Method and device for braking track-bound vehicles driven by induction motors

An induction motor and vehicle technology, applied in the field of rail vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

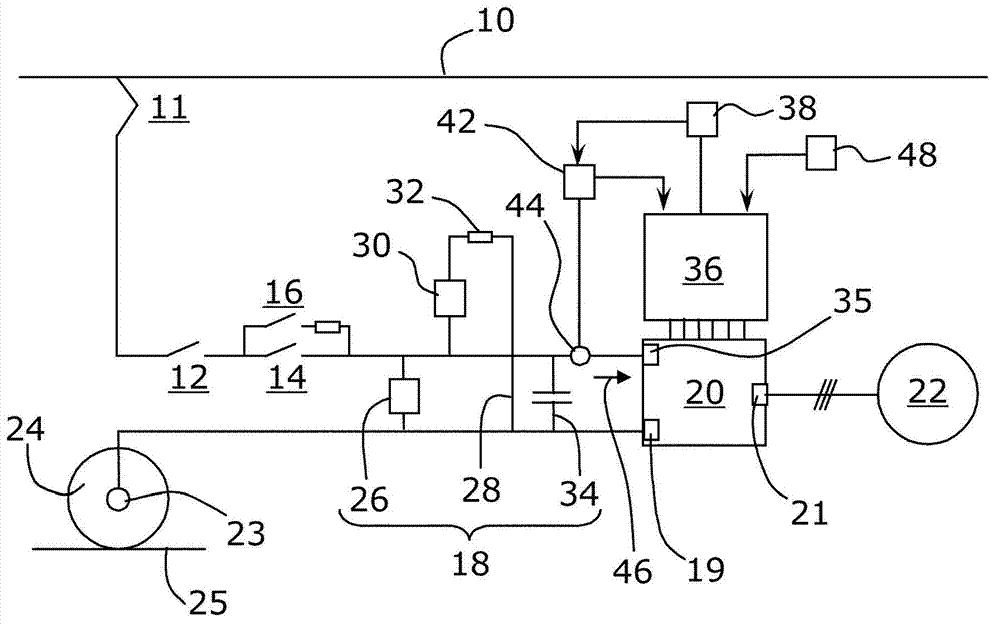

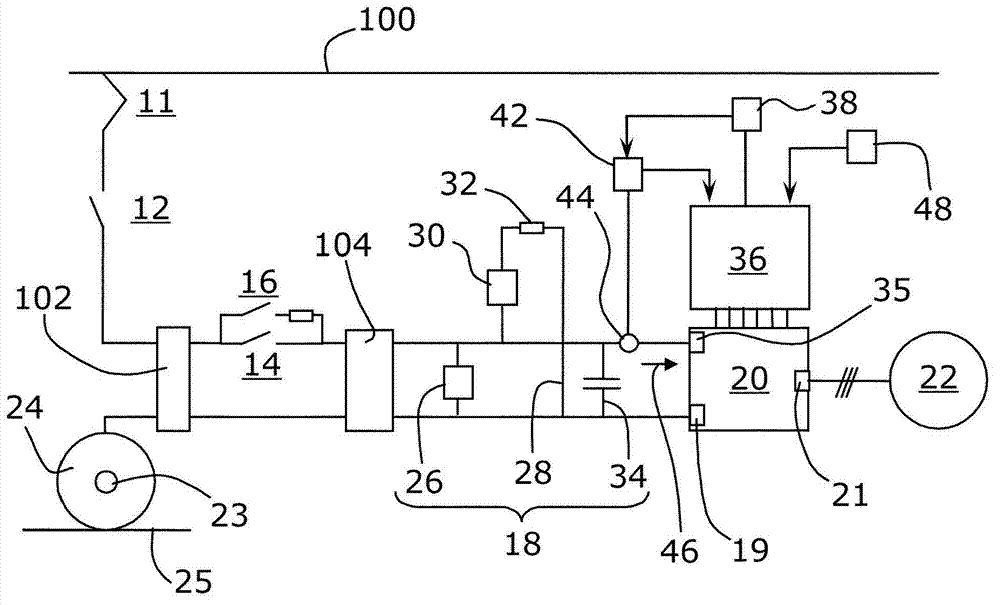

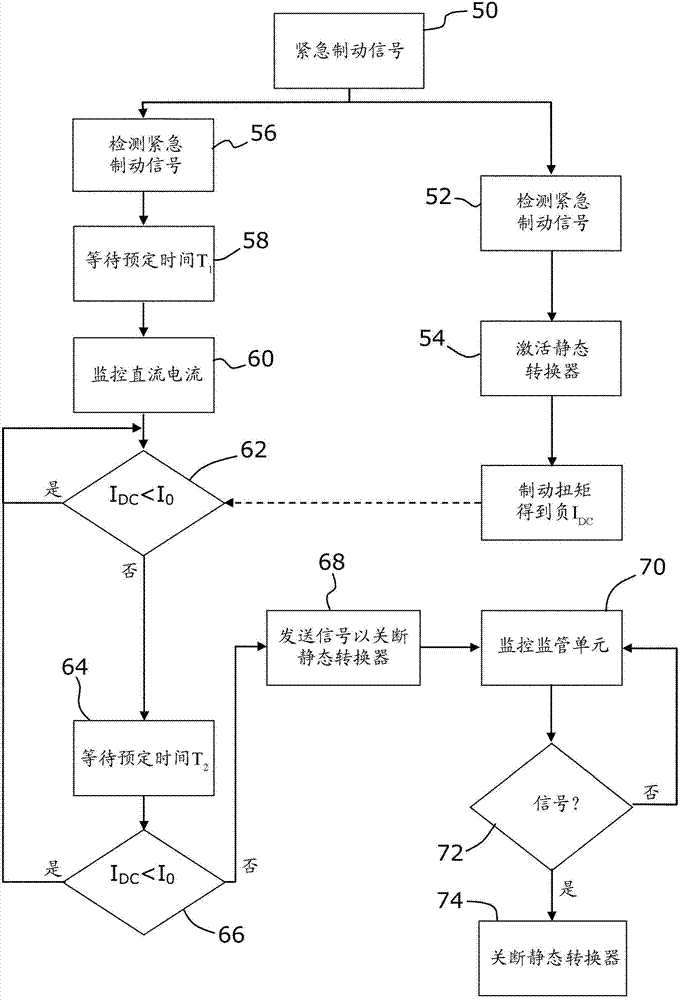

[0041] refer to figure 1 , for rail vehicles, more specifically, a combined electric drive and braking system for rail vehicles powered by a DC catenary line 10 or a transmission rail, comprising a collector 11, a circuit breaker 12, and a separation contactor 14 , the separation contactor 14 is connected in parallel with the charging contactor and the resistance unit 16 . The electric drive and braking system also includes a DC link 18 connected to a DC terminal 19 of a static converter 20 for converting the DC current of the DC link into a three-phase AC current. The static converter 20 has AC terminals 21 connected to an induction motor 22 mechanically linked to an axle 23 of the rail vehicle. The axle 23 is also provided with conventional friction brakes (not shown). The drum 24 of the axle 23 closes the circuit and allows the current to flow back to the supply station via a rail 25 connected to ground.

[0042] The DC link 18 comprises a return unit 26 connected in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com