Railway vehicle telescopic head and railway vehicle

A technology for rail vehicles and locomotives, applied in the field of rail vehicles, can solve the problems of loose tail scrolls and large aerodynamic resistance of fast-back car shape, and achieve the effects of reducing rear resistance, eddy current resistance, and reducing running resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

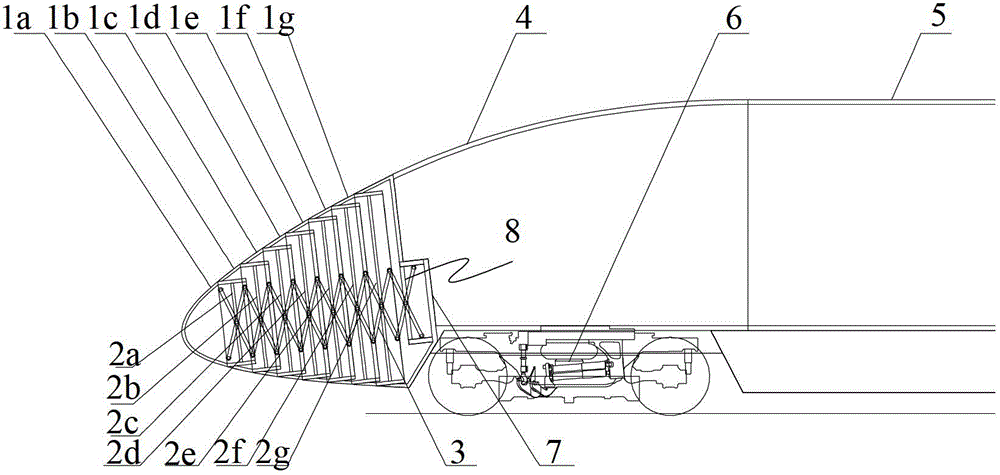

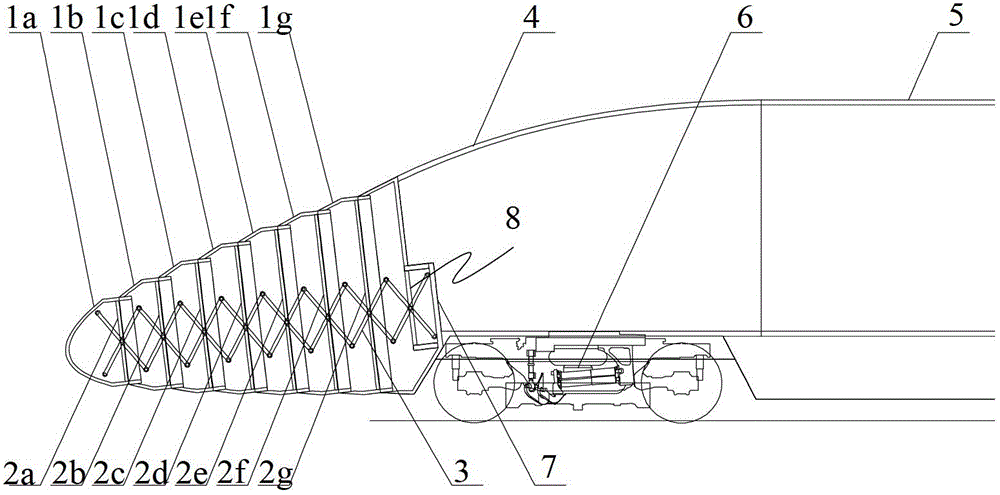

[0019] figure 1 A schematic diagram of a rail vehicle provided by an embodiment of the present invention; figure 2 for figure 1 A sectional view of the front end along A-A in the center; image 3 for figure 1 A cross-sectional view of the rear end of the car along the middle line A-A; Figure 4 It is a partial enlarged view of the nose cone of the car; Figure 5 for Figure 4 right view of Figure 6 It is a schematic diagram of the assembled state of the rail vehicle; Figure 7 It is a schematic diagram of a rail vehicle driving from station X to station Y; Figure 8 is a schematic diagram of a rail vehicle driving from station Y to station X; for example Figure 1-8 As shown, the embodiment of the present invention provides a telescopic locomotive for rail vehicles. The locomotive is composed of a locomotive front end 1 and a locomotive body 4 that are rotatably connected. Shaped segment body, the telescopic frame and at least one connecting rod 20 arranged in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com