Device for lowering the fuel consumption of the propulsion of a watercraft

A watercraft and power technology, applied in the direction of transportation and packaging, engine components, machines/engines, etc., can solve the problems of large inflow and resistance of the propeller, and achieve the effect of reducing the thickness of the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In the various embodiments shown below, the same components have the same reference numerals.

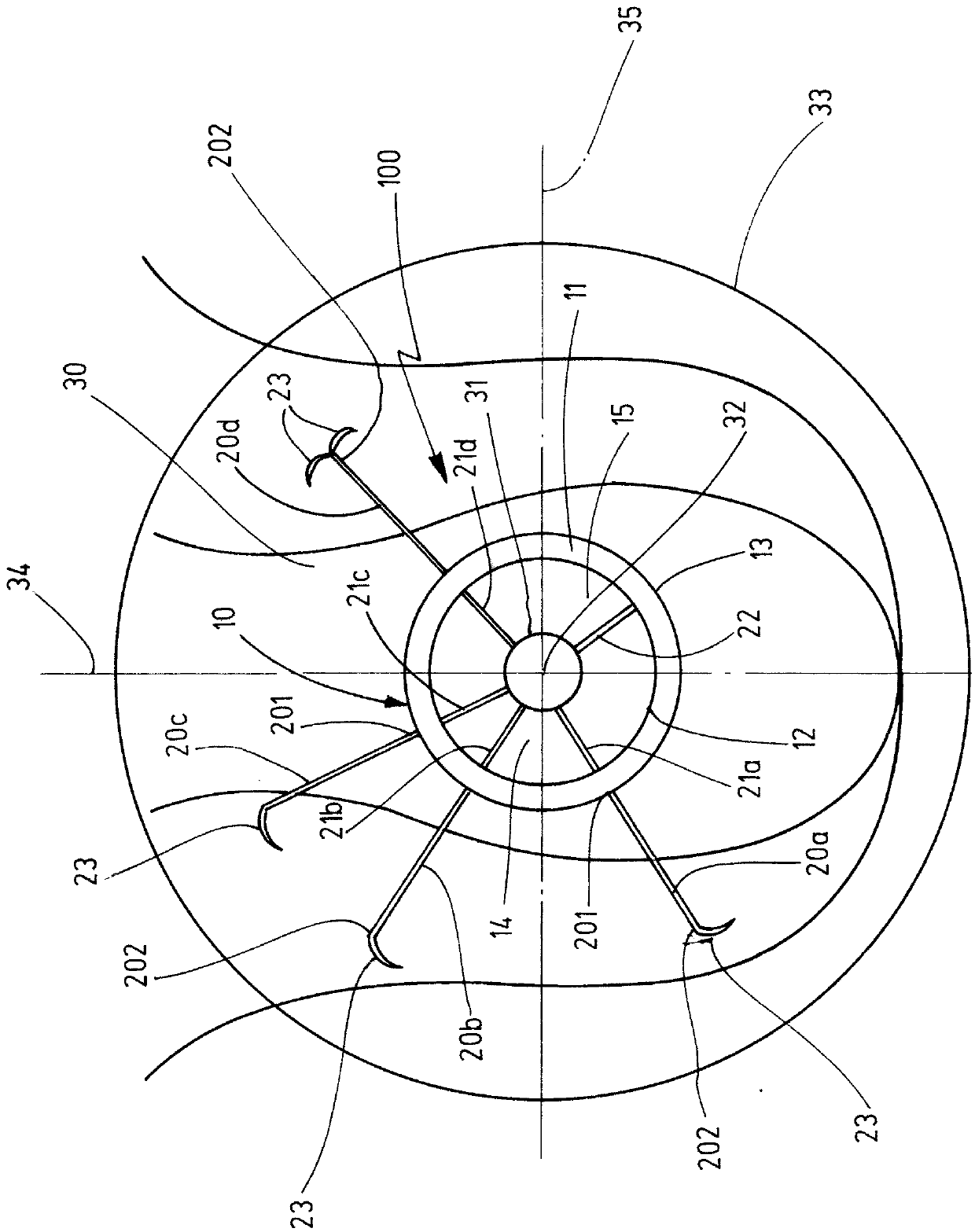

