Multi-section combined intelligent partition door drive system

A transmission system and intelligent system technology, applied in door/window fittings, power control mechanisms, buildings, etc., can solve the problems of irregular, cumbersome, and inconvenient double-layer upper tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

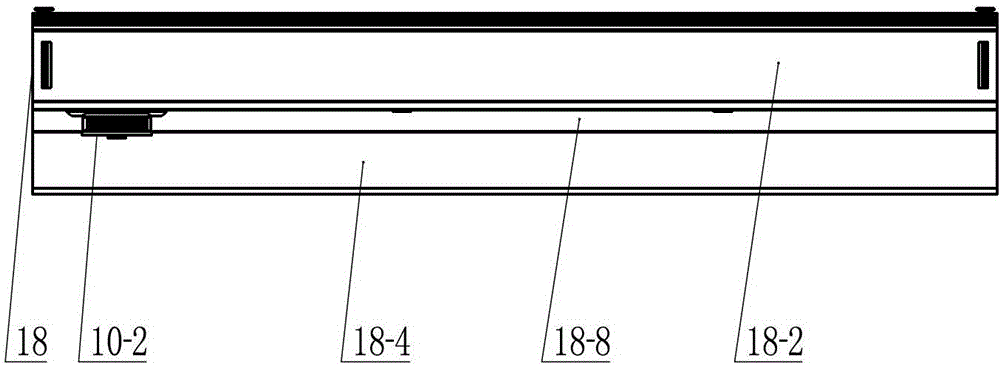

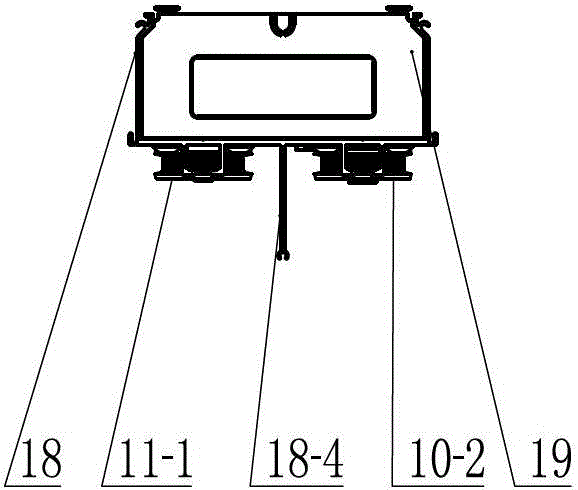

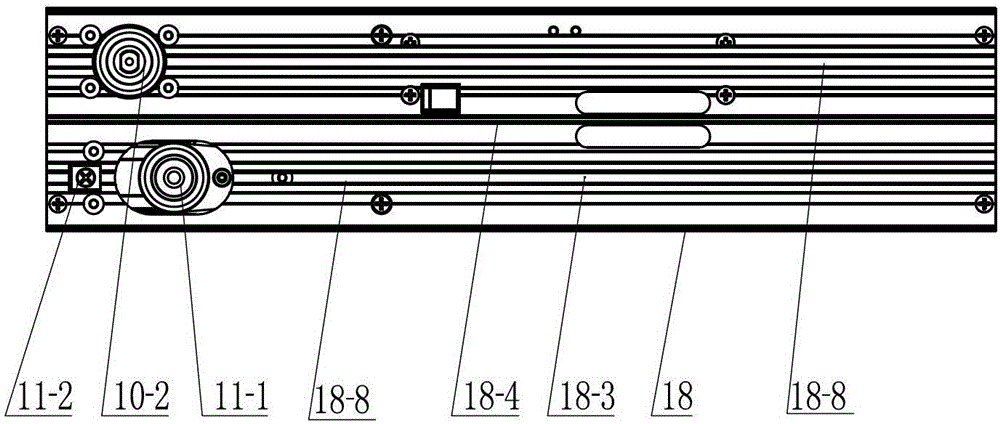

[0033] Each component of the present invention is manufactured according to each drawing of the present invention, and then assembled to obtain the present invention. The first invention point of the present invention is intelligent partition door transmission system intelligent partition door transmission system box body 18, which is a rectangular box body with end caps 19 assembled at both ends, and installed on the upper part of the intelligent partition door transmission system box body 18. The cover 20 is a closed box in actual application. And intelligent partition door drive system box body 18 is made up of upper strata plane 18-1, upper strata riser 18-2, lower floor top surface 18-3 and the vertical plate 18-4 in the middle part of lower floor top surface 18-3; There are connecting hooks 18-5 and top hooks 18-6 on the upper part of the outer side of 18-2, and vertical connecting hooks 18-7 on the lower part; there are two "冂" on the lower top surface 18-3 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com