Thin gasket punch forming device

A technology of stamping and forming and gasket, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, time-consuming, and difficulty in arranging and arranging disks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

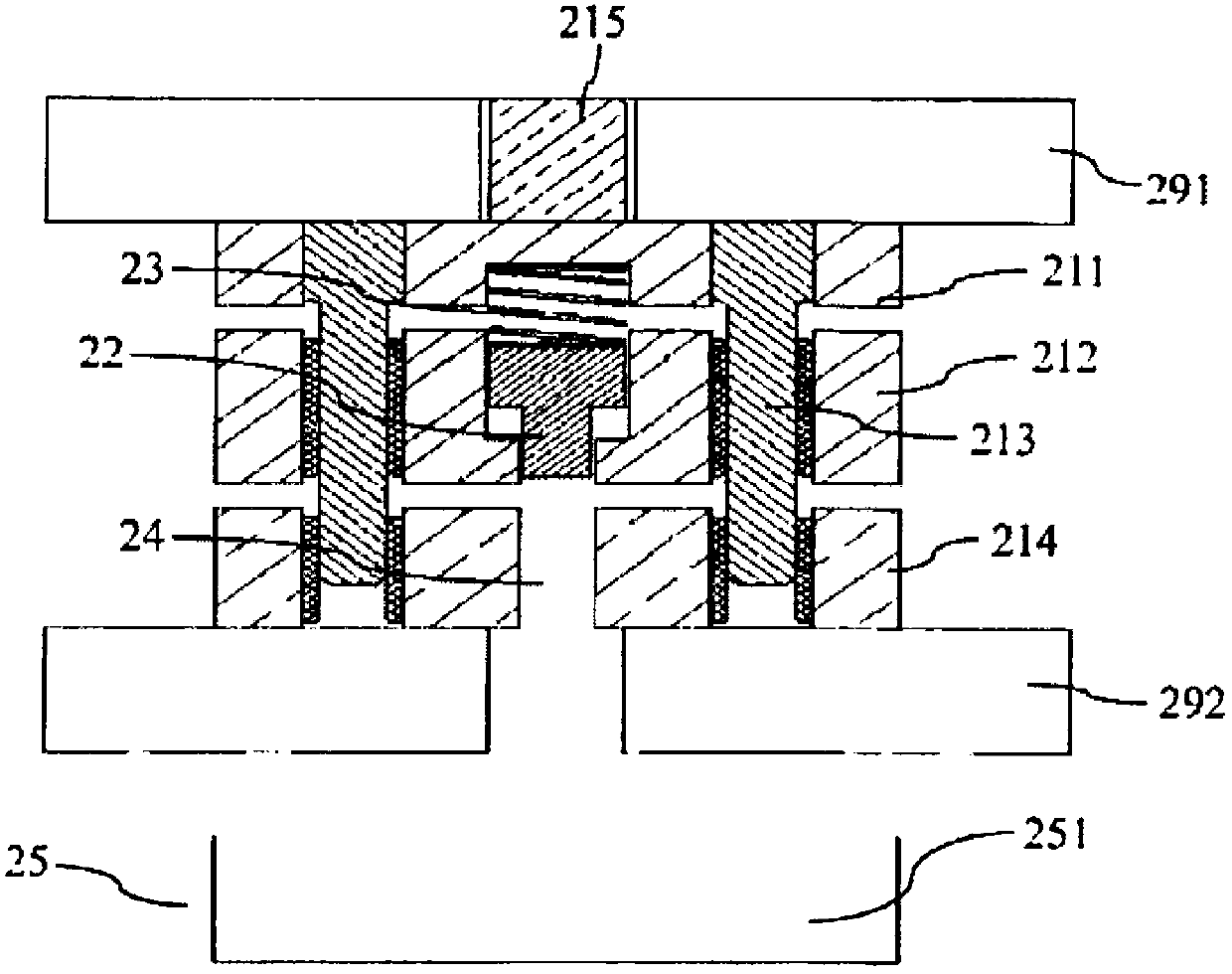

[0027] see Figure 3 to Figure 8 , shown in the figure is the structure and manufacturing method of the selected embodiment of the present invention, which is for illustration only, and is not limited by this embodiment in the scope of protection.

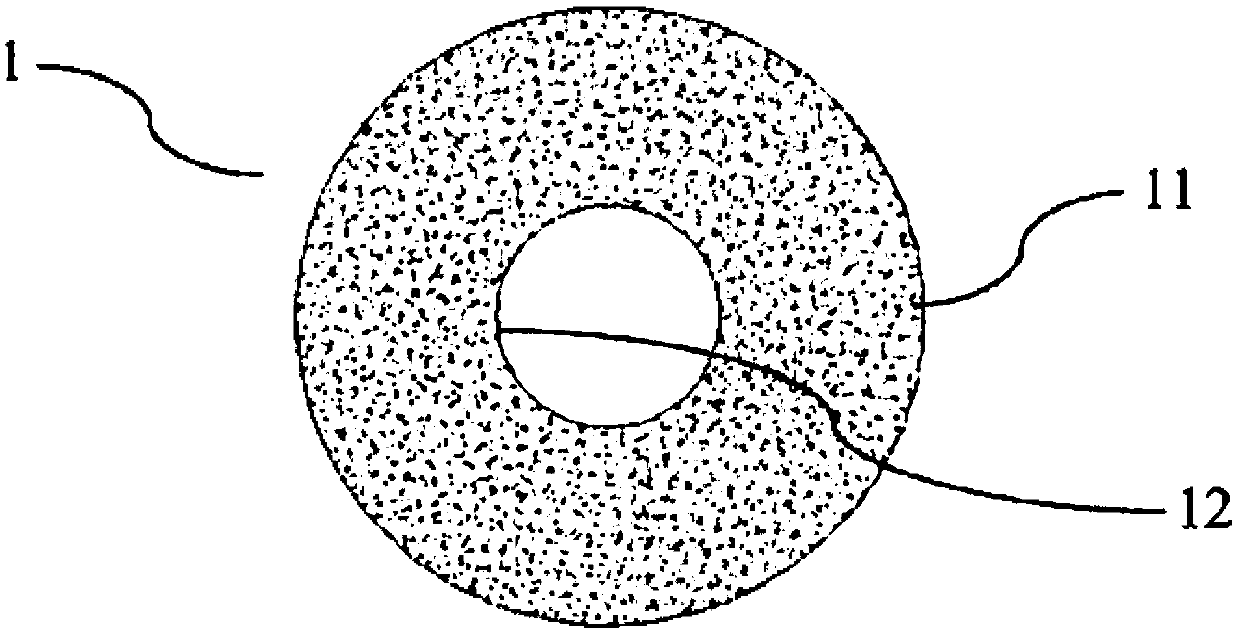

[0028] The present invention is a thin gasket stamping device, which provides strip-shaped material to be fed into a stamping die, and the material is stamped and cut to form a thin gasket, and the punched thin gasket is completely combined with The original strip-shaped material is broken and disconnected, and then through the inner groove of the stamping die and the structure of the feed port and discharge port at both ends, the punched thin gasket, which exits the stamping die The method is to use the original position of the original strip-shaped material to accommodate and enclose the thin gasket, and under the action of feeding on one side of the stamping die and discharging on the other side, by the way, place the thin gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com