A copper surface treatment process for making thick copper-clad laminates

A treatment process and copper surface technology, applied in the field of copper clad laminates, can solve problems such as difficult punching, increased production costs, and reduced product flatness, and achieve improved reliability, excellent adhesion, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

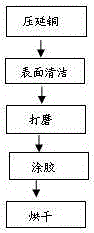

[0012] With reference to the accompanying drawings, a copper surface treatment process for making thick copper-clad laminates comprises the following steps:

[0013] The first step is to use rolled copper to make thick copper-clad laminates made of copper with a thickness of 210um and 400um;

[0014] The second step is to use a combination of copper surface cleaning, grinding and gluing to treat the rolled copper surface. The cleaning treatment is carried out with tetrachlorethylene; after the copper surface is cleaned, it is roughened, and the roughened treatment is polished with an abrasive belt. The method is carried out, and the copper surface roughness Ra reaches 0.6-0.8um by grinding, and the bonding strength between the copper and the substrate is improved; after the copper is polished, the gluing treatment is carried out, and the gluing is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com