Automatic batching charging device of vehicle dismantling pressing block

An automatic feeding device and automobile dismantling technology, which is applied in the fields of motor vehicles, transportation and packaging, and vehicle scrapping and recycling. The effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

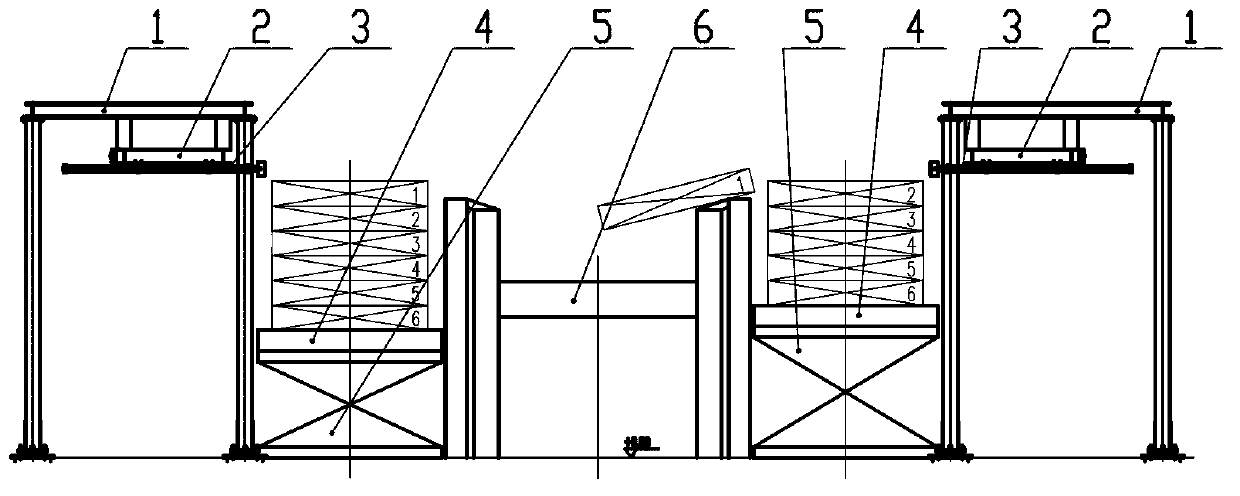

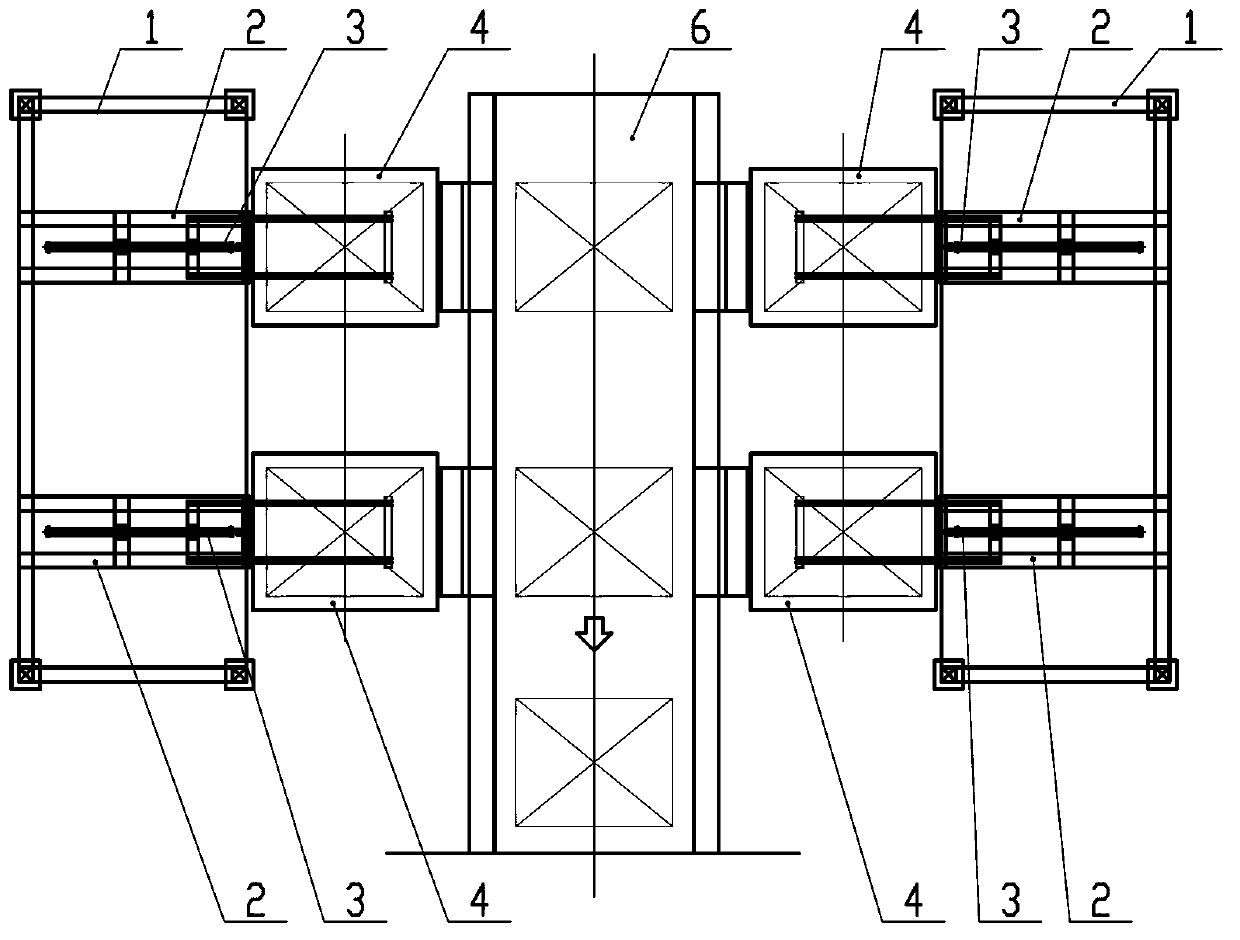

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 , figure 2 Among them, it includes a fixed frame 1, a connecting bracket 2, a pneumatic push rod 3, a wear-resistant plate 4, a lifting platform 5, and a feeding and conveying crawler belt 6, etc.

[0014] Such as figure 1 , figure 2 As shown, the present invention is an automatic feeding device for automobile dismantling briquettes, including a fixed frame 1, a connecting bracket 2, a pneumatic push rod 3 and a lifting platform 5.

[0015] The fixed frame 1 is fixed on the surface of one side of the feeding conveyor belt 6 by bolts, the upper part of the fixed frame 1 is fixed with a connecting bracket 2, and the lower part of the connecting bracket 2 is hung with a pneumatic push rod 3 perpendicular to the feeding conveyor belt 6. The installation height of bar 3 corresponds to the height of feeding conveyor belt 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com