Matte glass manufacturing method

一种玻璃制造、雾面的技术,应用在玻璃制造设备、制造工具、玻璃的钢化等方向,能够解决环境污染、作业人员化学伤害、安全隐患等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

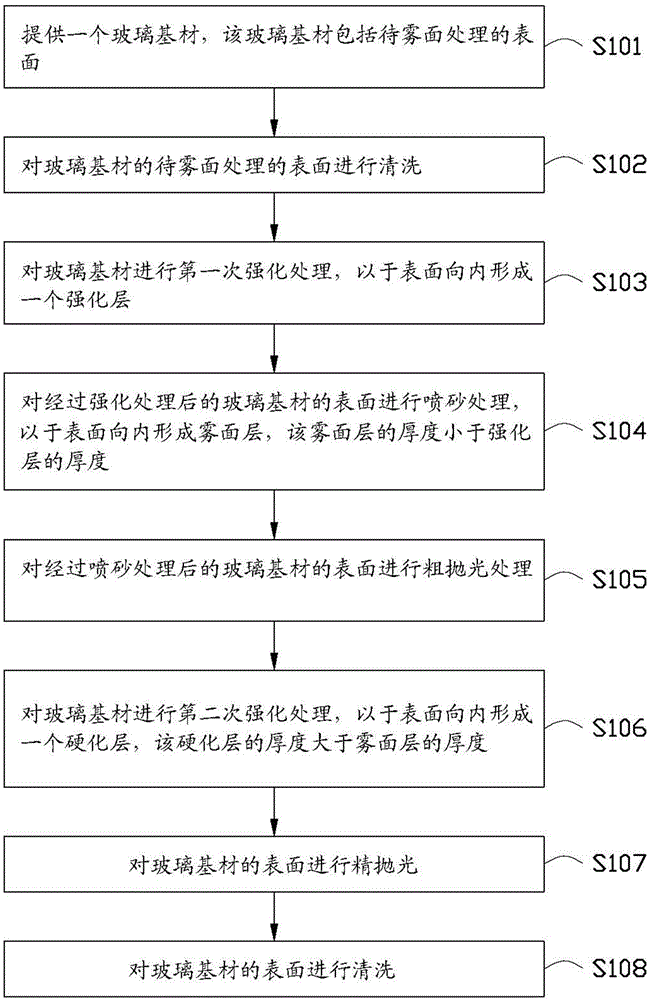

[0025] see figure 1 and figure 2 , the manufacturing method of frosted glass according to the embodiment of the present invention comprises the following steps:

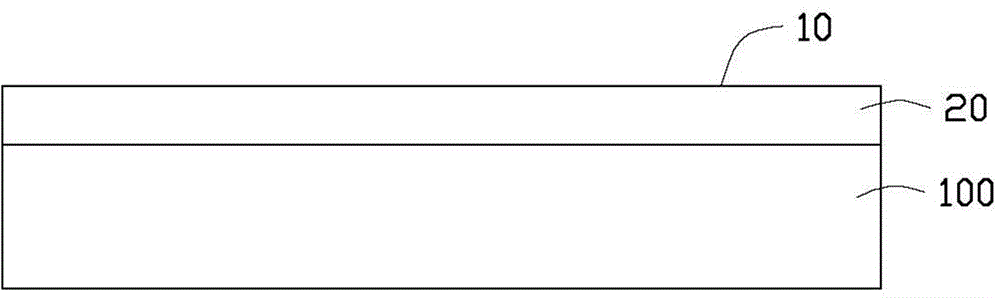

[0026] In step S101 , a glass substrate 100 is provided, and the glass substrate 100 includes a surface 10 to be fogged.

[0027] In step S102, the surface 10 of the glass substrate 100 to be matted is cleaned. In this embodiment, the surface 10 of the glass substrate 100 to be matted is cleaned by ultrasonic waves, so as to remove dust and oil stains on the surface 10 .

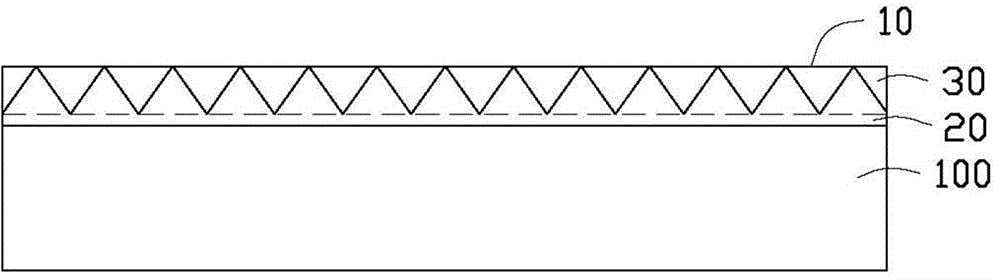

[0028] In step S103 , a first strengthening treatment is performed on the glass substrate 100 to form a strengthening layer 20 inwardly from the surface 10 . During the strengthening treatment for the first time, the surrounding surface of the glass substrate 100 is first masked so that only the surface 10 that needs to be matted is exposed, and then the glass substrate 100 after the masking treatment is placed in 400- Molten Potassium Nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com