Rotor of Roots type vapor compressor

A steam compressor and Roots-type technology, applied in the field of Roots-type steam compressor rotors, can solve problems such as reducing energy saving effect, increasing motor power, affecting sealing effect, etc., to reduce contact area, improve sealing effect, friction force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

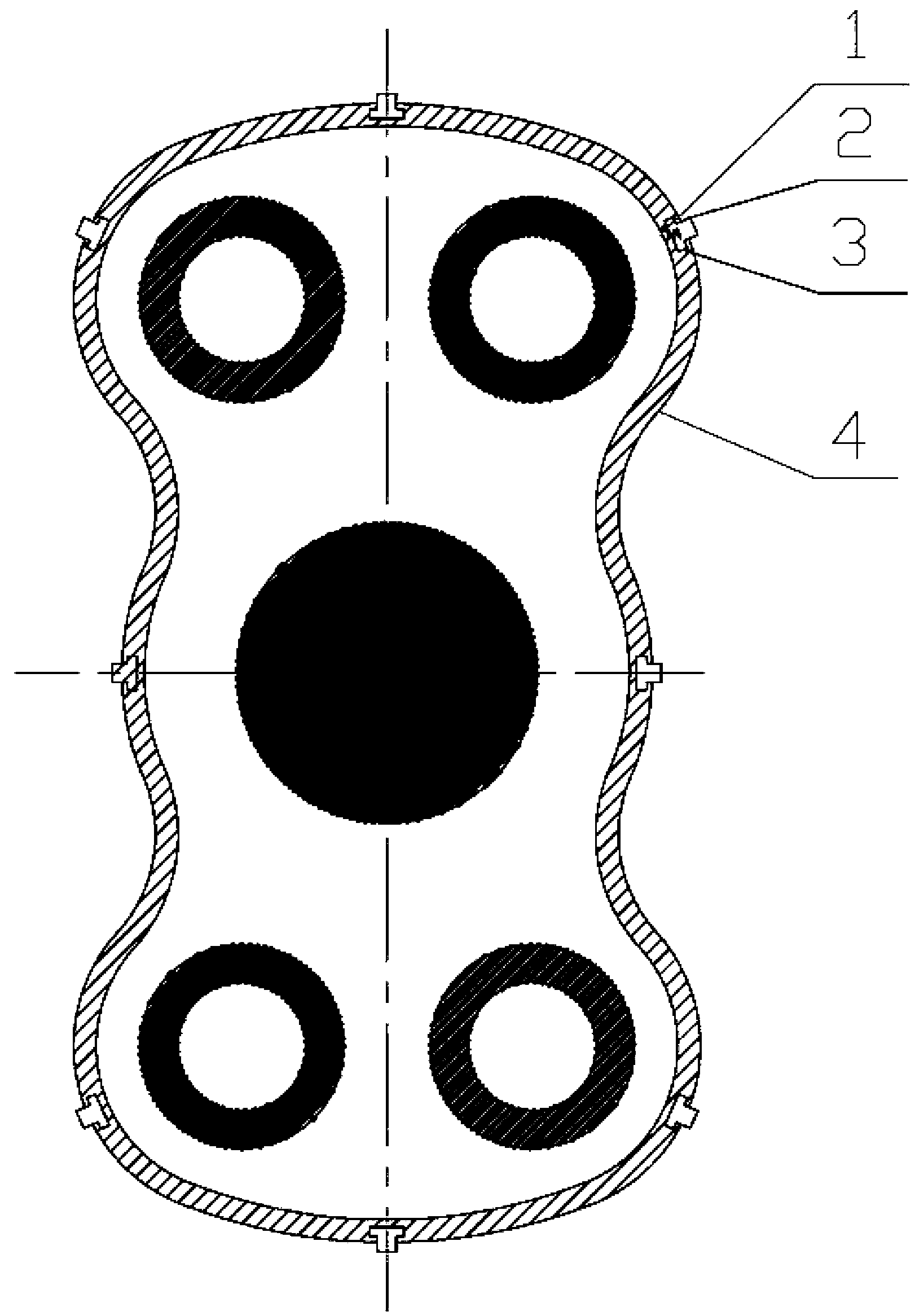

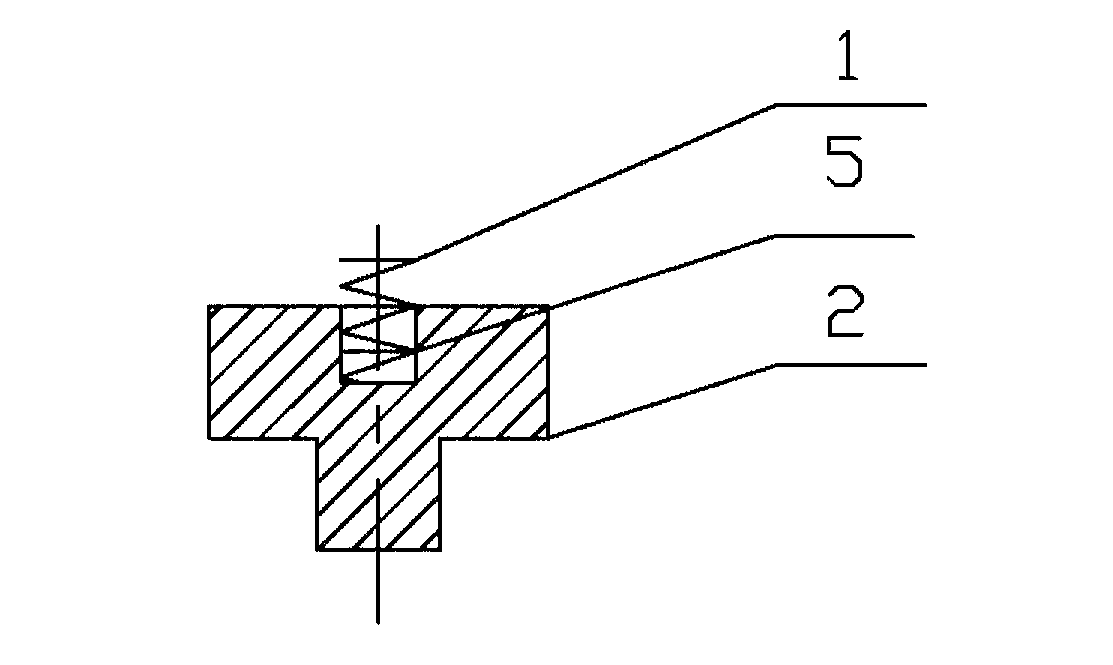

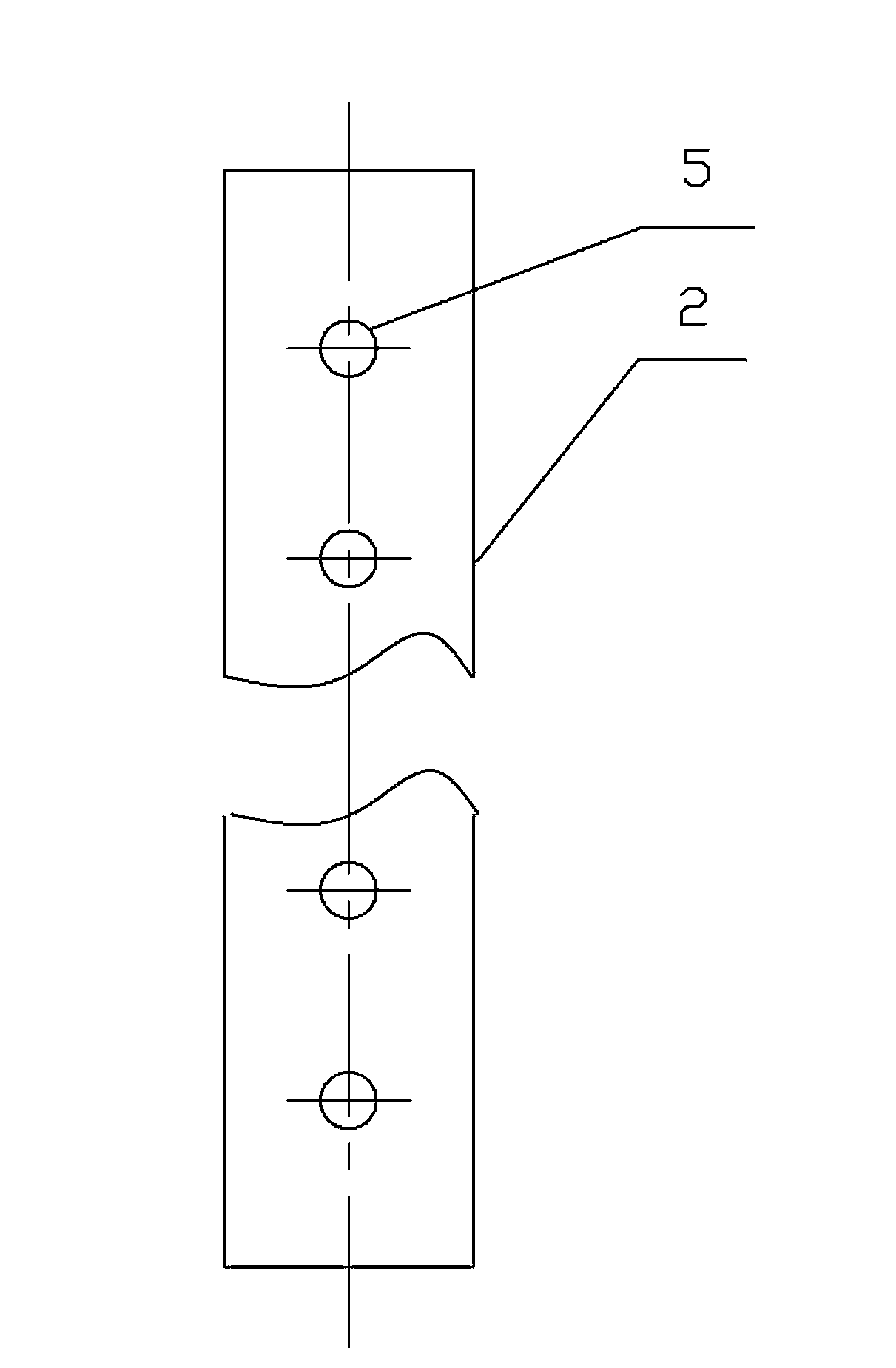

[0017] Such as Figure 1-Figure 3 As shown, the rotor of the Roots-type steam compressor of the present invention includes a rotor body 4 with a cross-section of "8" shape, grooves 3 are formed in parallel at regular intervals on the sealing surface of the rotor body 4, and the grooves 3 are installed There is a sealing strip 2 matching the groove 3, and the sealing strip 2 is made of C, H, F, and Si cross-linked composites. There is a small hole 5 on the bottom surface of the sealing strip 2, and one end of the wire-wound spring 1 is installed in the small hole 5 Inside, the other end abuts against the bottom surface of the groove 3, so that the sealing strip 2 protrudes from the surface of the rotor body 4, and the expansion gap is preset between the rotor body 4 and the casing. The grooves 3 are parallel to the axis of the rotor body 4, and the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com