Obstacle remover components and EMUs

A technology of obstacle remover and EMU, which is applied to railway car body components, railway vehicle wheel guards/buffers, transportation and packaging, etc., which can solve the problems that airflow cannot flow away and increase the resistance of tail cars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

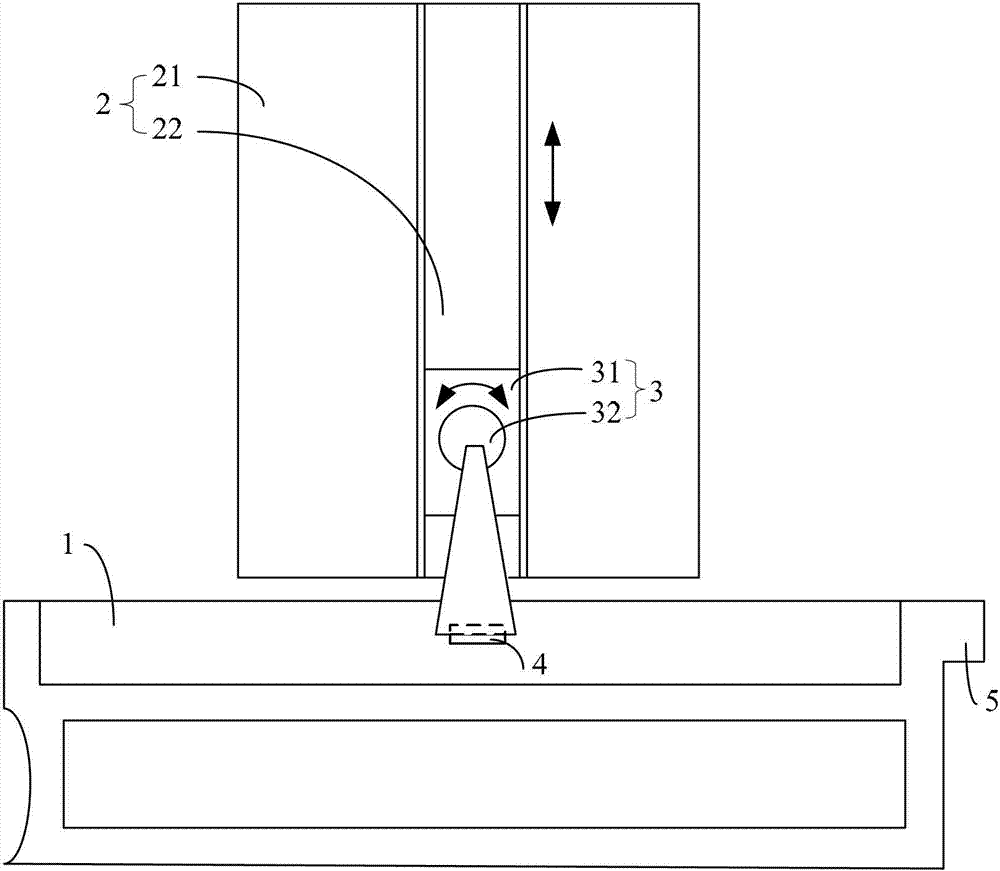

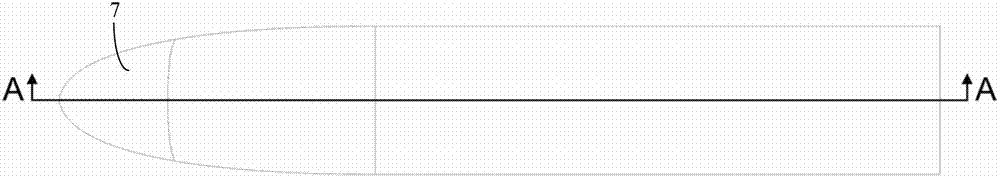

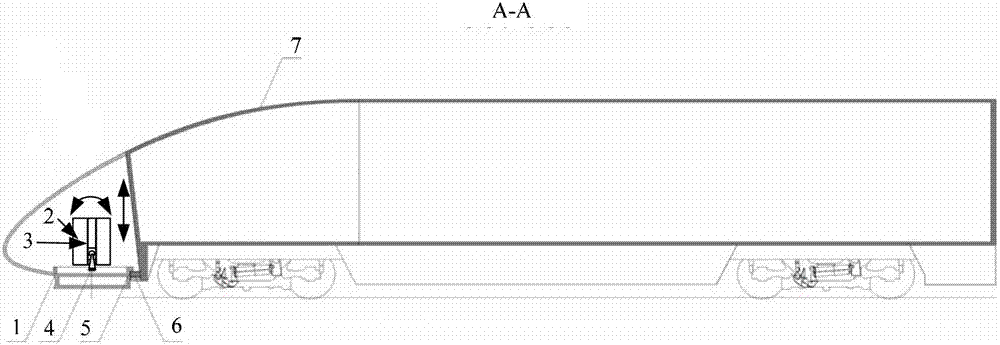

[0032] figure 1 It is a schematic structural diagram of the obstacle remover assembly provided by Embodiment 1 of the present invention, figure 2 for figure 1 The schematic diagram of the top view of the block remover assembly used on the EMU, image 3 for figure 2 A-A sectional view of, Figure 4 for image 3 The partially enlarged schematic diagram of Figure 5 for Figure 4 The schematic diagram after the obstacle remover on the EMU is raised, Figure 6 for Figure 5 The schematic diagram after the obstacle remover on the EMU is rotated, Figure 7 for figure 2 The schematic diagram of looking up, Figure 8 for Figure 7 A partially enlarged schematic diagram.

[0033] see Figure 1-Figure 8 , Embodiment 1 of the present invention provides an assembly of an obstacle remover 1, which includes an obstacle remover 1 and an installation part, the installation part includes a fixed part 2 and a moving part 3, and the fixed part 2 is used to be fixed on the head of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com