Pin-type multi-chip synchronizer

A synchronizer and locking pin technology, applied in the direction of clutch, mechanical drive clutch, mechanical equipment, etc., can solve the problems of long shifting time and short service life of the locking pin synchronizer, so as to increase the scope of application, reduce costs, The effect of reducing the shift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments.

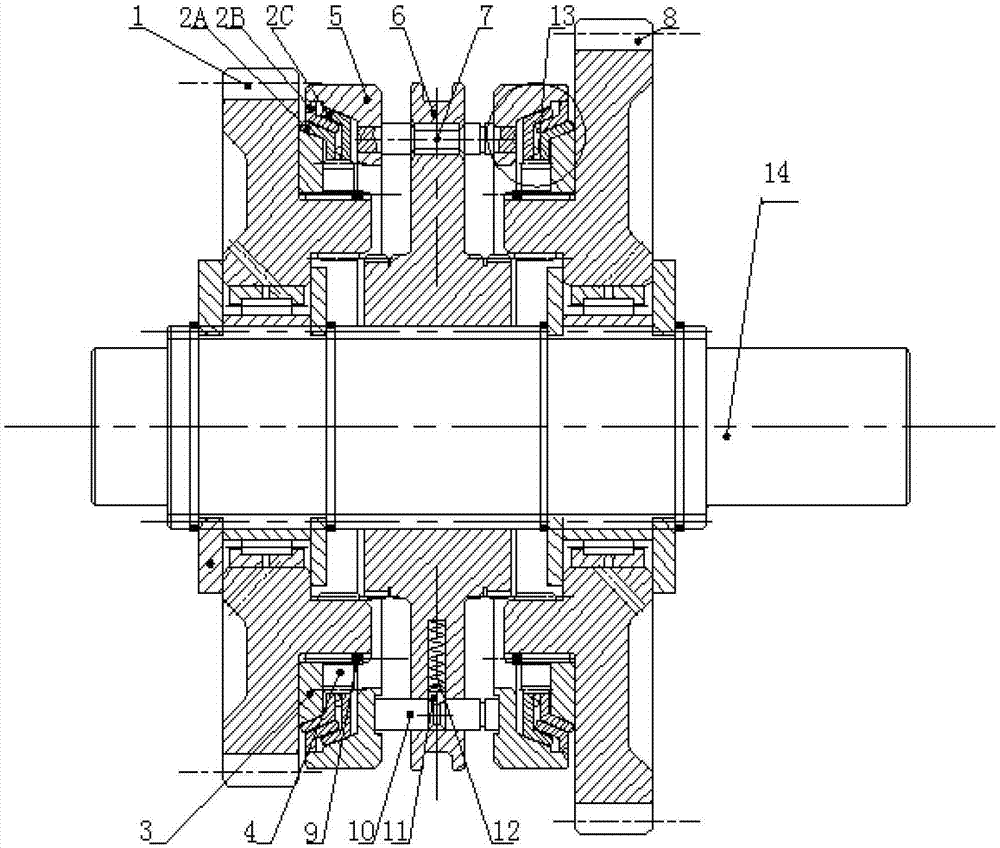

[0024] Take two gears as an example, such as figure 1 As shown, between the gear 1 and the gear 8 and the friction plate housing 5, three friction plates 2 of different shapes are installed in sequence, and the three friction plates 2 of different shapes are arranged obliquely; the coupling sleeve 6 and the output shaft 14 is directly engaged, the coupling sleeve 6 is connected with the friction plate housing 5 through the positioning pin 10; the lock pin 7 is rigidly connected with the friction plate housing 5. A spring 12 is installed in the radial hole of the coupling sleeve 6; in the neutral position, the steel ball 11 is placed in the groove of the positioning pin 10 under the pressure of the spring 12, so that the two friction plate housings 5 and the coupling sleeve 6 There is no relative movement.

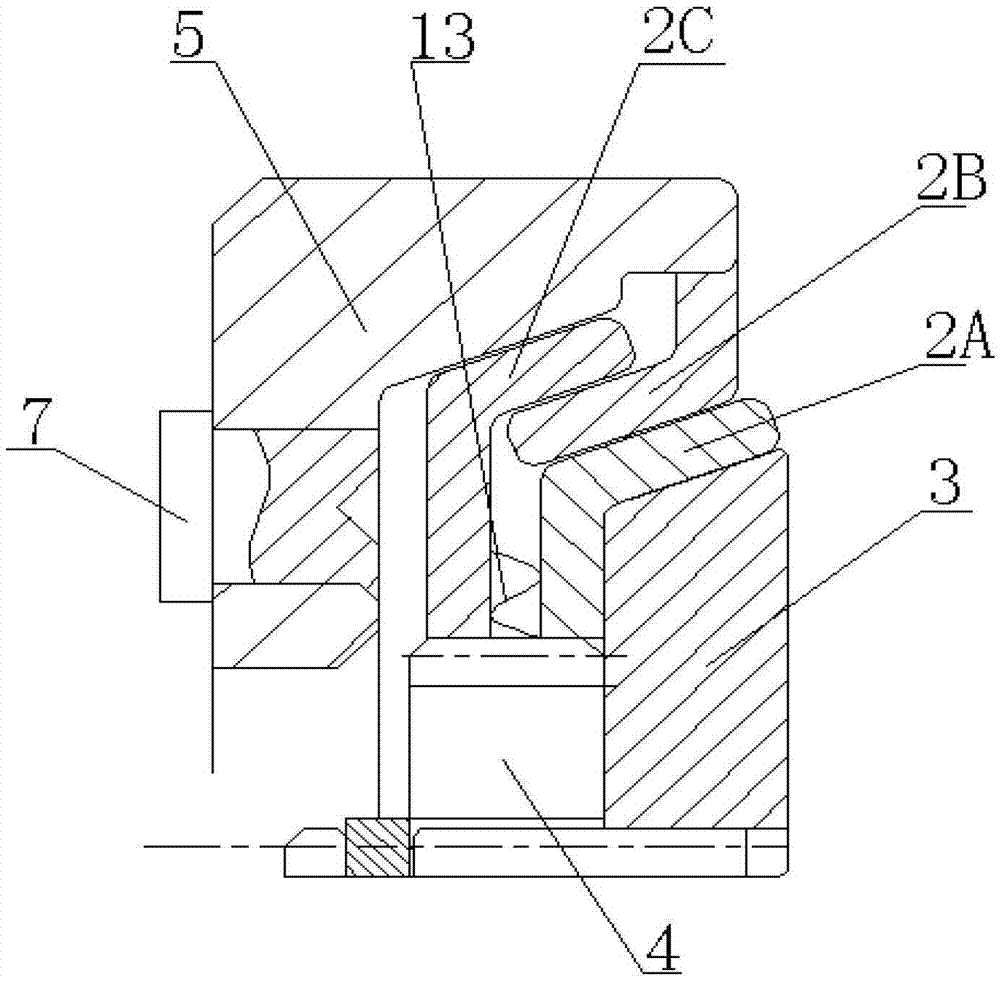

[0025] Such as figure 2 As shown, the upper ends of the outer spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com