Oilwell sleeve pressure test plug sealing structure

A technology of sealing structure and oil well casing, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as unfavorable production site construction, improve sealing performance and service life, and stabilize installation position , making easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

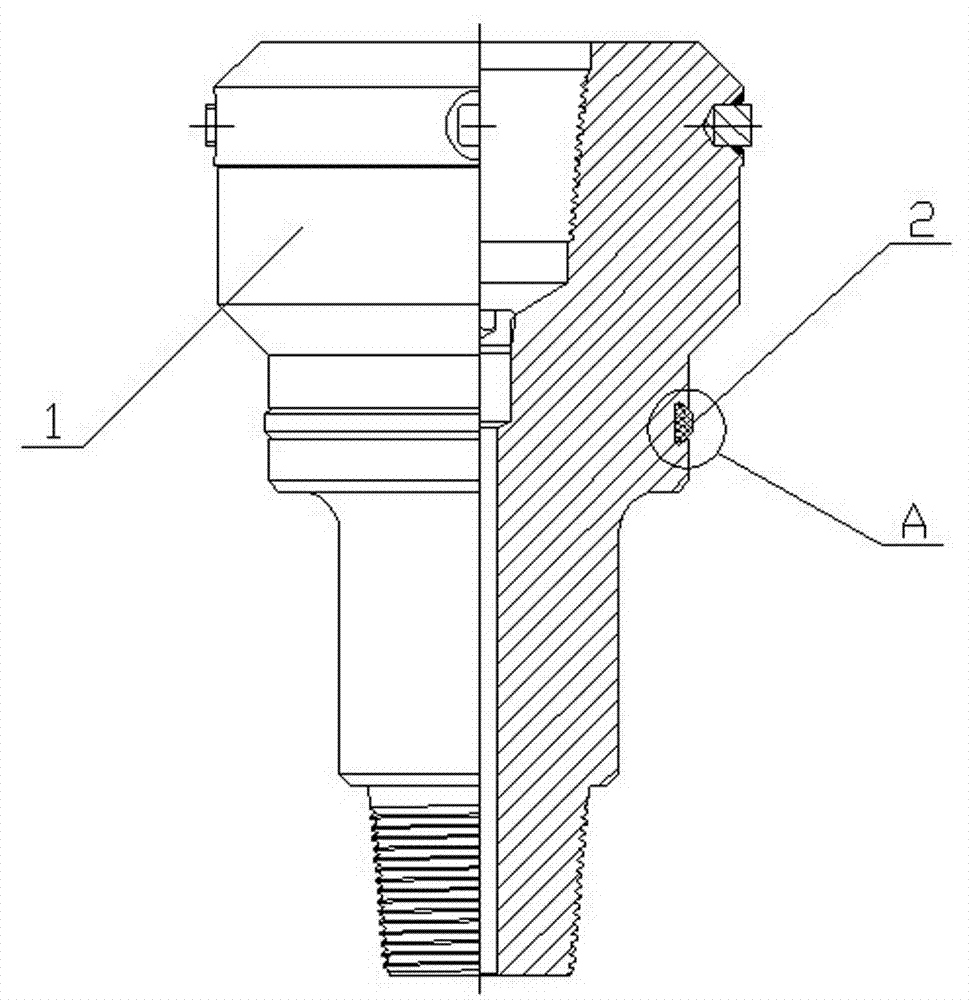

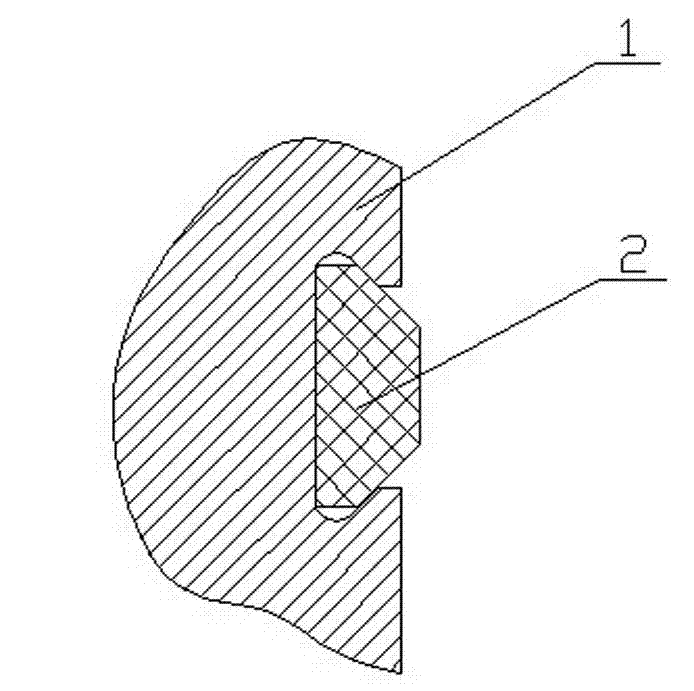

[0012] Combine below figure 1 The present invention is further described.

[0013] The oil well casing pressure test plug sealing structure shown in the accompanying drawing is composed of an annular groove on the outer wall of the pressure test plug 1 and a matching sealing ring 2 . The technical improvement of the present invention is that the transverse section of the annular groove on the outer wall of the pressure test plug 1 is dovetail-shaped, that is, the annular groove is wide inside and narrow outside. The sealing ring 2 with the same transverse cross-sectional shape is embedded in the annular groove, and the outer surface of the sealing ring 2 and the inner wall matched with the casing to be tested form a sealing pair. Because the sealing ring 2 is embedded in the annular groove on the outer wall of the pressure test plug 1, the installation position is stable. Even when the pressure test plug 1 and the casing are loaded and unloaded, the sealing ring 2 will not ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com