Coil component and manufacturing method thereof

A manufacturing method and coil component technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, electrical components, etc., can solve the problems of increased manufacturing procedures, increased defect rate, and difficult reduction of production costs, and achieve heavy The effect of increasing the overlapping area, improving durability and service life, and not easy to fall off or break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

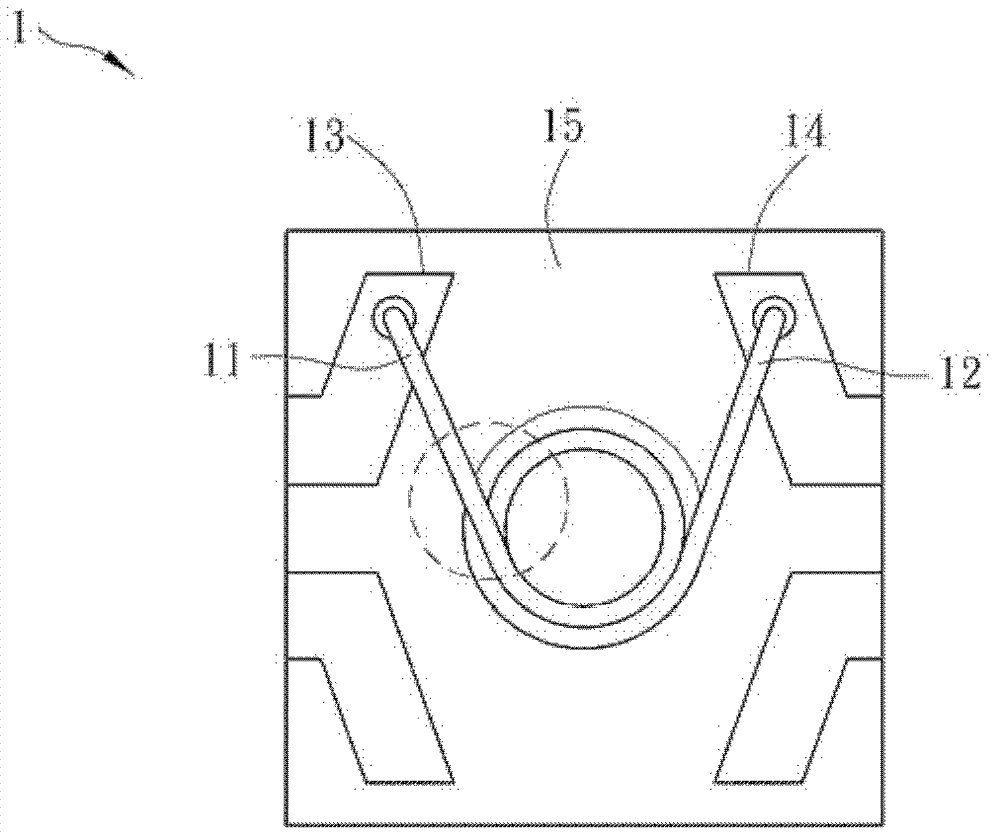

[0045] A coil assembly and a manufacturing method thereof according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference numerals.

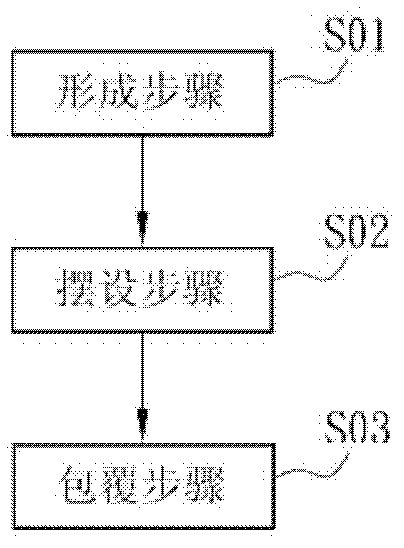

[0046] figure 2 It is a flow chart of a manufacturing method of a coil assembly in a preferred embodiment of the present invention.

[0047] Such as figure 2 As shown, the production method includes the following steps:

[0048] Step S01: a forming step, forming a first coil and a second coil connected to each other, the first coil is located inside the second coil;

[0049] Step S02: an arranging step, arranging a tail end segment of the first stitch on the last segment along the outline of a last segment of the second stitch; and

[0050] Step S03: a covering step, covering the first coil and the second coil.

[0051] The first coil and the second coil are formed by the same wire. The inner layer of the wire is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com