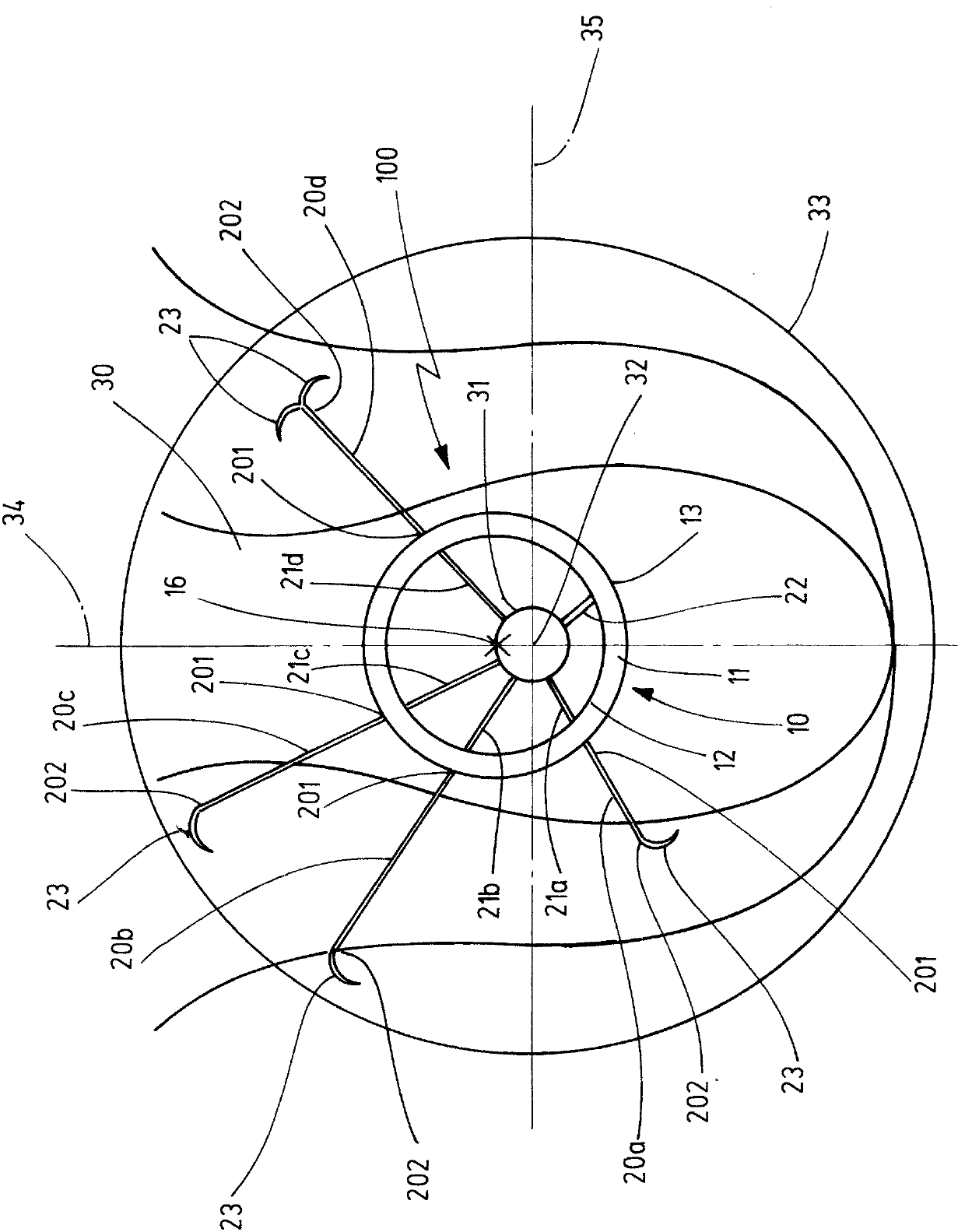

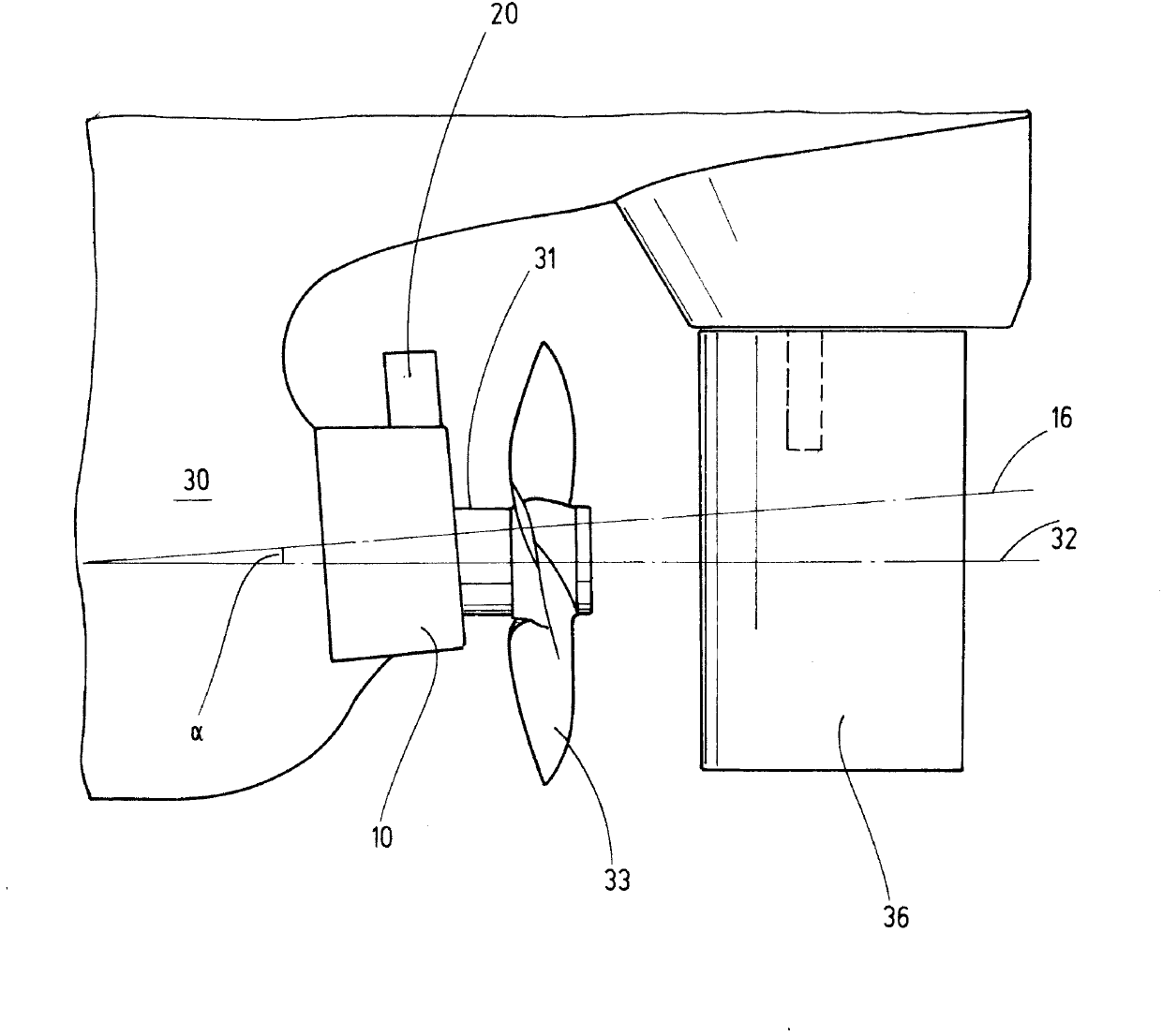

[0082] figure 1 A rear view of the lower rear area of the hull 30 is shown. The bearing 31 is arranged as a shaft tube protruding from the hull 30 in a substantially horizontal direction from the stern. in figure 1 In the figure, the bearing 31 extends from or into the plane of the drawing. A propeller shaft (not shown in the figure) extending along the propeller axis 32 is installed in the bearing 31. in figure 1 In the figure, the propeller axis 32 also extends from or into the plane of the drawing. The propeller axis 32 at the same time forms the longitudinal axis of the front nozzle 10 arranged coaxially with the propeller axis 32. Since the front nozzle 10 in this exemplary embodiment is shown as a rotationally symmetric body, the propeller axis 32 also forms the rotation axis of the front nozzle 10 at the same time. The propeller 33 is only shown schematically as a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com