Method for preparing mixed-color single yarns and device for implementing method

A manufacturing method, technology of mixed color single yarn, applied in yarn, spinning machine, textile and paper making, etc., can solve problems such as monotonous color, and achieve the effect of strong three-dimensional effect, unique style and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

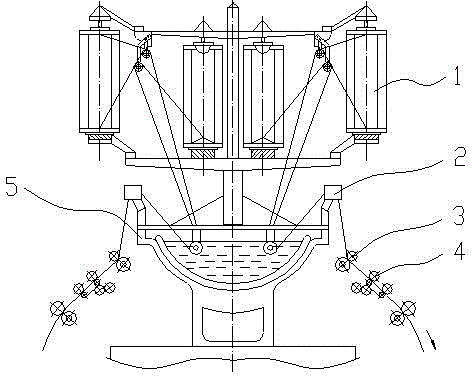

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0021] In this embodiment, a method for manufacturing mixed-color single yarn has the following steps:

[0022] 1. Choose single-color yarn according to the design requirements of product color, and install different single-color yarns on different roving bobbins.

[0023] 2. Each strand of single-color yarn enters the water tank through the guide wheel for wet spinning.

[0024] 3. The untwisting process is carried out separately and synchronously for each single-color yarn, that is, the single-ply yarn is reversed so that the yarn fibers are spread out flat.

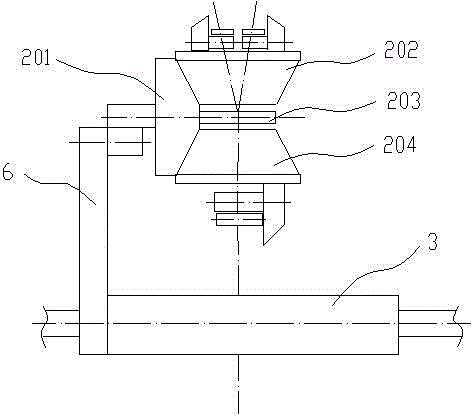

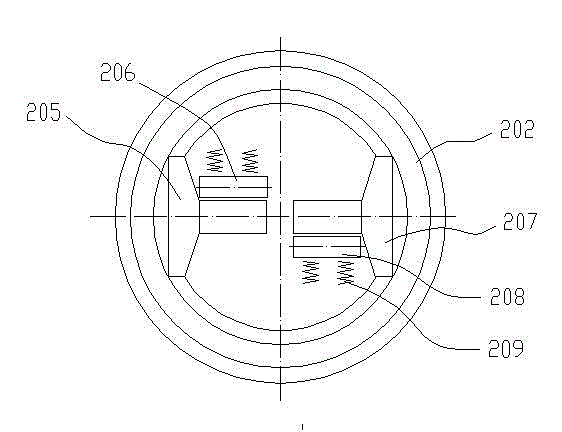

[0025] 4. Adjust the pressure between the combined pressure rollers in the pressure roller device, and guide the untwisted monochromatic yarn into the pressure roller device.

[0026] 5. Send multiple single-color yarns to the twisting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com