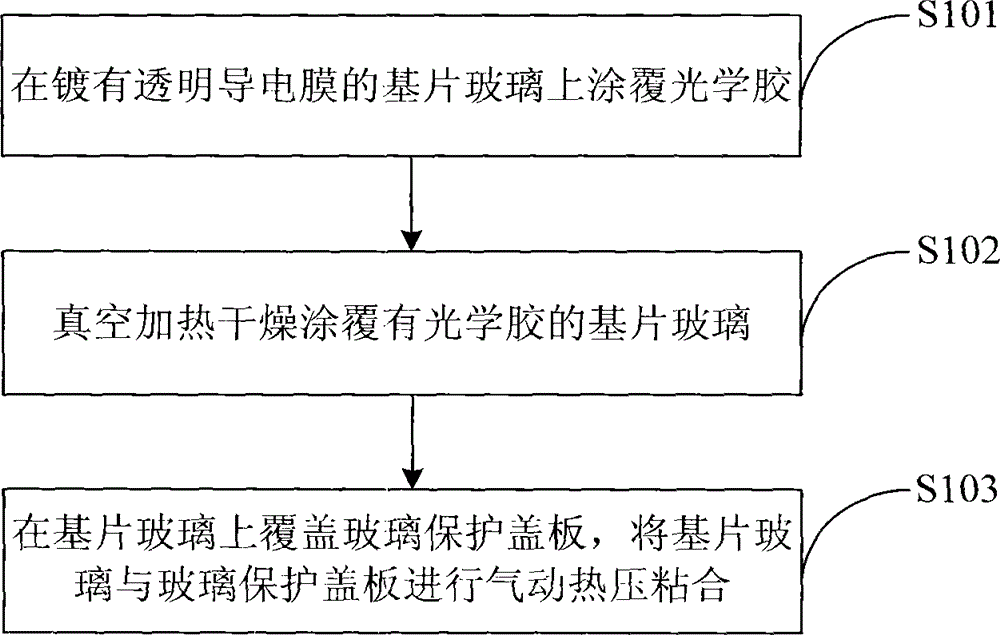

[0030] A kind of optical adhesive rapid drying technology in the bonding process of the capacitive touch screen of the present invention, the process step is: on the substrate glass coated with transparent conductive film, coating optical adhesive (thickness is 200um), then in a vacuum oven Heating and drying, the temperature is about 50°C, the air pressure is below 0.3pa, and the drying time is 15min. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com