Recycling process and system for wooden activated carbon industrial wastewater

A technology for wood activated carbon and waste water production, which is applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of increasing construction investment and complexity, and achieve convenient production Arrangement, reduce production cost, improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

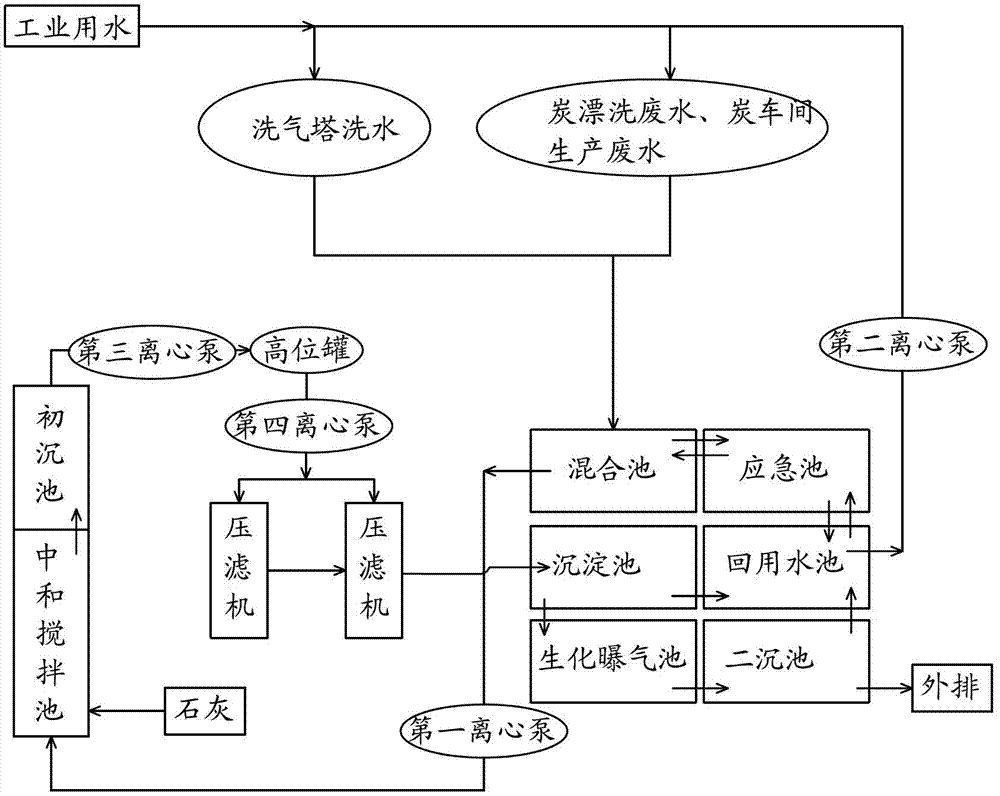

[0029] Please refer to figure 1 As shown, the wooden activated carbon production waste water reuse treatment system of the present embodiment includes a mixing tank, a neutralization stirring tank, a primary sedimentation tank, a high-level tank, a filter press, a sedimentation tank and a reuse water tank connected in sequence, and the mixing tank There is also a first channel for feeding activated carbon rinsing wastewater, activated carbon workshop production wastewater and scrubber washing water. The neutralization mixing tank is also provided with a second channel for adding milk of lime. The reused water tank is also provided with There is a water outlet channel through which the reused water pool delivers recycled water to the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com