Novel structural material water pump

A new structure, water pump technology, applied to pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of weak coating adhesion, high spraying process cost, reduction of water and flow channels, etc. Miscellaneous effects, resistance reduction, friction resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

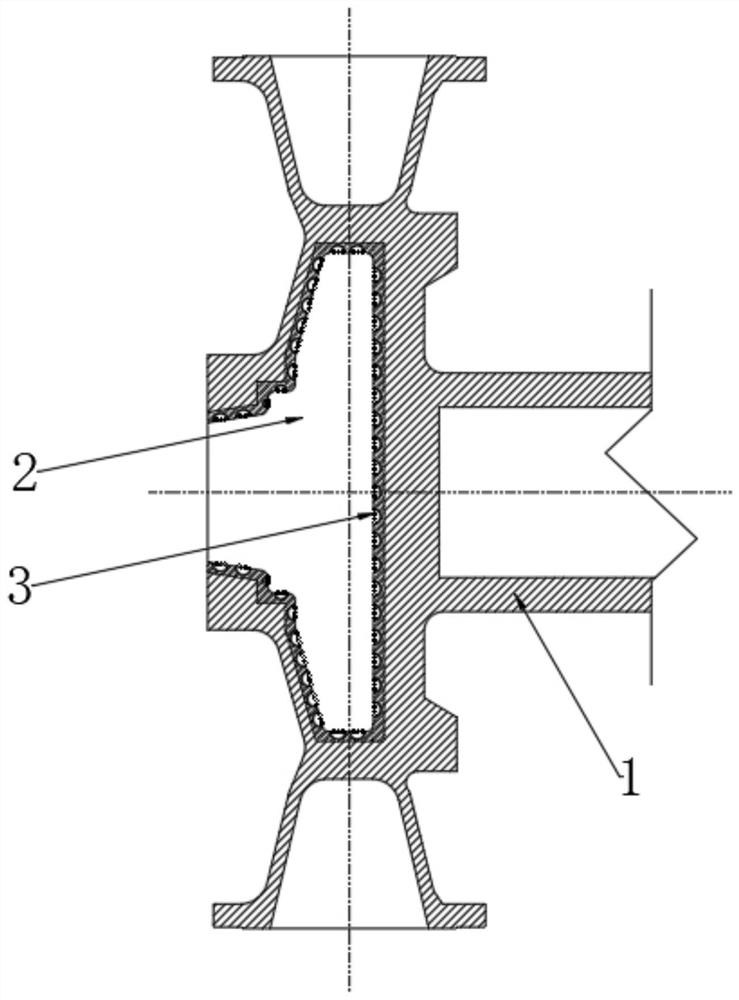

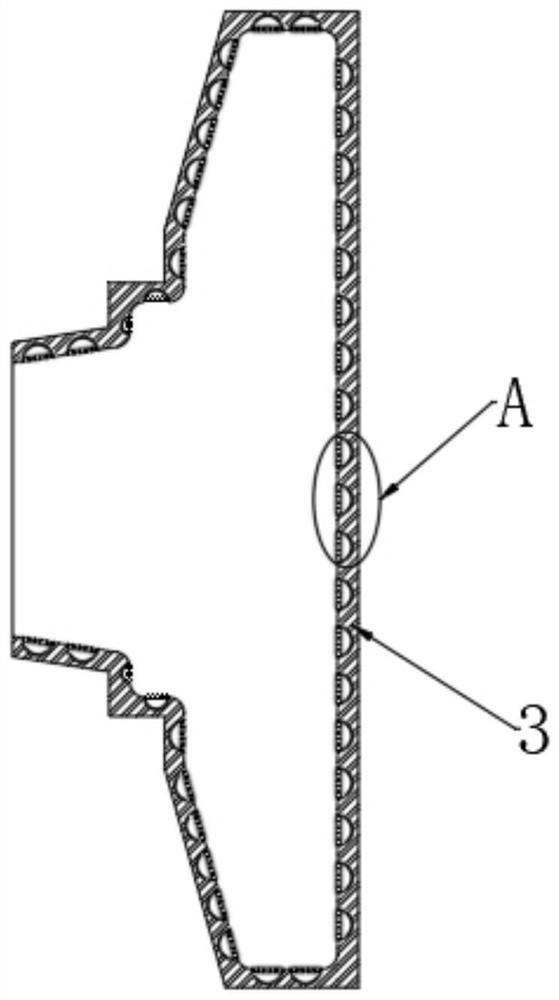

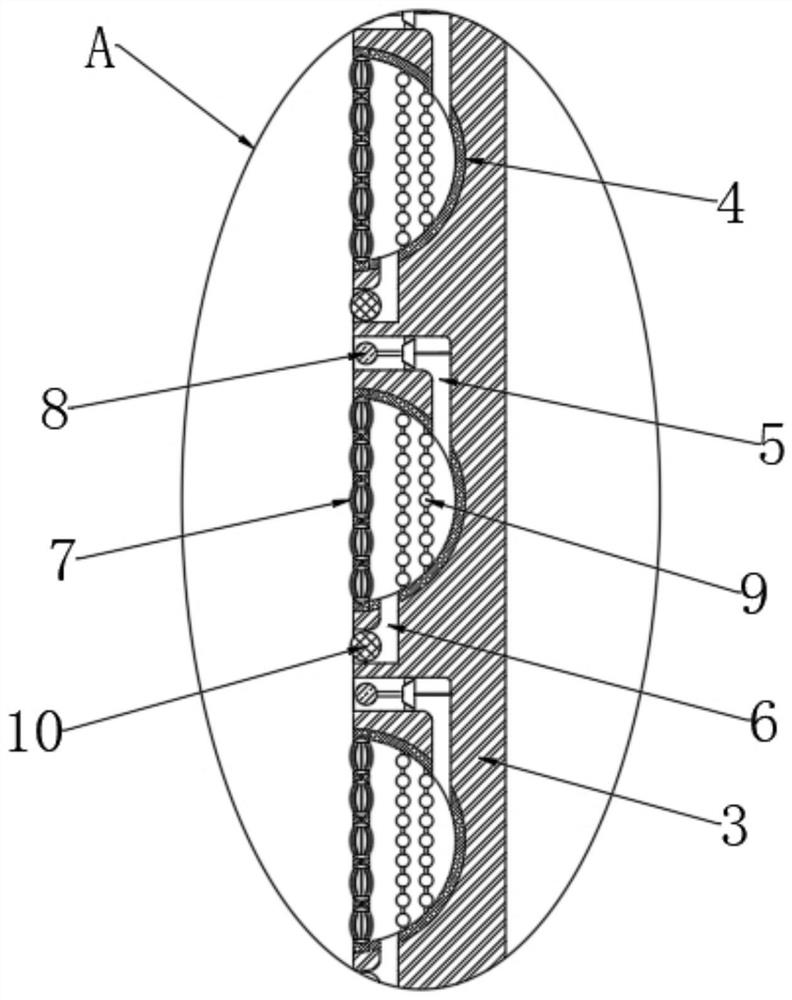

[0045] see Figure 1-8 , a new structural material water pump, including the water pump body 1, please refer to Figure 1-2 The water pump body 1 includes a flow channel 2, the inner wall of the flow channel 2 is fixedly inlaid with a smooth liner 3, and the side wall of the smooth liner 3 is fixedly inlaid with a plurality of hollow relief pockets 4, which are semi-spherical structures, And the end face of the relief bag 4 is flush with the surface of the smooth liner 3, in order to keep the smoothness of the smooth liner 3 and avoid the occurrence of large turbulent flow, the inner wall of the spacer 4 is fixedly connected with a plurality of impurity-removing particles 9, see Figure 8 The impurity removal particles 9 include a plurality of adsorption particles 902, and a connecting rod 901 is fixedly connected between two adjacent adsorption particles 902. The adsorption particles 902 are used to filter the water entering the interior of the space bag 4, thereby carrying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com