Automatic gearbox

A technology for automatic transmissions and gearboxes, which is applied to transmissions, transmission parts, gear transmissions, etc., and can solve problems such as high maintenance costs and large impact forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

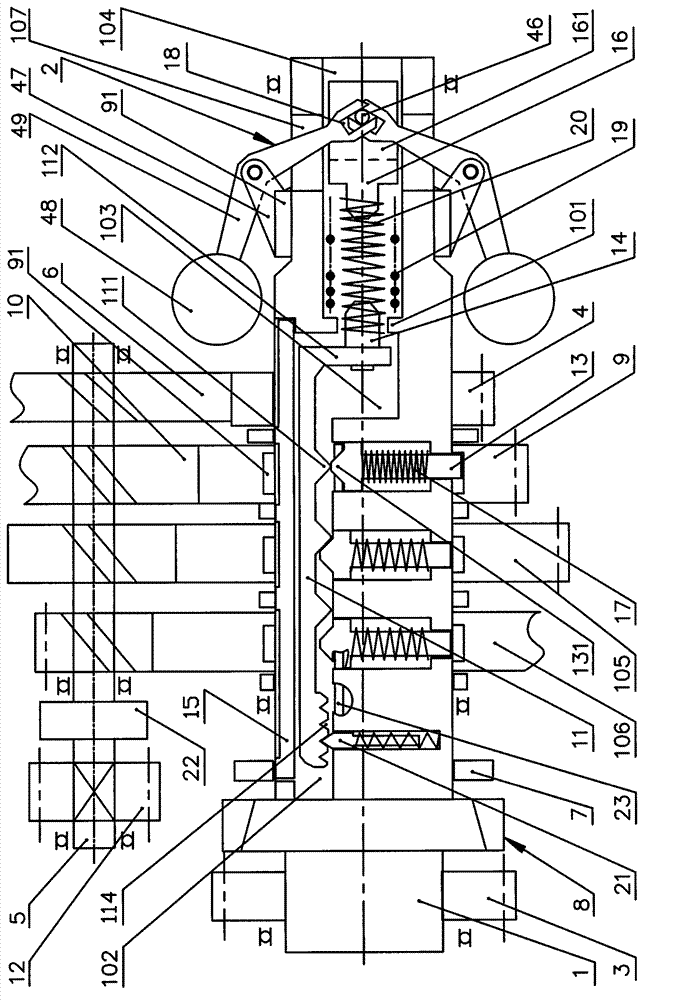

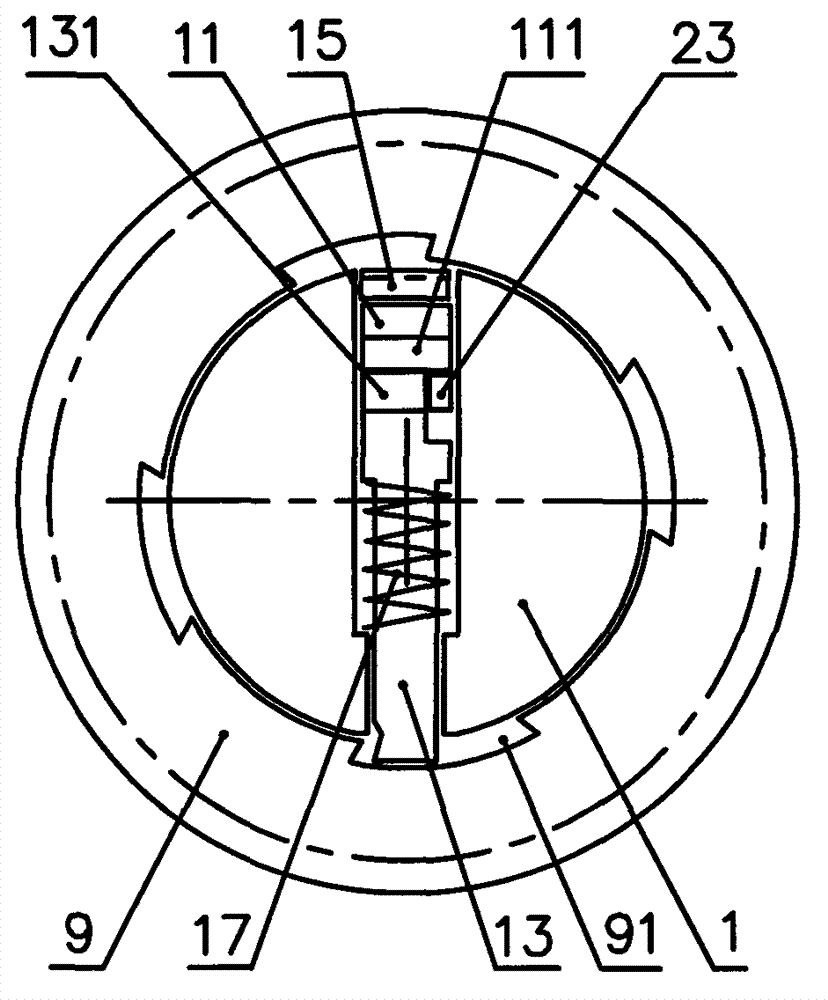

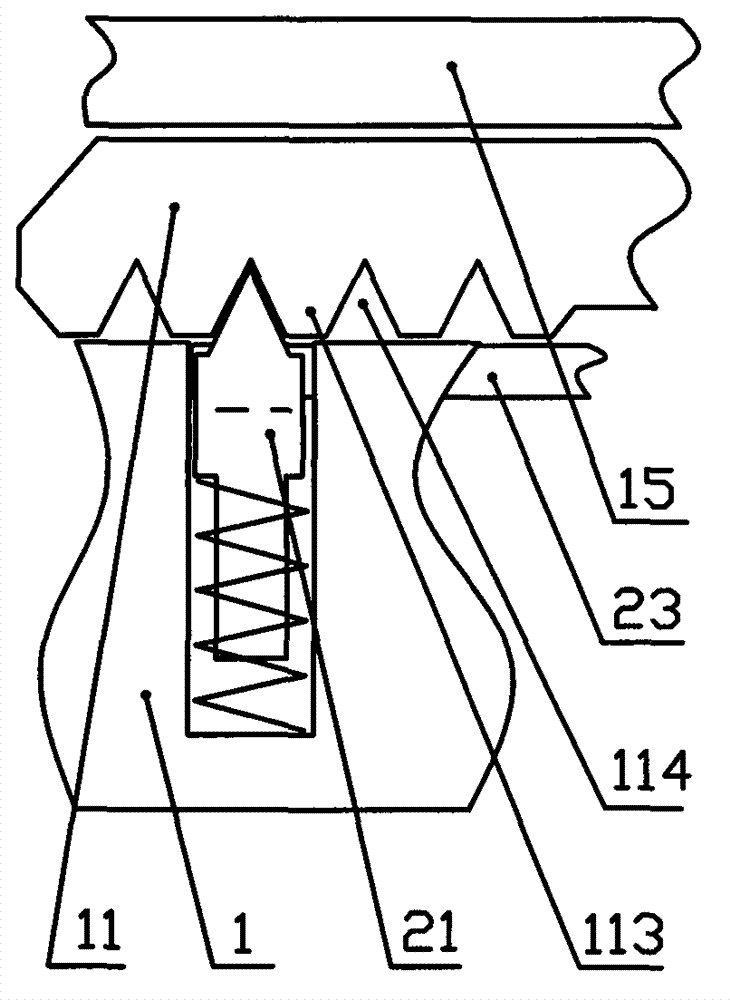

[0063] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown is the embodiment of the four-speed shifting of the single key clutch of the automatic transmission of the present invention, the first gear driving gear 4 is fixed on the gear shaft 1, the second gear driving gear 9, the third gear driving gear 105 and the fourth gear driving gear 106 respectively Assembled on the gear shaft through a single-key clutch, the gear shaft is provided with a chute 102, and a small opening groove is provided in the chute, and the right end of the chute is provided with a deep groove 103 connected with the hollow cavity 104, and the chute is axially distributed with three A feather key through hole and a spring cavity, the feather key through hole on the right is equipped with a feather key 13, the spring 17 is sleeved on the feather key, and the two ends of the spring are in contact with the small hole end face of the feather key through hole and the big end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com