Combined barrier and lubrication fluids pressure regulation system and unit for a subsea motor and pump module

A lubricating fluid and control system technology, applied in the direction of engine lubrication, pump components, mining fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

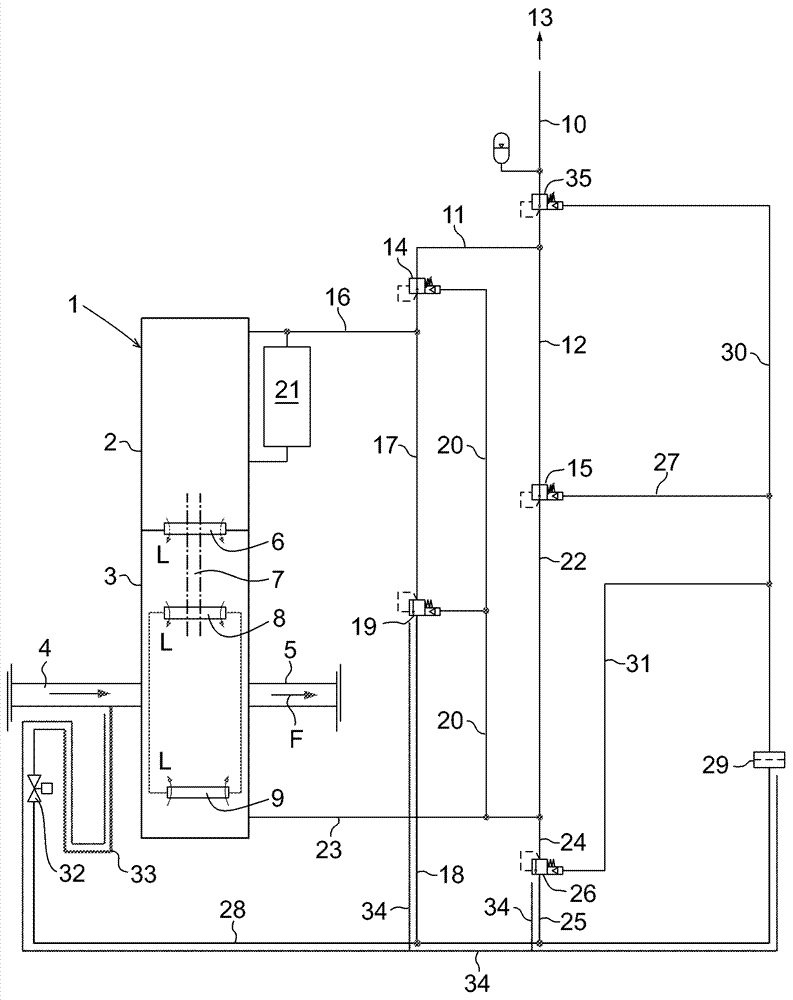

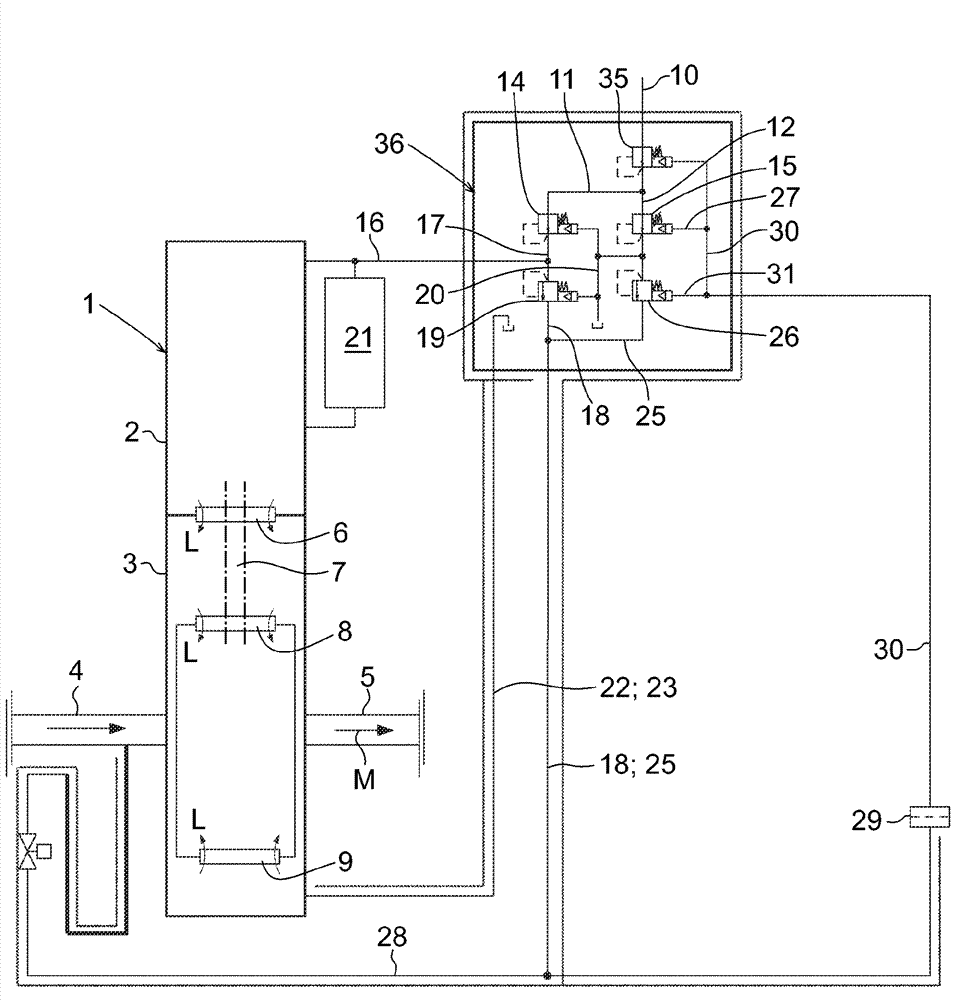

[0040] exist figure 1 In the drawings, reference numeral 1 denotes a subsea motor and pump module comprising a motor enclosed in a watertight pressurized enclosure or motor housing 2 and a pump rotor assembly enclosed in a pump housing 3 . The motor driving the pump is typically an electric motor, but other drive units such as hydraulic motors or turbines may alternatively be employed.

[0041] The pump rotor is configured to displace the pumped medium (typically a multiphase production fluid from a reservoir below the seabed) entering the pump through the pump inlet 4 so that it is expelled through the pump outlet 5, as shown by arrow F like that. The pump rotor is drivingly connected to the motor, and the interior of the pump is hydraulically separated from the pressurized (typically oil-filled) motor housing by means of a sealing arrangement 6 which seals against the rotating shaft (identified by reference numeral 7) on the outside, the pump rotor is connected to the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com